Description

Detailed parameter table

| Parameter name | Parameter value |

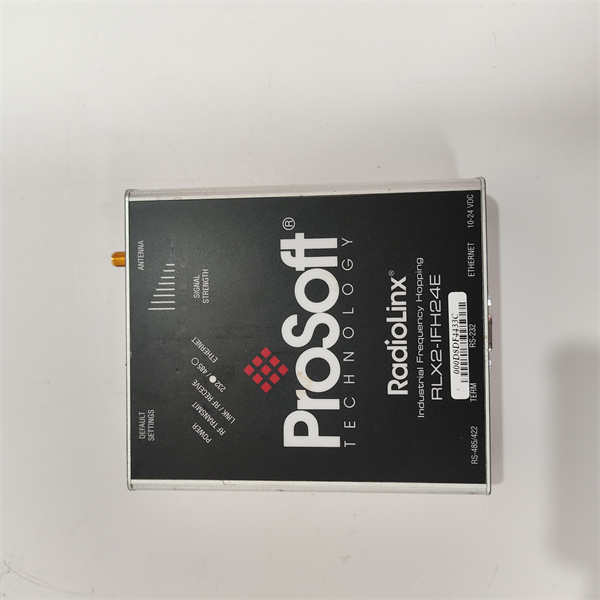

| Product model | PROSOFT RLX2-IFH24E |

| Manufacturer | ProSoft Technology |

| Product category | Industrial Wireless Ethernet Module (IEEE 802.11 a/b/g/n, 2.4/5 GHz dual-band) |

| Compatible Devices | Ethernet/IP devices: Allen-Bradley ControlLogix/CompactLogix PACs, PowerFlex VFDs, HMIs; Modbus TCP devices: Third-party sensors, meters, PLCs; Other Ethernet-enabled industrial equipment |

| Supported Protocols | IEEE 802.11 a/b/g/n (dual-band: 2.4 GHz, 5 GHz); Ethernet/IP (explicit/implicit messaging); Modbus TCP; SNMP (for network management); WPA2-Enterprise/WPA2-PSK (wireless security) |

| Communication Interfaces | 2x 10/100/1000 Mbps RJ45 Ethernet ports (PoE/PoE+ support, 802.3af/at); 1x RP-SMA antenna connector (external antenna included); 1x micro-USB (configuration/debug); Link/activity/wireless status LED indicators (color-coded) |

| Wireless Performance | Data rate: Up to 300 Mbps (5 GHz, 802.11n); Transmission range: Up to 500 meters (line-of-sight, external antenna); Receiver sensitivity: -94 dBm (2.4 GHz, 1 Mbps), -92 dBm (5 GHz, 1 Mbps); Channel bandwidth: 20/40 MHz (2.4 GHz), 20/40/80 MHz (5 GHz) |

| Power Requirements | Power supply: 48 VDC PoE/PoE+ (via Ethernet port) / 12-24 VDC external (redundant); Current consumption: < 150 mA (24 VDC, operating mode), < 20 mA (low-power standby); PoE power class: Class 2 (802.3af) |

| Physical Dimensions | DIN rail-mountable (TS 35/7.5); 120 mm (height) × 75 mm (width) × 100 mm (depth); Weight: ~420 g; Housing rating: IP30 (cabinet-mounted), optional IP65 enclosure (outdoor use) |

| Environmental Ratings | Operating temperature: -30 °C to +70 °C; Storage temperature: -40 °C to +85 °C; Relative humidity: 5%–95% (non-condensing, 40 °C dew point); Vibration resistance: 5 g (10–500 Hz, IEC 60068-2-6); Shock resistance: 30 g (11 ms half-sine, IEC 60068-2-27); EMC compliance: EN 61000-6-2 (immunity), EN 61000-6-3 (emissions) |

| Configuration Tools | ProSoft Wireless Configuration Utility (PWCU) v4.0+ (graphical wireless setup, site survey); Web-based management interface (HTTP/HTTPS); Rockwell Studio 5000 integration (via EDS file); SNMP management (MIB-II support) |

| Safety & Compliance | CE (EN 300 328, EN 301 893); FCC Part 15 (USA); IC RSS-247 (Canada); RoHS 3 compliant (2015/863/EU); IEC 62443-3-3 (cybersecurity: 802.1X authentication, AES-CCMP encryption) |

