Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

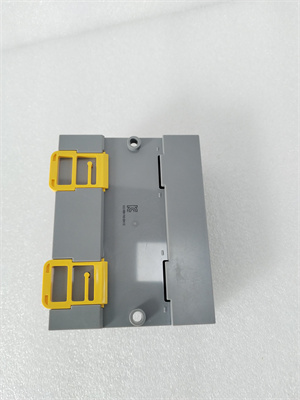

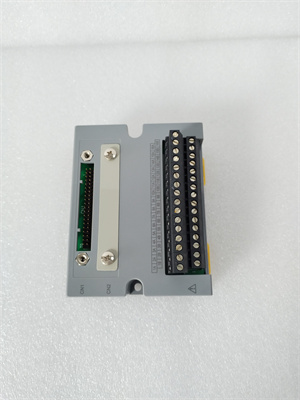

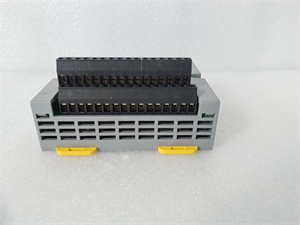

| Product model | YOKOGAWA A1BA4D-05 |

| Manufacturer | Yokogawa |

| Product category | Terminal Board for Analog |

| Operating Voltage | 24V DC |

| Number of Channels | 16 channels x 1 or 8 channels x 1 |

| Input Current | 10mA |

| Communication Interface | RS485 Modbus |

| Operating Temperature Range | -10°C to +60°C |

| Dimensions (W x H x D) | 100 mm x 50 mm x 25 mm |

| Weight | 0.5 kg |

| Certifications | CE, RoHS |

| Protection Rating | IP20 |

yokogawa A1BA4D-05

Product Introduction

The YOKOGAWA A1BA4D-05 is a high-performance terminal board designed for industrial automation and control systems. It provides reliable and accurate signal transmission, making it suitable for a wide range of applications, including sensor signal access and control signal output.

Core Advantages and Technical Highlights

High Precision and Reliability:

The YOKOGAWA A1BA4D-05 offers high-precision signal transmission with a measurement accuracy of ±0.1%. It supports a wide range of input types, including thermocouples, RTDs, linear voltage/current signals, and pulse inputs.

Robust Industrial Design:

The terminal board features an IP20 protection rating, safeguarding it from dust and dirt, making it suitable for harsh industrial conditions.

Versatile Applications:

The YOKOGAWA A1BA4D-05 is suitable for a wide range of applications, including manufacturing, energy, material handling, and robotics.

Easy Integration:

The terminal board supports multiple communication protocols, including RS485 Modbus, ensuring seamless integration with existing systems.

Advanced Safety Features:

The terminal board includes advanced protection mechanisms against overload, short circuit, and overvoltage conditions, enhancing system reliability.

yokogawa A1BA4D-05

Typical Application Scenarios

The YOKOGAWA A1BA4D-05 is widely used in various industrial sectors:

Manufacturing: For precise control in assembly lines and machine tools.

Energy: For monitoring and control in power plants and substations.

Material Handling: For conveyor speed control in automotive assembly lines.

Food and Beverage Production: For controlling heating, cooling, and baking processes.

Related Model Recommendations

YOKOGAWA A1BA4D-10: A similar model with additional features and capabilities, suitable for more complex control tasks.

YOKOGAWA A1BA4D-20: A model with higher power capacity, suitable for applications requiring higher current ratings.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation:

Ensure the installation environment meets the specified temperature and humidity requirements. The terminal board should be installed in a location with adequate ventilation to dissipate heat. Verify that the power supply voltage is within the specified range (24V DC) to avoid damage to the terminal board.

Maintenance Suggestions:

Regularly inspect the installation to ensure the terminal board is securely mounted and all connections are tight. Monitor the operational status of the terminal board to detect any signs of malfunction early. Conduct functional testing on the terminal board at least once a year to ensure optimal performance.

Service and Guarantee Commitment

Yokogawa provides comprehensive support for the YOKOGAWA A1BA4D-05, including a robust warranty that ensures product quality and reliability. The company offers extensive after-sales services such as technical support, repair services, and spare part supply. Yokogawa’s global network of service centers ensures prompt assistance and expert guidance, demonstrating the company’s commitment to customer satisfaction and product excellence.