Description

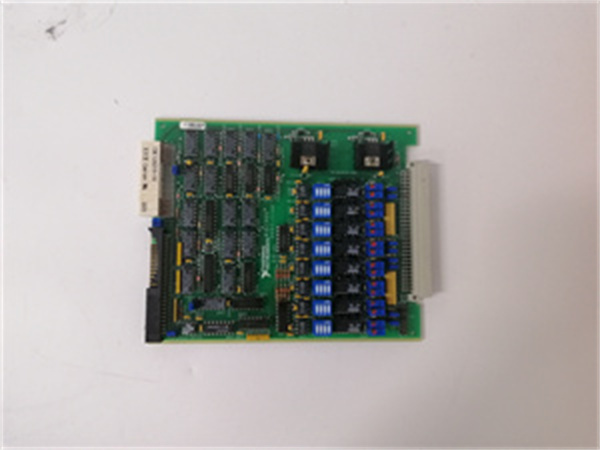

NI SCXI-1140 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SCXI-1140 |

| Manufacturer | National Instruments |

| Product Category | Thermocouple Signal Conditioning Module |

| Channel Count | 16 differential thermocouple channels |

| Supported Thermocouple Types | J, K, T, E, R, S, B, N |

| Temperature Measurement Range | Dependent on thermocouple type (e.g., K-type: -270°C to 1372°C) |

| Cold-Junction Compensation | Built-in, with accuracy of ±0.5°C (0°C to 55°C) |

| Measurement Resolution | 0.1°C (typical) |

| Linearization | Polynomial linearization for all thermocouple types |

| Filtering | 50 Hz/60 Hz notch filter (software-selectable) and 3-pole low-pass filter (1 Hz) |

| Excitation | Not required (thermocouple self-generating) |

| Isolation | 250 Vrms channel-to-chassis isolation |

| CMRR | >100 dB at DC |

| Dimensions | Designed for SCXI chassis (fits 3U SCXI slots) |

| Operating Temperature Range | 0°C to 55°C |

| Relative Humidity | 10% to 90% non-condensing |

| Power Consumption | Derived from SCXI chassis (typically 1.5 W) |

| Calibration | Factory-calibrated; calibration constants stored in non-volatile memory |

| Software Compatibility | NI-DAQmx, LabVIEW, LabWindows/CVI, C/C++, .NET |

NI SCXI-1140

Product Introduction

The NI SCXI-1140 is a specialized thermocouple signal conditioning module designed to accurately measure temperature using various thermocouple types. As a key component of the SCXI ecosystem, it integrates seamlessly with SCXI chassis like the SCXI-1001, providing precise signal conditioning for thermocouple inputs in industrial, research, and laboratory environments.

This module addresses the unique challenges of thermocouple measurements, including cold-junction compensation, signal amplification, and noise filtering. With 16 differential channels, it enables simultaneous temperature monitoring across multiple points, making it ideal for applications requiring distributed temperature sensing. Whether used in furnace monitoring, environmental chambers, or material testing, the SCXI-1140 delivers reliable and accurate temperature data by conditioning weak thermocouple signals (typically microvolts) into robust signals suitable for DAQ devices.

Core Advantages and Technical Highlights

Comprehensive Thermocouple Support

The SCXI-1140 supports all common thermocouple types (J, K, T, E, R, S, B, N), eliminating the need for multiple modules when working with different thermocouple types in a single system. This versatility is particularly valuable in research facilities or manufacturing plants where diverse temperature measurement requirements exist—for example, using K-type thermocouples for high-temperature furnace monitoring and T-type for cryogenic applications.

Precision Cold-Junction Compensation

Thermocouples require cold-junction compensation to account for ambient temperature at the measurement junction. The SCXI-1140 features built-in cold-junction compensation with ±0.5°C accuracy (over 0°C to 55°C), ensuring precise temperature measurements even as ambient conditions fluctuate. This eliminates the need for external compensation circuits and reduces measurement errors in dynamic environments, such as industrial ovens with varying room temperatures.

Advanced Noise Filtering

Thermocouple signals are inherently weak (microvolts), making them susceptible to electromagnetic interference (EMI) and line noise. The SCXI-1140 incorporates dual filtering: a software-selectable 50 Hz/60 Hz notch filter to eliminate power line noise, and a 3-pole low-pass filter (1 Hz) to suppress high-frequency interference. This combination ensures clean, stable signals—critical for accurate temperature measurements in noisy industrial settings, such as near motors or power distribution panels.

Channel Isolation and CMRR

With 250 Vrms channel-to-chassis isolation and >100 dB CMRR (common-mode rejection ratio) at DC, the SCXI-1140 minimizes ground loops and common-mode noise—common issues in multi-channel temperature systems. This isolation protects sensitive DAQ equipment from voltage transients and ensures measurement integrity when monitoring temperatures across electrically isolated components, such as in power electronics or HVAC systems with multiple zones.