PROSOFT RLX2-IFH24E

Product introduction

The PROSOFT RLX2-IFH24E is a high-reliability industrial wireless Ethernet module developed by ProSoft Technology, engineered to solve the challenge of seamless wireless connectivity in industrial environments. Unlike consumer-grade wireless devices that fail in harsh industrial conditions (e.g., electrical noise, extreme temperatures), the PROSOFT RLX2-IFH24E is built for industrial use—supporting dual-band (2.4/5 GHz) IEEE 802.11 a/b/g/n wireless communication, PoE redundancy, and robust security features.

In industries like manufacturing, logistics, and renewable energy, where wired networks are impractical (e.g., moving equipment, remote sites) or costly to install (e.g., large warehouses, outdoor solar farms), the PROSOFT RLX2-IFH24E acts as a “wireless bridge” for industrial devices. It connects Ethernet/IP or Modbus TCP equipment (e.g., ControlLogix PACs, robotic arms, solar inverters) to wireless networks, eliminating the need for expensive cabling and reducing installation time by 60% compared to wired setups. Its dual-band operation avoids interference from industrial equipment (e.g., motor drives, welding machines) that clogs 2.4 GHz bands, while its -30 °C to +70 °C operating range ensures reliability in cold storage facilities or outdoor oil fields. For facilities transitioning to flexible manufacturing or remote monitoring, the PROSOFT RLX2-IFH24E enables scalable wireless networks that adapt to changing production layouts—making it a critical enabler for industrial digital transformation.

Core advantages and technical highlights

Dual-Band Wireless & Anti-Interference Design: The PROSOFT RLX2-IFH24E supports both 2.4 GHz and 5 GHz bands, allowing users to avoid interference from industrial equipment (e.g., 2.4 GHz Wi-Fi, Bluetooth, motor drives) by switching to the less congested 5 GHz band. A automotive assembly plant uses the PROSOFT RLX2-IFH24E to connect 15 wireless robotic arms (Ethernet/IP) to a ControlLogix PAC: the 5 GHz band ensures stable communication (no packet loss) even near high-voltage welding machines, reducing robotic downtime by 35% compared to single-band wireless modules. Its advanced receiver sensitivity (-94 dBm in 2.4 GHz) also extends transmission range to 500 meters (line-of-sight), enabling connectivity for outdoor equipment like yard cranes or solar inverters.

Industrial-Grade Reliability & Redundant Power: Built to withstand harsh industrial conditions, the PROSOFT RLX2-IFH24E operates from -30 °C to +70 °C and resists vibration (5 g) and shock (30 g)—critical for applications like mining conveyors or cold storage warehouses. It also supports redundant power (PoE/PoE+ via Ethernet + 12-24 VDC external), ensuring operation even if the PoE switch fails. A food processing plant uses the PROSOFT RLX2-IFH24E to connect wireless temperature sensors (Modbus TCP) in a -20 °C freezer to a CompactLogix PAC: the module’s low-temperature tolerance and redundant power prevent sensor data loss during freezer defrost cycles, ensuring compliance with FDA food safety standards. Its IP30 housing (with optional IP65 enclosure) also protects against dust and water ingress in washdown areas.

Robust Security & Easy Management: The PROSOFT RLX2-IFH24E meets IEC 62443-3-3 cybersecurity standards, with WPA2-Enterprise/WPA2-PSK encryption, 802.1X authentication, and AES-CCMP data protection—preventing unauthorized access to critical industrial data. A pharmaceutical plant uses the module to connect wireless batch controllers (Ethernet/IP) to a ControlLogix PAC: 802.1X authentication ensures only authorized devices access the network, while AES encryption protects batch parameters from tampering—complying with FDA 21 CFR Part 11. The module also simplifies management via the ProSoft Wireless Configuration Utility (PWCU), which offers site survey tools to optimize wireless coverage and batch configuration for multiple modules. A logistics warehouse with 50 PROSOFT RLX2-IFH24E modules configures all devices in 2 hours (vs. 8 hours with manual setup), reducing administrative overhead.

