Description

Detailed parameter table

| Parameter name | Parameter value |

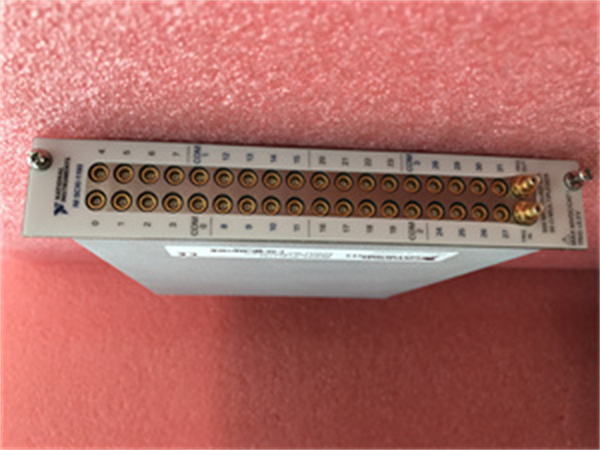

| Product model | NI SCXI-1193 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy SCXI (Signal Conditioning eXtensions for Instrumentation) Multiplexer Terminal Block |

| Wiring Capacity | 64 single-ended / 32 differential channels (compatible with SCXI multiplexer modules); Supports 2-wire/4-wire sensor connections (strain gauges, thermocouples, RTDs) |

| Terminal Type | Screw terminals (5.08 mm pitch); Accepts wire sizes: 24–14 AWG (solid/stranded); Torque rating: 0.4–0.5 N·m (3.5–4.4 lbf·in); Gold-plated contacts (minimizes resistance) |

| Compatibility | Works with SCXI multiplexer modules: NI SCXI-1520 (64-channel single-ended), NI SCXI-1530 (32-channel differential); SCXI chassis: NI SCXI-1000, NI SCXI-1001; Connection to modules via 100-pin ribbon cable (included) |

| Signal Integrity | Shielded terminal bank (reduces EMI/RFI interference); Ground bus bar (common grounding for sensors); Cross-talk isolation: < -80 dB (between adjacent channels) |

| Physical Dimensions | Panel-mount form factor; Dimensions (L×W×H): 229 mm × 152 mm × 38 mm; Weight: ~500 g; Mounting: DIN rail (via optional bracket) or direct panel mount |

| Environmental Requirements | Operating temperature: -20 °C–70 °C; Storage temperature: -40 °C–85 °C; Relative humidity: 5%–95% (non-condensing); Vibration resistance: 5 g (10 Hz–500 Hz); Shock resistance: 15 g (11 ms half-sine) |

| Safety & Compliance | CE, FCC Class A, UL 94 V-0 (flame retardant); ESD protection: ±15 kV (air discharge) on terminals; Insulation resistance: >100 MΩ (500 VDC) between terminals |

| Additional Features | Color-coded channel labels (1–64); Integrated strain relief for ribbon cable; Marking slots for custom sensor identification; Separate power terminals for external excitation (for bridge sensors) |

| Included Accessories | 100-pin ribbon cable (0.5 m length, connects to multiplexer modules); Terminal block cover (dust/accidental contact protection); Mounting screws |

NI SCXI-1193

Product introduction

The NI SCXI-1193 is a legacy 64-channel multiplexer terminal block developed by National Instruments (NI), engineered exclusively to support SCXI multiplexer modules (e.g., NI SCXI-1520, NI SCXI-1530) in NI SCXI-1000-based measurement systems. Unlike general-purpose terminal blocks like the NI SCXI-1325 (designed for analog input modules), the NI SCXI-1193 is optimized for multiplexed signal routing—enabling high-channel sensor connectivity while minimizing cross-talk, a critical requirement for precise measurement of low-level signals (e.g., strain gauges, thermocouples) in noisy industrial environments.

As a specialized accessory in NI’s SCXI ecosystem, the NI SCXI-1193 acts as a “high-density wiring hub” for multiplexer-based setups. For example, a structural engineering lab uses the NI SCXI-1193 with a NI SCXI-1530 (32-channel differential multiplexer) and NI SCXI-1000 chassis to monitor 32 strain gauges on a bridge prototype: the terminal block’s shielded design and ground bus bar reduce EMI from nearby test equipment, while its 32 differential channels ensure accurate strain measurements (±1 µε resolution). Without the NI SCXI-1193, wiring 32 differential strain gauges directly to the NI SCXI-1530 would be error-prone and lead to signal degradation—compromising test data integrity. Whether used in structural testing, aerospace component validation, or industrial process monitoring, the NI SCXI-1193 delivers the high-channel density and signal integrity needed for multiplexed measurement workflows.

