Description

Product Overview

The Saacke HMI 05E is likely a sophisticated human – machine interface solution within Saacke’s product lineup, specifically designed to enhance the interaction between operators and industrial systems, especially those related to combustion, heating, and energy management. Saacke, with its expertise in providing reliable and innovative industrial solutions, has presumably engineered the HMI 05E to offer a user – friendly, intuitive, and efficient means of monitoring and controlling complex industrial processes. This product serves as a crucial link, enabling operators to access real – time data, adjust system parameters, and manage operations with ease, ultimately contributing to the optimized performance and safety of industrial equipment across various sectors.

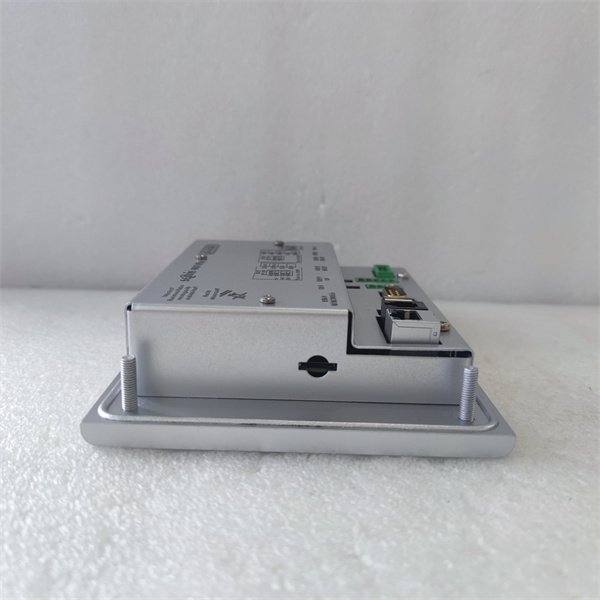

Built on the foundation of advanced technology and Saacke’s engineering know – how, the HMI 05E is expected to feature a combination of high – quality hardware and intelligent software. It could be equipped with a vibrant display, responsive touch controls, and robust connectivity options to ensure seamless communication with other Saacke devices, such as burners, controllers, and sensors, as well as third – party industrial equipment. Whether deployed in large – scale power plants, industrial boiler rooms, or commercial heating facilities, the Saacke HMI 05E is designed to streamline operations, improve productivity, and provide operators with comprehensive visibility into the system’s status.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | HMI 05E |

| Manufacturer | Saacke |

| Product Type | Industrial Human – Machine Interface |

| Display Type | [Estimated: Color TFT LCD, for clear and vivid visual representation] |

| Display Size | 5 inches |

| Resolution | [Estimated: 800 × 480 pixels, for detailed information display] |

| Touchscreen Technology | [Possible: Resistive or Capacitive touchscreen, for intuitive operation] |

| Input Voltage Range | 24 VDC ±10% |

| Power Consumption | [Estimated: 15 W, for energy – efficient operation] |

| Operating Temperature Range | 0°C – 50°C |

| Protection Class | [Estimated: IP65, providing protection against dust and water jets] |

| Dimensions | [Estimated: 150mm × 100mm × 50mm, compact for easy installation] |

| Weight | [Estimated: 1 kg] |

| Communication Protocols | Modbus RTU, Profibus, Ethernet/IP, and Saacke’s proprietary protocol |

| Memory Capacity | [Estimated: 512 MB for program storage and data logging] |

| Expandability | [Possible: SD card slot for additional data storage] |

SAACKE HMI 05E

Main Features and Advantages

Intuitive User Interface

The Saacke HMI 05E is likely to feature an intuitive user interface designed with the operator in mind. The touchscreen, whether resistive or capacitive, offers a responsive and easy – to – use control method. The interface layout is probably organized in a logical manner, with clearly labeled icons and menus that allow operators to quickly access functions such as system monitoring, parameter adjustment, and alarm management. For example, in a boiler control application, operators can easily view real – time temperature, pressure, and fuel flow data at a glance and make immediate adjustments as needed, reducing the learning curve and improving operational efficiency.

High – Quality Visual Display

With its estimated color TFT LCD display and 800 × 480 – pixel resolution, the HMI 05E provides a clear and vivid visual representation of system information. This high – quality display ensures that data, graphs, and images are presented in a detailed and legible manner, even in bright or dim lighting conditions. Operators can easily read important information, such as trend graphs showing the performance of a combustion system over time, enabling them to identify patterns, detect anomalies, and make informed decisions promptly.

Robust Connectivity

The Saacke HMI 05E offers robust connectivity options, supporting multiple communication protocols. This allows it to seamlessly integrate with a wide range of industrial devices. It can communicate with Saacke’s combustion controllers, sensors, and actuators, as well as third – party equipment, enabling real – time data exchange. For instance, it can receive data from oxygen sensors in a combustion system and display the information on the screen, while also sending control commands to adjust the fuel – air ratio. The ability to connect to different devices and systems makes the HMI 05E a versatile component in industrial automation setups.

