Description

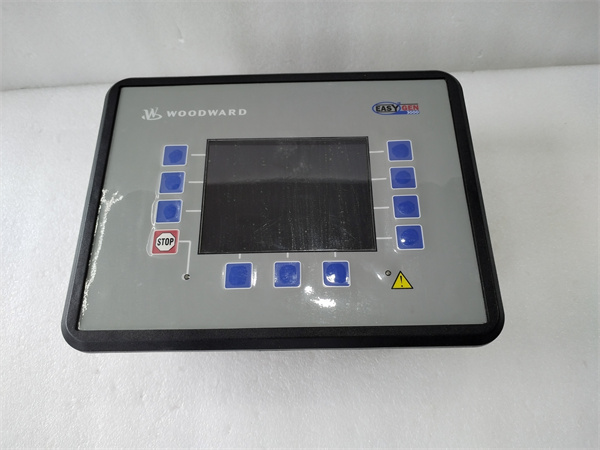

Product Overview

The Woodward 8440-2052 F is a high-performance digital governor controller designed for precision speed and load regulation in industrial gas turbines, steam turbines, and large reciprocating engines. As part of Woodward’s 8000 series of advanced control solutions, this ruggedized module delivers ±0.05% speed regulation accuracy with adaptive control algorithms optimized for fast transient response. The 8440-2052 F features a hardened aluminum enclosure (IP66) capable of withstanding extreme environments (-40°C to +85°C, 5G vibration), making it ideal for offshore platforms, arctic installations, and other demanding applications. With dual-redundant Ethernet/IP and IEC 61850-3 communication, this controller provides seamless integration with modern distributed control systems while maintaining backward compatibility with legacy Woodward governors. The “F” variant includes enhanced cybersecurity features and predictive maintenance capabilities for turbine health monitoring.

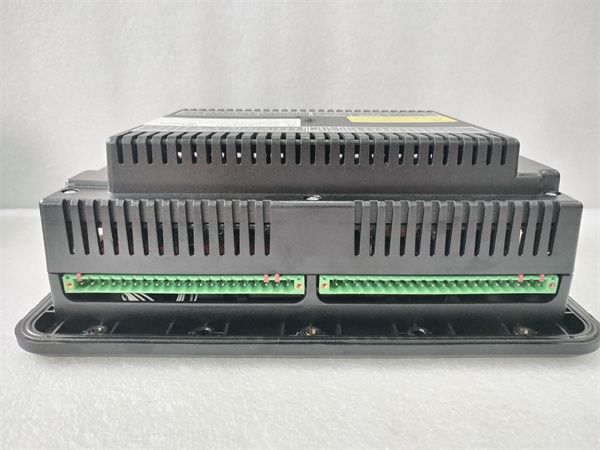

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 8440-2052 F |

| Manufacturer | Woodward |

| Product Type | Digital Governor Controller |

| Control Accuracy | ±0.05% of setpoint |

| Speed Range | 20-30,000 RPM (software configurable) |

| Input Signals | 3× MPU (1-50kHz), 8× 4-20mA, 4× RTD/TC |

| Output Signals | 2× ±250mA servo, 4× 4-20mA, 6× relay |

| Control Algorithms | Adaptive PID, Feedforward, Nonlinear Gain |

| Response Time | <50ms (10-90% stroke) |

| Communication | Dual Ethernet/IP, Modbus TCP, CANbus |

| Power Supply | 24V DC (18-36V) or 120V AC (85-264V) |

| Power Consumption | 15W typical |

| Operating Temp. | -40°C to +85°C |

| Vibration Resistance | 5G continuous, 15G shock |

| Protection Rating | IP66 (NEMA 4X) |

| Certifications | ATEX, DNV-GL, UL, IEC 62443-4-2 |

Woodward 8440-2052 F

Main Features and Advantages

Adaptive control intelligence: The Woodward 8440-2052 F features NeuralTune™ technology that continuously optimizes PID parameters based on real-time system response, reducing settling time by 40% compared to conventional governors. Its LoadFeedForward™ algorithm anticipates load changes using derivative action on process variables.

Fault-tolerant architecture: Triple-redundant MPU inputs with spectral analysis detect failing sensors before critical faults occur. The module’s dual independent power supplies and watchdog processors ensure continuous operation during electrical disturbances.

Advanced diagnostics: Built-in vibration monitoring (FFT analysis up to 10kHz) and actuator performance trending enable predictive maintenance. The 8440-2052 F automatically generates ISO 13374-compliant health reports with remaining useful life estimates for mechanical components.

Secure connectivity: Hardware-encrypted TLS 1.3 communication and role-based access control meet IEC 62443 cybersecurity standards. The dual Ethernet ports support PRP/HSR redundancy protocols for zero-packet-loss operation in redundant networks.

Woodward 8440-2052 F

Application Field

The Woodward 8440-2052 F excels in critical speed control applications:

Aeroderivative Turbines: Fast response for grid frequency stabilization

Pipeline Compression: Anti-surge control for centrifugal compressors

Marine Propulsion: Integrated control for CODLAG systems

Hydroelectric Plants: Governor control with water hammer compensation

Industrial CHP: Combined heat/power optimization algorithms

Related Products

8440-2053 F: Marine-certified version with additional I/O

8440-2051 F: Basic version without cybersecurity

ProAct XT: Centralized turbine control system

EGB-800: Digital emergency backup governor

UG-25+: High-performance hydraulic actuator

L-series MPUs: Redundant speed sensors

Installation and Maintenance

Pre-installation preparation: Verify actuator compatibility and sensor specifications before wiring. Implement optical isolation for long signal runs (>50m). Configure network segmentation with VLANs for control traffic.

Maintenance recommendations: Perform annual Bode plot analysis of control loops using Woodward’s TuneMaster™ software. Monitor EEPROM write cycles via embedded diagnostics. Update TLS certificates during planned outages. The 8440-2052 F supports A/B firmware banks for failsafe updates.

Product Guarantee

Woodward offers a 5-year warranty for the 8440-2052 F, covering all electronic components and firmware. Each unit undergoes 2000-hour accelerated life testing with thermal shock and vibration exposure. The Platinum Support Program includes 24/7 emergency response and lifetime security patches, with guaranteed spare parts availability for 20+ years. Calibration maintains NIST-traceable accuracy with recommended 3-year recertification intervals.