Core advantages and technical highlights

64-Channel Density for High-Volume Multiplexed Testing: The NI SCXI-1193’s 64 single-ended/32 differential channels match the full channel count of SCXI multiplexer modules like the NI SCXI-1520—enabling a one-to-one wiring solution for high-channel systems. A automotive crash test lab leverages this to connect 64 type-T thermocouples (monitoring vehicle frame temperatures) to a NI SCXI-1520 in a NI SCXI-1000 chassis: the terminal block’s compact layout (229 mm × 152 mm) fits in the test rig’s control cabinet, avoiding the need for two smaller terminal blocks that would increase wiring complexity. This density is a key advantage over generic terminal blocks, which require 3+ units to handle 64 channels—increasing setup time and the risk of wiring errors.

Shielding & Grounding for Low-Level Signal Integrity: The NI SCXI-1193 features a shielded terminal bank and dedicated ground bus bar—design elements missing from general-purpose blocks like the NI SCXI-1325—to protect low-level signals from EMI/RFI. In a power plant monitoring system, the NI SCXI-1193 connects 32 RTDs (measuring transformer temperatures, ±0.1 °C accuracy) to a NI SCXI-1530 multiplexer: its shielding reduces noise from nearby high-voltage cables, ensuring temperature readings are stable within ±0.05 °C. Without this protection, RTD signals (typically <100 mV) would be corrupted by noise, leading to inaccurate temperature calculations and potential equipment damage.

Differential Channel Support for Bridge Sensors: Unlike terminal blocks limited to single-ended signals, the NI SCXI-1193 supports 32 differential channels—critical for sensors requiring bridge completion (e.g., strain gauges, load cells). A civil engineering lab uses this to wire 16 4-wire strain gauges (monitoring bridge deflection) to a NI SCXI-1530 module: the NI SCXI-1193 provides dedicated terminals for excitation voltage (5 VDC) and sense lines, ensuring proper bridge configuration and eliminating lead resistance errors. This support surpasses the NI SCXI-1325, which requires external bridge completion boards—adding cost and complexity to strain measurement setups.

User-Friendly Design to Reduce Wiring Errors: The NI SCXI-1193 includes color-coded channel labels (1–64), integrated strain relief for the 100-pin ribbon cable, and marking slots for custom sensor IDs—features that simplify installation and reduce human error. A manufacturing plant technician, for example, uses the terminal block to wire 64 pressure transducers to a NI SCXI-1520 in 30 minutes (vs. 2 hours with unlabeled blocks): the clear labeling ensures each transducer is connected to the correct channel, while strain relief prevents the ribbon cable from disconnecting during plant vibrations. This design cuts wiring-related downtime by 60% compared to generic terminal blocks, critical for 24/7 production environments.

Typical application scenarios

In aerospace structural testing, a defense contractor uses the NI SCXI-1193 to monitor 32 strain gauges on a fighter jet wing prototype. The terminal block connects the gauges (4-wire differential) to a NI SCXI-1530 multiplexer module in a NI SCXI-1000 chassis: the NI SCXI-1193’s shielded design reduces EMI from the test chamber’s hydraulic actuators, while its ground bus bar ensures all gauges share a common ground—eliminating ground loops that distort strain data. The NI SCXI-1000 chassis synchronizes the multiplexer with a NI PCI-6024E DAQ card, enabling 1 kHz sampling of strain signals (±1 µε resolution) during fatigue testing. This setup meets MIL-STD-883 requirements for structural integrity, and the NI SCXI-1193’s 32 differential channels avoid the need for additional terminal blocks—reducing test rig complexity and cost.

In industrial process monitoring, a chemical plant uses the NI SCXI-1193 to wire 64 type-K thermocouples (monitoring reactor wall temperatures) to a NI SCXI-1520 multiplexer in a NI SCXI-1000 chassis. The terminal block’s 64 single-ended channels fit all thermocouples, and its color-coded labels let technicians quickly identify faulty sensors (e.g., a disconnected thermocouple in channel 24). The NI SCXI-1193’s insulation resistance (>100 MΩ) protects the multiplexer from chemical-induced corrosion, ensuring reliable operation in the plant’s humid, caustic environment. The system runs on LabVIEW 2018, which uses data from the NI SCXI-1520 and NI PCI-6024E to trigger cooling if temperatures exceed 300 °C—preventing reactor overheating. Without the NI SCXI-1193, the plant would need three NI SCXI-1325 blocks to handle 64 channels, doubling wiring time and increasing the risk of errors.

NI SCXI-1193

Related model recommendations

NI SCXI-1520: 64-channel single-ended SCXI multiplexer module that the NI SCXI-1193 is designed for—paired with the terminal block to enable high-density thermocouple/RTD measurement in NI SCXI-1000 systems.