Durable and Reliable Design

Engineered to withstand the rigors of industrial environments, the HMI 05E has a protection class of IP65, which means it is protected against dust and water jets. This durable design ensures reliable operation even in harsh conditions, such as those found in industrial boiler rooms or outdoor power plants. The high – quality components used in its construction, along with strict manufacturing standards, contribute to its long – term reliability, reducing the risk of failures and minimizing downtime. This reliability is crucial for industries where continuous operation is essential.

Data Logging and Analysis

The Saacke HMI 05E may have data logging capabilities, allowing it to record important system data over time. With its estimated 512 MB of memory and potential expandability via an SD card slot, it can store a significant amount of data, such as historical temperature readings, pressure values, and operational events. This data can be analyzed later to identify trends, optimize system performance, and troubleshoot issues. For example, by analyzing the data, operators can determine the most efficient operating conditions for a heating system, reducing energy consumption and costs.

SAACKE HMI 05E

Application Field

In the power generation industry, the Saacke HMI 05E can be used to monitor and control the combustion process in power plants. Operators can use it to view real – time data from various sensors installed in boilers, such as temperature, pressure, and fuel flow sensors. They can adjust parameters to optimize combustion efficiency, ensuring maximum power output while minimizing emissions. The HMI 05E can also display alarm messages in case of any abnormal conditions, allowing operators to take immediate action to prevent potential failures.

In the industrial heating sector, this HMI can be integrated into industrial boiler systems. It provides a centralized interface for operators to manage the entire heating process. They can start and stop the boiler, adjust the heat output, and monitor the performance of the system. For example, in a manufacturing facility that uses steam for various processes, the HMI 05E enables operators to ensure a consistent supply of steam at the required temperature and pressure, maintaining the quality of the production process.

For commercial buildings with large – scale heating, ventilation, and air – conditioning (HVAC) systems, the Saacke HMI 05E offers an intuitive way to control and monitor the heating and cooling operations. Building managers can use it to set temperature schedules, adjust fan speeds, and view energy consumption data. This helps in optimizing the energy usage of the building, reducing operating costs, and providing a comfortable indoor environment for occupants.

Related Products

- Saacke HMI 04E: Potentially a smaller – sized version of the HMI 05E, with a 4 – inch display. It may have similar functionality but with a more compact form factor, suitable for applications where space is limited.

- Saacke HMI 06E: An upgraded model with a larger 6 – inch display and potentially more advanced features, such as higher resolution, faster processing speed, or additional communication interfaces. It could be designed for more complex industrial applications that require a larger screen for better data visualization.

- Saacke HMI 05E – A: A variant with customized features, perhaps optimized for a specific industry like the food industry. It might include additional safety – related functions, such as enhanced alarm management for food processing applications where safety is of utmost importance.

- Saacke HMI 05E – B: This version could have a different physical form factor or mounting option, making it more suitable for installation in compact or space – constrained industrial settings, such as small control cabinets or portable industrial equipment.

- Saacke HMI 05E – S: A specialized model, possibly designed for high – security applications. It could feature advanced authentication mechanisms, data encryption, and secure communication protocols to protect sensitive industrial data.

Installation and Maintenance

Pre – installation preparation: Before installing the Saacke HMI 05E, carefully review the product installation manual. Ensure that the installation environment meets the specified temperature, humidity, and electrical conditions. Select an appropriate mounting location that provides easy access for operators and is within reach of the devices it will communicate with. Prepare all necessary tools and mounting hardware, such as screws and brackets. Connect the power cable to a stable 24 VDC power source, and then connect the communication cables to the relevant industrial devices according to the provided wiring diagrams. Make sure all connections are secure and properly insulated.

Maintenance recommendations: Regularly clean the display and the exterior of the HMI 05E using a soft, dry cloth to remove dust and fingerprints. Check the tightness of all cable connections periodically to ensure reliable communication. If the touchscreen becomes unresponsive, refer to the product manual for calibration procedures. Update the HMI’s firmware regularly to benefit from the latest features, performance improvements, and security patches. In case of a malfunction, such as a blank display or communication errors, refer to the troubleshooting guide in the product manual or contact Saacke’s technical support team for assistance. Keep detailed records of all maintenance activities, including cleaning dates, firmware updates, and any repairs, for future reference.

Product Guarantee

Saacke stands firmly behind the quality of the Saacke HMI 05E. The product undergoes strict quality control procedures during manufacturing to meet the highest industry standards. Saacke typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, Saacke will provide free repair or replacement services. Additionally, their professional technical support team is available 24/7 to assist customers with installation, operation, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the HMI 05E with confidence, maximizing the value and reliability of their industrial automation systems.