Typical Application Scenarios

Industrial Furnace Monitoring

In metal processing or ceramic manufacturing, the SCXI-1140 monitors temperature profiles across industrial furnaces using K-type thermocouples. Its 16 channels track temperatures at different zones within the furnace, ensuring uniform heating and preventing overheating of sensitive materials. The module’s filtering capabilities reject noise from furnace motors and heating elements, while cold-junction compensation accounts for temperature variations at the thermocouple connection points.

Environmental Chamber Testing

Environmental chambers used for product reliability testing (e.g., electronics, automotive components) require precise temperature monitoring. The SCXI-1140, paired with a SCXI-1001 chassis and DAQ device, measures temperatures at multiple points within the chamber using T-type thermocouples. It captures temperature cycles (e.g., -40°C to 85°C) with 0.1°C resolution, enabling engineers to validate product performance under extreme conditions.

Building Automation Systems

In large commercial buildings, the SCXI-1140 monitors HVAC system temperatures across multiple zones. It uses E-type thermocouples to measure air intake, duct, and room temperatures, providing data to the building management system for efficient climate control. The module’s isolation and CMRR ensure accurate measurements even in environments with electrical noise from lighting or machinery.

NI SCXI-1140

Material Testing

In materials science research, the SCXI-1140 measures temperature during material stress tests (e.g., tensile testing under thermal load). It uses R-type thermocouples for high-precision measurements of metal samples heated to extreme temperatures, capturing thermal expansion or phase change data. The module’s linearization feature ensures accurate conversion of thermocouple voltage to temperature, critical for research-grade results.

Related Model Recommendations

NI SCXI-1001 Chassis: Houses the SCXI-1140 and up to 11 other SCXI modules, providing power, timing, and signal routing. Its compact design is ideal for rack-mounted or portable temperature monitoring systems.

NI USB-6211 DAQ Device: Acquires conditioned signals from the SCXI-1140, converting analog temperature data to digital for analysis. Compatible with NI-DAQmx for seamless integration.

NI 9211 C Series Module: A complementary thermocouple module for mixed systems requiring both SCXI and CompactDAQ platforms. Useful for expanding channel count in distributed temperature monitoring.

NI LabVIEW: Enables custom temperature monitoring applications with real-time data visualization, alarm triggering, and data logging. Integrates with SCXI-1140 via NI-DAQmx for automated test sequences.

Thermocouple Extension Cables: Shielded, thermocouple-type-matched cables (e.g., K-type extension wires) to connect thermocouples to the SCXI-1140, minimizing measurement errors from lead resistance.

Installation, Commissioning, and Maintenance

Installation Steps

Module Insertion: Power off the SCXI chassis (e.g., SCXI-1001). Insert the SCXI-1140 into an available slot, ensuring it seats fully in the backplane. Secure with front-panel screws to prevent movement.

Thermocouple Connection: Connect thermocouples to the module’s terminal block using color-coded leads (per thermocouple type standards). Use twisted-pair, shielded cables and ground the shield at the chassis end to reduce noise.

DAQ Integration: Connect the SCXI chassis to a DAQ device (e.g., USB-6211) via the chassis’ output connector. Power on the chassis and verify module detection using NI Measurement & Automation Explorer (MAX).

Commissioning

Configuration: Use MAX to configure thermocouple types for each channel, enable/disable filters, and set cold-junction compensation parameters. Calibrate cold-junction sensors if operating outside 0°C to 55°C.

Accuracy Verification: Test with a calibrated temperature source (e.g., dry-block calibrator) at 3-5 points across the thermocouple range. Verify measurements are within the module’s specified accuracy (±0.5°C for cold junction + thermocouple error).

Noise Testing: Introduce a known noise source (e.g., nearby motor) and confirm the notch filter suppresses 50/60 Hz noise. Measure signal stability over 1 hour to ensure no drift.

Maintenance Tips

Terminal Inspection: Periodically check thermocouple connections for corrosion or looseness, which can introduce measurement errors. Clean terminals with a soft brush and ensure proper torque when reconnecting.

Cold-Junction Calibration: Re-calibrate cold-junction sensors annually using a precision thermometer. This is critical for applications requiring high accuracy, such as pharmaceutical manufacturing.

Filter Verification: Test filter functionality yearly by applying a 50 Hz/60 Hz signal and confirming >40 dB attenuation. Replace the module if filtering performance degrades.

Environmental Protection: Operate within 0°C to 55°C and avoid exposure to condensation, which can damage isolation components. Use conformal coating for modules in humid environments.

Service and Guarantee Commitment

The NI SCXI-1140 includes a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ technical support provides 24/7 assistance for configuration, troubleshooting, and calibration via phone, email, and online resources.

NI offers accredited calibration services with NIST-traceable certificates, ensuring compliance with ISO 9001 and FDA regulations for critical applications. Extended warranty plans and repair services are available to extend the module’s lifespan. Backed by NI’s expertise in temperature measurement, the SCXI-1140 delivers reliable performance for demanding thermocouple applications.