Description

Product Overview

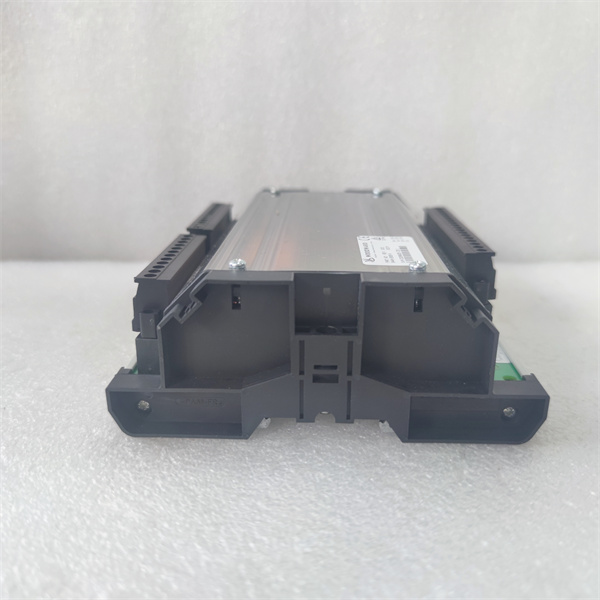

The WOODWARD 8440 – 2028 is a high – performance digital I/O expansion module, designed as an accessory for the user – friendly Woodward easYgen series controllers. It serves a crucial role in enhancing the digital input and output capabilities of control systems, making it highly suitable for a wide array of industrial automation scenarios. As part of the Woodward product family, WOODWARD, a globally recognized leader in industrial control solutions, the 8440 – 2028 inherits the brand’s reputation for quality and reliability.

This module is engineered to seamlessly integrate into various industrial setups. In generator set control applications, it can work in harmony with the main controller to manage the start – stop operations, load sharing, and speed regulation more precisely by providing additional digital control signals. In DCS (Distributed Control System) expansion, it extends the system’s ability to interface with a larger number of field devices, enabling more comprehensive monitoring and control of industrial processes. For industrial automation production lines, the WOODWARD 8440 – 2028 can be used to control the on – off status of motors, sensors, and actuators, ensuring the smooth operation of the entire production process.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 8440 – 2028 |

| Manufacturer | WOODWARD |

| Product Type | Digital I/O Expansion Module |

| Series | easYgen |

| Power Supply | 24 VDC (Some sources also mention compatibility with 12/24 VDC internally isolated power supplies) |

| Number of Digital Inputs | 8 configurable discrete alarm inputs |

| Number of Digital Outputs | 8 configurable form C relays with potential – free contacts |

| Communication Interface | CAN bus (for connection with main genset controller and data transfer), Some sources also mention RS – 485 and Modbus RTU compatibility |

| Operating Temperature | – 40 °C – 85 °C (Some models like the 3200 xt – p 1 version have a range of – 20 °C – 70 °C) |

| Dimensions | 16.8 x 5 x 13 cm (approximate dimensions as per some sources, may vary slightly) |

| Weight | 0.46 kg (approximate weight as per some sources) |

| Protection Level | IP65 (suitable for protection against dust and water jets in industrial environments) |

| Configuration | Smart configuration including alarm class, naming, NO/NC configuration, and time delay, controlled by the main controller via CAN bus |

WOODWARD 8440-2028

Main Features and Advantages

Enhanced I/O Capacity

The WOODWARD 8440 – 2028 significantly boosts the digital I/O capacity of the control system. With 8 discrete alarm inputs and 8 form C relays for outputs, it can interface with a large number of external devices. For example, in a complex industrial plant, it can connect to various sensors such as temperature sensors, pressure sensors, and limit switches on the input side. On the output side, it can control solenoid valves, contactors, and small – power motors, enabling more comprehensive control over the industrial process.

Smart Configuration

This module offers intelligent configuration options. Each input can be assigned a name, alarm class, NO/NC (normally open/normally closed) configuration, and time delay. The configuration is easily managed through the main controller’s relay manager and transmitted to the 8440 – 2028 via CAN bus. This flexibility allows users to customize the module according to the specific requirements of their industrial applications. For instance, in a power generation system, different input signals can be classified into different alarm classes, and the time delay can be adjusted to avoid false alarms caused by short – term signal fluctuations.

Wide Compatibility

The 8440 – 2028 is highly compatible. It is designed to work in tandem with a range of Woodward devices, such as power automatic transferors, input – output controllers, and generator load controllers. Additionally, it can also be used with controllers from other manufacturers in some cases, as long as they support the CAN bus communication protocol. This makes it a versatile choice for upgrading or expanding existing industrial control systems, regardless of the brand of the main controller.

Robust Design

Built to endure harsh industrial environments, the WOODWARD 8440 – 2028 has a protection level of IP65. It can withstand dust, water jets, and extreme temperatures within its operating range. Whether in a dusty cement factory or a high – humidity food processing plant, the module can maintain stable operation, reducing the risk of system failures due to environmental factors and ensuring long – term reliable performance.

Application Field

Generator Set Control

In generator set applications, the WOODWARD 8440 – 2028 is used to enhance the control system’s functionality. It can be used to monitor and control various parameters related to the generator set, such as the status of the engine, the output voltage and frequency of the generator, and the load sharing among multiple generator sets. For example, in a data center’s backup power system, the module can detect when the mains power fails and quickly send signals to start the generator set. It can also adjust the generator’s output to match the load demand, ensuring a stable power supply for the data center’s critical IT equipment.