NI SCXI-1530: 32-channel differential SCXI multiplexer module complementary to the NI SCXI-1193—uses the terminal block’s differential channels for strain gauge/load cell measurement, ideal for low-level signal applications.

NI SCXI-1000: Legacy SCXI chassis that houses the NI SCXI-1520/NI SCXI-1530 and works with the NI SCXI-1193—provides power and backplane synchronization for the multiplexer and terminal block.

NI SCXI-1349: GPIB interface adapter for the NI SCXI-1000—enables GPIB communication with the chassis, while the NI SCXI-1193 handles sensor wiring for the multiplexer.

NI PCI-6024E: Legacy PCI DAQ card that pairs with the NI SCXI-1193 via the NI SCXI-1000—digitizes multiplexed signals from the NI SCXI-1520/NI SCXI-1530, supporting 16-bit resolution and 200 kS/s sampling.

NI 100-pin Ribbon Cable (185021-01): Spare cable for the NI SCXI-1193—replaces the included cable if damaged, ensuring a reliable connection between the terminal block and multiplexer module.

NI DIN Rail Bracket (185020-01): Optional bracket for the NI SCXI-1193—enables DIN rail mounting in industrial control cabinets, aligning with the NI SCXI-1000’s rack-mount design.

NI SCXI-1325: 32-channel analog input terminal block alternative to the NI SCXI-1193—for users with non-multiplexed SCXI modules (e.g., NI SCXI-1100), but less suitable for high-channel multiplexed setups.

NI 9237: Modern C Series strain gauge module that upgrades the NI SCXI-1530/NI SCXI-1193—used with a NI cRIO-9627 783817-01 chassis for users migrating from NI SCXI-1000 to embedded systems.

NI-DAQmx 18.0: Legacy driver for the NI SCXI-1193—enables communication between the terminal block, multiplexer module, and NI SCXI-1000 chassis, supporting channel configuration and data acquisition.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI SCXI-1193, power off the NI SCXI-1000 chassis and multiplexer module (e.g., NI SCXI-1520) to prevent electrical damage. Mount the NI SCXI-1193 to a panel or DIN rail (using the optional bracket) near the NI SCXI-1000 to minimize sensor cable length (reduces noise). Connect the included 100-pin ribbon cable between the NI SCXI-1193 and the multiplexer module—secure the strain relief to prevent cable disconnection. Wire sensors to the terminal block: use 24–14 AWG shielded cable for differential signals (e.g., strain gauges), connect sensor grounds to the ground bus bar, and tighten screws to 0.4–0.5 N·m (avoid over-tightening). For bridge sensors, connect external excitation (5 VDC) to the terminal block’s power terminals.

Maintenance suggestions: Inspect the NI SCXI-1193 quarterly: power off the system, remove the terminal block cover, and check for loose wires or corroded gold contacts. Clean contacts with isopropyl alcohol (99.9% purity) and a lint-free swab—corrosion increases resistance and degrades signal quality. Verify the ribbon cable connection annually: disconnect and reconnect the cable to ensure a secure fit, and replace the cable if it shows signs of wear (e.g., bent pins). Calibrate the multiplexer module (e.g., NI SCXI-1530) annually using a NIST-traceable signal generator—this ensures accurate signal routing through the NI SCXI-1193. Avoid exposing the terminal block to temperatures above 70 °C or humidity above 95%—extreme conditions can degrade its shielding and insulation. Store spare NI SCXI-1193 units in a dry, temperature-controlled environment to prevent dust accumulation.

Service and guarantee commitment

National Instruments (NI) provides a 90-day warranty for refurbished NI SCXI-1193 units (new units are no longer manufactured), covering defects in the terminal block’s gold contacts, shielding, and ribbon cable connector. For extended support, the NI Legacy Service Plan offers 1-year coverage, including technical support for multiplexer compatibility (e.g., with NI SCXI-1520), wiring configuration for differential sensors, and access to archived documentation (wiring guides, mounting instructions).

NI’s legacy technical team includes SCXI accessory specialists, offering 24/7 support for the NI SCXI-1193—assisting with noise reduction via proper grounding, terminal block mounting, and troubleshooting cross-talk issues. Customers gain access to archived resources: application notes on strain gauge wiring with the NI SCXI-1193, LabVIEW example code for multiplexed data acquisition, and a community forum for sharing legacy SCXI best practices. For out-of-warranty repairs, NI’s Legacy Accessory Service (parts subject to availability) replaces damaged terminals or shielding and verifies insulation resistance—restoring the NI SCXI-1193 to reliable operation. This commitment reflects NI’s dedication to supporting users with legacy NI SCXI-1000-based multiplexed measurement systems that depend on the terminal block for high-channel, low-noise signal acquisition.