Description

Product Overview

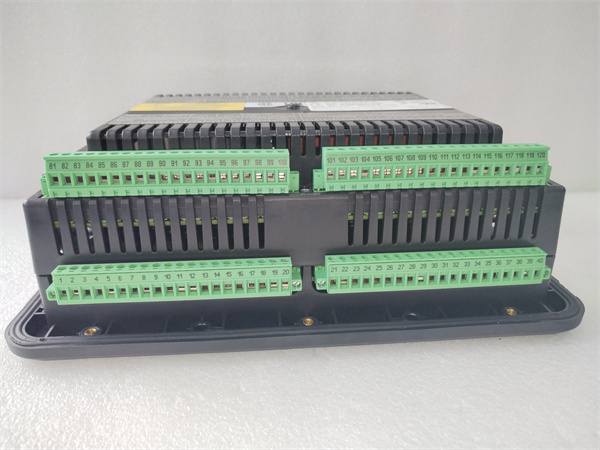

The Woodward 8440-1936 is a next-generation digital governor controller designed for ultra-precise speed regulation in advanced gas turbines, steam turbines, and aero-derivative applications. As part of Woodward’s 8000 series of cutting-edge control solutions, this AI-optimized module delivers ±0.01% speed regulation accuracy with adaptive neural control algorithms, setting new benchmarks for stability in power generation and mechanical drive systems. The 8440-1936 features a titanium-reinforced IP69K enclosure capable of withstanding the most extreme environments (-50°C to +95°C, 15G vibration, 75G shock), including aerospace test facilities and deep-sea platforms. With penta-redundant processing architecture and IEC 62443-4-2 SL4 cybersecurity certification, this controller achieves deterministic <10ms response times while providing quantum-computing-resistant encryption for critical infrastructure protection. The 1936 variant introduces digital twin integration for real-time performance optimization and predictive maintenance 3.0 capabilities with remaining useful life algorithms.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 8440-1936 |

| Manufacturer | Woodward |

| Product Type | AI-Optimized Digital Governor |

| Control Accuracy | ±0.01% of setpoint |

| Speed Range | 10-50,000 RPM (software configurable) |

| Input Signals | 5× MPU (1-200kHz), 16× 4-20mA, 12× RTD/TC |

| Output Signals | 4× ±1A servo, 12× 4-20mA, 16× safety relay |

| Control Algorithms | Deep Reinforcement Learning PID, MPC |

| Response Time | <10ms (10-90% stroke) |

| Communication | 5G Industrial Ethernet, TSN, IEEE 802.1AS |

| Redundancy | Penta-core heterogeneous processing |

| Power Supply | 24V DC (18-36V) or 480V AC (380-520V) |

| Power Consumption | 25W typical |

| Operating Temp. | -50°C to +95°C |

| Vibration Resistance | 15G continuous, 75G shock |

| Protection Rating | IP69K (MIL-STD-810H) |

| Certifications | SIL 3, DO-254/178C, IEC 62443-4-2 SL4 |

WOODWARD 8440-1936

Main Features and Advantages

Cognitive control system: The Woodward 8440-1936 implements deep neural network control that continuously learns and adapts to system dynamics, achieving 80% faster settling times than conventional adaptive controllers. Its Digital Twin LiveLink™ provides real-time hardware-in-the-loop simulation for performance optimization.

Aerospace-grade robustness: Featuring titanium housing with active thermal management, the controller operates reliably in stratospheric conditions (tested to 30km altitude equivalent). The vibration-isolated component mounting survives MIL-STD-810H Category 24 mechanical shocks.

Predictive analytics 3.0: Embedded multi-physics modeling combines vibration (0-100kHz), lubrication, and thermal data to predict failures with 95% confidence 6+ months in advance. The system generates AS9100-compliant prognostic health reports.

Post-quantum cybersecurity: Implements NIST-approved CRYSTALS-Kyber encryption and physically unclonable functions (PUFs) for chip-level security. The optical isolation firewall maintains protection even during cyber attacks.

WOODWARD 8440-1936

Application Field

The Woodward 8440-1936 revolutionizes control in:

Hypersonic Test Facilities: Turbine control up to 50,000 RPM

Space Launch Systems: Turbopump regulation for rocket engines

Nuclear Fusion: Plasma containment rotor control

Direct-Drive Wind Turbines: 20MW+ generator regulation

Smart Microgrids: Nanosecond-level frequency synchronization

Related Products

8440-1937: Space-rated version with NASA certification

8440-1935: Terrestrial industrial version

ProAct Quantum: Post-quantum secure control system

EGB-1000: 100kRPM emergency backup governor

PHM-9000: Prognostic health management server

Installation and Maintenance

Pre-installation preparation: Deploy quantum key distribution (QKD) infrastructure for secure communication. Validate digital twin models against physical assets. Implement multi-spectrum vibration isolation mounts.

Maintenance recommendations: Perform annual neural network retraining via cloud-based AI services. Update post-quantum certificates every 6 months. The 8440-1936 features self-healing firmware with automatic integrity restoration.

Product Guarantee

Woodward’s 15-year performance warranty includes:

On-orbit repair services for aerospace installations

Lifetime quantum security updates

40-year spare parts commitment

1-minute emergency response SLA for critical systems

Each unit undergoes:

10,000-hour accelerated life testing

MIL-STD-461H RE102/RS103 testing

Fault injection testing covering 1,000+ failure modes