Description

System Role and Integration

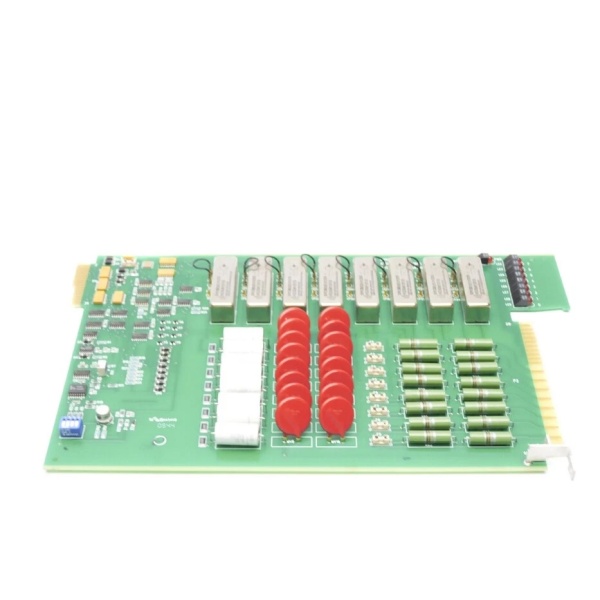

The 3A99168G01 serves as the high-voltage discrete output interface within the Westinghouse Q-Line distributed I/O architecture, functioning as the critical switching element between controller logic commands and field devices operating at elevated voltages. As a QRO (Q-Line Relay Output) card designated 8QRO1, it mounts in standard Q-Line I/O chassis and communicates via the proprietary Q-Line parallel bus to receive actuation commands from the main control processor.

This module occupies a crucial position in legacy power generation and heavy industrial control systems, providing the electromechanical isolation and high-voltage switching capability necessary for controlling solenoid valves, motor contactors, alarm annunciators, and indicating lamps that require voltages and currents beyond the capacity of solid-state logic outputs. The card integrates directly with the Q-Line backplane, allowing seamless replacement of earlier 2840A18G01 relay output cards without chassis or configuration modifications.

Core Functionality and Signal Handling

The module houses eight independent electromechanical relays configured with Form A (single-pole single-throw normally open) contacts, capable of switching loads up to 330VDC or 250VAC. Each channel provides complete galvanic isolation between the controller logic and field circuits, protecting sensitive digital electronics from ground faults, voltage transients, and electromagnetic interference prevalent in industrial switchgear environments.

The 3A99168G01 accepts low-voltage logic commands from the Q-Line controller and energizes the corresponding relay coils to close the field contacts. Status feedback to the controller indicates successful relay actuation, enabling interlock verification and diagnostic monitoring. The relay contacts are rated for resistive, inductive, and lamp loads common in power plant auxiliary systems, with arc suppression and contact protection features ensuring reliable operation across the rated voltage range.

Platform Heritage and Operational Benefits

As a component of the Westinghouse Q-Line I/O family—the direct predecessor to the modern Ovation distributed control system—the 3A99168G01 reflects the ruggedized design philosophy developed for mission-critical turbine control and power generation applications. The card serves as a functional replacement and spare parts continuity solution for the earlier 2840A18G01 QRO modules, allowing facilities with mature Q-Line installations to maintain operational availability without immediate migration to newer platforms.

The electromechanical relay architecture provides distinct advantages over solid-state alternatives in high-voltage applications, including inherent isolation, visual contact status indication, and tolerance to voltage surges and momentary overloads that would damage transistorized outputs. The 330VDC rating specifically addresses the needs of legacy 125VDC and 250VDC control circuits common in power plant breaker control, turbine auxiliary systems, and switchyard interlocking schemes.

Part 4: Technical Specifications

-

Model Number: 3A99168G01

-

Manufacturer: Westinghouse Electric Corporation (Process Control Division)

-

Product Type: Q-Line Relay Output Card (QRO)

-

Q-Line Designation: 8QRO1 (QRO G01 Series)

-

Number of Channels: 8 isolated electromechanical relay outputs

-

Contact Configuration: Form A (SPST-NO – Single Pole Single Throw Normally Open)

-

Maximum Switching Voltage: 330VDC / 250VAC

-

Contact Rating: High-voltage switching suitable for solenoid valves, contactors, and indicating devices

-

Isolation: Complete galvanic isolation between field contacts and controller logic

-

Backplane Interface: Q-Line proprietary parallel bus (Q-rack compatible)