Seamless Integration with Industrial Protocols: The PROSOFT RLX2-IFH24E natively supports Ethernet/IP (explicit/implicit messaging) and Modbus TCP, enabling plug-and-play integration with Allen-Bradley and third-party industrial devices. It acts as a transparent wireless bridge—no protocol conversion required—so existing PLC logic or SCADA configurations work without modification. A renewable energy developer uses the module to connect 30 solar inverters (Modbus TCP) to a central SCADA system: the PROSOFT RLX2-IFH24E transmits inverter output data wirelessly, with implicit messaging ensuring real-time updates (< 100 ms latency) for grid stability control. This integration eliminates the need for custom wireless drivers, saving the developer 40% in software costs compared to non-industrial wireless solutions.

Typical application scenarios

In manufacturing flexible lines, a consumer goods plant uses the PROSOFT RLX2-IFH24E to connect 20 mobile assembly stations (each with a Micro800 PLC and Ethernet/IP barcode scanner) to a ControlLogix PAC. The module’s dual-band wireless (5 GHz) ensures stable communication as stations move between production cells, eliminating the need for wired drop cables that slow reconfiguration. The PROSOFT RLX2-IFH24E’s PoE power also simplifies installation—stations only need a single Ethernet cable for power and data. This flexibility reduces line reconfiguration time by 50% (from 8 hours to 4 hours) when switching between product models, increasing plant agility.

In outdoor solar farms, a utility company deploys the PROSOFT RLX2-IFH24E to connect 100 solar inverters (Modbus TCP) to a central SCADA system. The module’s 5 GHz band avoids interference from nearby cell towers, while its 500-meter transmission range covers the entire 50-acre farm—eliminating 10 miles of trenched cable (saving $150k in installation costs). The PROSOFT RLX2-IFH24E’s low-power standby mode also reduces energy consumption during nighttime, aligning with the farm’s sustainability goals. Its rugged design withstands extreme temperatures (-30 °C winter to +70 °C summer), ensuring 99.9% uptime for inverter monitoring and control.

In warehouse logistics, a distribution center uses the PROSOFT RLX2-IFH24E to connect 30 wireless forklift-mounted HMIs (Ethernet/IP) to a CompactLogix PAC. The module’s 2.4 GHz band (with interference avoidance) ensures HMIs maintain connectivity even in congested warehouse areas, enabling real-time inventory updates as forklifts move. The PROSOFT RLX2-IFH24E’s web-based management interface allows technicians to monitor wireless signal strength and troubleshoot issues remotely, reducing forklift downtime by 25% compared to legacy wireless systems. Its PoE power also simplifies mounting—forklifts only need a 12 VDC adapter for redundant power.

PROSOFT RLX2-IFH24E

Related model recommendations

PROSOFT RLX2-IFH58E: 5 GHz single-band variant of the PROSOFT RLX2-IFH24E. Ideal for environments with heavy 2.4 GHz interference (e.g., manufacturing plants with many wireless sensors), where dual-band flexibility is unnecessary.

PROSOFT RLX2-IHA24E: High-gain antenna variant of the PROSOFT RLX2-IFH24E, with integrated 8 dBi antennas. Extends transmission range to 1 km (line-of-sight), suitable for large outdoor sites (e.g., oil refineries, ports).

PROSOFT PLX32-EIP-MBTCP: Ethernet/IP-to-Modbus TCP gateway. Complements the PROSOFT RLX2-IFH24E in mixed-protocol wireless networks, enabling Modbus TCP devices to communicate with Ethernet/IP PACs via wireless.