DCS Expansion

For DCS systems, the 8440 – 2028 serves as an expansion module. It enables the DCS to connect to more field devices, increasing the system’s monitoring and control scope. In a chemical plant, the DCS can use this module to interface with additional sensors and actuators in the production process. This allows for more detailed control of chemical reactions, such as adjusting the flow rate of reactants, controlling the temperature of reactors, and monitoring the quality of products in real – time.

Industrial Automation Production Lines

On industrial automation production lines, the WOODWARD 8440 – 2028 plays a vital role in controlling the operation of equipment. It can be used to control the movement of conveyor belts, the activation of robotic arms, and the start – stop of production machines. In an automotive manufacturing plant, the module can be used to control the assembly line equipment. For example, it can ensure that the robotic arms pick and place car parts at the right time and position, and control the conveyor belts to move the semi – finished products smoothly between different production stations, improving the overall production efficiency and product quality.

WOODWARD 8440-2028

Related Products

WOODWARD 8440 – 1936 (easYgen – 3500 – 5 – P2)

This is a generator set controller in the easYgen series. It can be used in combination with the 8440 – 2028 in a power generation system. The 8440 – 1936 is mainly responsible for overall genset control, such as starting and stopping the gensets based on load dependencies, while the 8440 – 2028 can be used to expand the digital I/O capabilities for more detailed control of auxiliary equipment or for interfacing with additional sensors and actuators in the genset setup.

WOODWARD 8440 – 1713/D

A control module that focuses more on speed control, load sharing, and governor control for engines and turbines. In an industrial power system where engines or turbines are used for power generation, the 8440 – 1713/D can work together with the 8440 – 2028. The 8440 – 1713/D manages the main control functions related to the engine or turbine operation, and the 8440 – 2028 can be used to expand the control system’s ability to interface with other devices in the system, such as sensors for monitoring engine temperature or vibration.

WOODWARD 8273 – 1011

Although specific details about its function in relation to the 8440 – 2028 are limited, it is likely to be a related control or interface component. It may offer additional communication or control features that can be integrated with the 8440 – 2028 to improve the overall performance and connectivity of the industrial control system. For example, it could enhance the communication speed or range between the 8440 – 2028 and other devices in the network.

WOODWARD easYgen – 3000 Series Controllers (other models)

These controllers share the same series with the 8440 – 2028. Different models in the series may have different levels of functionality, input/output capabilities, or communication interfaces. The 8440 – 2028 can be used to expand the I/O capabilities of these controllers, regardless of their specific model. For example, a base easYgen – 3000 series controller with limited I/O can be enhanced by adding the 8440 – 2028 to interface with more field devices in an industrial application.

Direct Configuration Cable (DPC) and Associated Software

These are accessories for the WOODWARD 8440 – 2028. The DPC and software are useful for configuring the module, especially for complex or large – scale configuration tasks. When multiple 8440 – 2028 units need to be set up in an industrial system, the DPC and software can simplify the process by allowing for easy configuration through a PC or laptop, rather than relying solely on the configuration via the main controller’s CAN bus interface.

Installation and Maintenance

Pre – installation preparation: Before installing the WOODWARD 8440 – 2028, carefully read the detailed installation manual provided by WOODWARD. Ensure that the power supply at the installation site meets the 24 VDC requirement (or other specified voltage ranges depending on the model). Prepare all the necessary cables and connectors for connecting the module to the main controller, sensors, and actuators. Select an appropriate installation location that is well – ventilated, free from excessive dust and moisture, and within the specified – 40 °C – 85 °C temperature range (or relevant temperature range for the specific model). Mount the module securely using the provided brackets and follow the wiring diagram precisely to ensure proper connections. Make sure to check the CAN bus settings and ensure compatibility with the main controller’s communication protocol.

Maintenance recommendations: Regularly inspect the WOODWARD 8440 – 2028 for any signs of physical damage, such as cracks in the housing or loose connectors. Clean the module’s exterior periodically to keep it free from dust, which could affect its performance in a dusty industrial environment. Monitor the power supply voltage regularly to ensure it remains stable within the rated range. Use the built – in diagnostic functions (if available) or the associated software tools to perform routine health checks. Check the communication status with the main controller via the CAN bus to ensure seamless data transfer. If any abnormal behavior is detected, such as incorrect input readings or output failures, refer to the troubleshooting guide in the product manual or contact WOODWARD’s technical support team for assistance. Also, keep the module’s firmware updated to benefit from the latest performance improvements and bug fixes.

Product Guarantee

WOODWARD stands firmly behind the quality of the WOODWARD 8440 – 2028. The product undergoes rigorous testing during the manufacturing process to meet the highest industry standards. WOODWARD offers a comprehensive warranty, during which, in case of any defect due to faulty materials or workmanship, the company will provide free repair or replacement services. Their dedicated technical support team is available to assist customers with installation, operation, and maintenance issues. Whether it’s providing remote diagnostic support or on – site service, WOODWARD is committed to ensuring that customers can rely on the 8440 – 2028 for their industrial control needs. This reflects the company’s confidence in the product’s quality and durability, and its commitment to customer satisfaction.