-

Status Indication: Individual relay status feedback to controller

-

Operating Temperature: 0°C to 60°C (32°F to 140°F)

-

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

-

Humidity: 0% to 95% RH (non-condensing)

-

Dimensions: Approximately 16 cm × 16 cm × 12 cm (PCB assembly)

-

Weight: 0.11 kg to 1.0 kg (depending on packaging)

-

Substitutes For: 2840A18G01 (legacy QRO G01 cards)

-

Mounting: Plug-in card for Q-Line I/O chassis

-

Certifications: CE Mark compliant

WESTINGHOUSE 3A99168G01

Part 5: Core Features & Customer Value

High-Voltage Switching Capability: The 330VDC/250VAC rating enables direct control of legacy power plant auxiliary devices without interposing relays. For maintenance engineers, this simplifies panel wiring, reduces component count, and eliminates potential failure points associated with external relay coils and sockets, while providing the voltage compatibility necessary for 125VDC trip circuits and 250VDC indicating applications common in switchyard control schemes.

Electromechanical Reliability: Unlike solid-state outputs susceptible to voltage transients and thermal runaway, the electromechanical relays tolerate the high-voltage spikes and momentary overloads characteristic of inductive load switching. This robustness translates to extended service life in harsh electrical environments, reducing the frequency of output card replacements and associated process interruptions during critical generation periods.

Direct Legacy Compatibility: The 3A99168G01 functions as a drop-in replacement for the earlier 2840A18G01 relay output cards, utilizing identical chassis mounting, backplane connections, and functional characteristics. For facilities managing Q-Line spare parts inventories, this compatibility ensures that replacement stock remains available even as original Westinghouse manufacturing ceased, supporting long-term operational continuity for legacy turbine control and boiler management systems.

Galvanic Isolation and Safety: Each relay provides complete electrical separation between the low-voltage controller logic and high-voltage field circuits, ensuring that ground faults or insulation failures in field wiring cannot propagate to damage the expensive control processor or create safety hazards for maintenance personnel. This isolation proves critical in switchyard applications where field devices operate at battery voltages up to 250VDC, far exceeding safe touch potentials.

Visual Diagnostic Capability: The electromechanical construction allows technicians to observe relay actuation through contact status indication or coil energization indicators, providing immediate visual confirmation of output states during troubleshooting. This visibility eliminates the need for specialized test equipment to verify output integrity, accelerating fault diagnosis during outage periods and reducing mean time to repair (MTTR).

Part 6: Typical Applications

Power Plant Breaker and Switchgear Control: The 3A99168G01 is extensively deployed in fossil fuel and nuclear generating stations for control of medium-voltage breaker close/trip circuits and switchgear motor operators. The 330VDC rating accommodates the 125VDC and 250VDC battery systems standard in power plant auxiliary control, directly driving breaker trip coils without external interposing relays, while the Form A configuration provides the fail-safe normally-open logic required for non-latching control schemes.

Turbine Auxiliary and Safety Systems: Within steam and gas turbine control cabinets, this module manages emergency trip solenoids, lubricating oil system valves, and hydrogen seal oil equipment. The high-voltage capability interfaces directly with legacy turbine trip devices and auxiliary system contactors, providing hardwired control paths that remain functional even during control system diagnostic or maintenance activities that might affect electronic outputs.

Switchyard Interlocking and Annunciation: In high-voltage substation control houses and switchyard interface cabinets, the card drives indicating lamps, alarm horns, and interlocking relays operating at 125VDC or 250VDC. The robust relay contacts handle the inductive loads of large indicating devices and auxiliary relays, while the isolation prevents ground potential rise during fault conditions from affecting sensitive microprocessor-based control systems.

Legacy Control System Maintenance: For facilities continuing to operate mature Q-Line installations in power generation, pulp and paper, or petrochemical applications, the 3A99168G01 provides critical sparing for relay output modules originally installed in the 1980s and 1990s. Its availability through secondary markets ensures that unplanned card failures do not force premature total system migrations, allowing capital improvement planning on scheduled rather than emergency bases.

Process Safety and Emergency Shutdown: In safety instrumented functions requiring hardwired relay logic—such as boiler fuel master trips or turbine overspeed protection—the module provides the final output element for de-energize-to-trip architectures. The electromechanical relays offer positive visual indication of safety system status during testing and maintenance, and their isolation ensures that faults in the digital control system cannot inadvertently energize safety outputs.