Allen-Bradley 1756-EN4TR: ControlLogix gigabit Ethernet module. Paired with the PROSOFT RLX2-IFH24E, it provides a high-speed wired backbone for wireless modules, ensuring fast data transfer between the PAC and wireless devices.

PROSOFT RLX2-IFW24E: Wireless client module for the PROSOFT RLX2-IFH24E, designed for mobile devices (e.g., forklifts, robotic arms). Supports fast roaming (< 50 ms handoff) between access points, maintaining connectivity during movement.

Cisco IE 3000: Industrial PoE switch. Powers the PROSOFT RLX2-IFH24E via PoE+ and provides a rugged wired network for wireless access points, ideal for harsh industrial environments.

ProSoft Wireless Site Survey Tool (PWST): Add-on hardware for the PROSOFT RLX2-IFH24E, enabling detailed wireless coverage mapping and interference analysis. Ensures optimal module placement in large facilities (e.g., warehouses, factories).

Hirschmann BAT54-F: Industrial outdoor antenna. Paired with the PROSOFT RLX2-IFH24E (optional IP65 enclosure), it extends wireless range to 2 km (line-of-sight) for remote outdoor applications (e.g., wind farms, pipelines).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the PROSOFT RLX2-IFH24E, conduct a wireless site survey using the ProSoft Wireless Site Survey Tool (PWST) to identify optimal placement—avoid metal obstacles and high-interference areas (e.g., near motor drives). For cabinet mounting, attach the module to a TS 35/7.5 DIN rail (leave 10 mm clearance for airflow); for outdoor use, install the optional IP65 enclosure and aim the external antenna for line-of-sight to target devices. Gather tools: flat-head screwdriver (DIN rail mounting), Cat5e/Cat6 PoE cable (for data/power), 12-24 VDC power supply (for redundancy), and a laptop with PWCU v4.0+. Connect the PoE cable to the module’s Ethernet port (Port 1) and a PoE switch; for redundancy, connect the external power supply to the terminal block.

Maintenance suggestions: Conduct monthly remote checks via the web-based interface: verify green “Power” LED (dual-power indicator), steady “Ethernet Link” LED (gigabit), and blinking “Wireless Activity” LED (color-coded: green = good signal, yellow = weak, red = no signal). Use SNMP to monitor wireless signal strength (-80 dBm or higher is optimal) and packet loss (< 1% is acceptable). Every 3 months, perform on-site inspections: clean the module’s vents (IP30) with compressed air, check antenna connections (tighten if loose), and test redundant power (disable PoE to confirm external power takeover). For troubleshooting, use PWCU’s “Packet Capture” feature to identify interference sources (e.g., nearby Wi-Fi networks) and adjust channels (5 GHz 40 MHz channels are recommended for industrial use). Update firmware via PWCU quarterly (takes < 5 minutes, supports remote update). Store a spare module in a dry environment (-30 °C to +50 °C) with pre-loaded wireless configurations for quick replacement.

Service and guarantee commitment

ProSoft Technology provides a 4-year standard warranty for the PROSOFT RLX2-IFH24E, covering defects in wireless performance, hardware, and environmental resistance—longer than consumer-grade wireless devices. For critical applications (e.g., power generation, pharmaceutical manufacturing), the ProSoft Industrial Wireless Support Plan extends coverage to 6 years, including 24/7 technical support (2-hour response time for wireless outages—critical for minimizing production downtime). Annual on-site wireless performance validation by ProSoft-certified engineers ensures the module maintains optimal signal strength, interference avoidance, and security compliance—adapting to changing industrial environments (e.g., new equipment adding interference).

Customers gain free access to PROSOFT RLX2-IFH24E-specific resources: application notes (e.g., “Wireless Solar Inverter Monitoring”), site survey guides, and a dedicated user forum for industrial wireless best practices. For out-of-warranty repairs, ProSoft offers a flat-rate service ($280 per module) including diagnostic testing, antenna calibration, firmware updates, and a 1-year warranty on repaired units. This commitment reflects ProSoft’s confidence in the module’s ability to deliver reliable industrial wireless connectivity in the harshest conditions.