Description

NI SCXI-1001 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

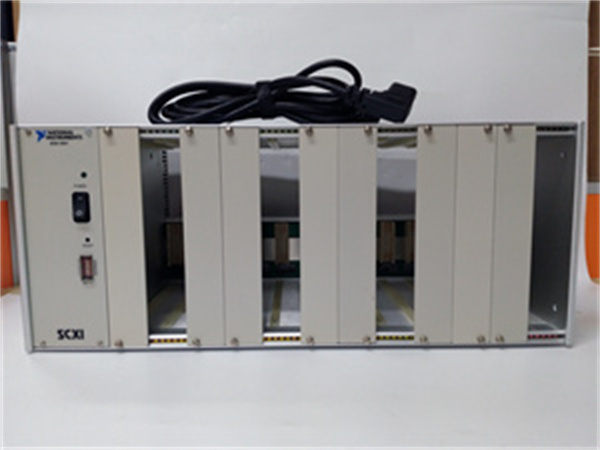

| Product Model | SCXI-1001 |

| Manufacturer | National Instruments |

| Product Category | Signal Conditioning Chassis |

| Form Factor | Compact, suitable for rack – mount, panel mount, and portable setups |

| Slot Capacity | 12 slots for SCXI modules |

| Input Voltage Range | ±10 V (for modules installed; varies by module type) |

| Resolution | 16 bits (dependent on module; typical for many SCXI modules) |

| Input Channels | Up to 64 differential or 128 single – ended (varies based on module configuration) |

| Input Impedance | 1 MΩ |

| Output Channels | Up to 64 (again, module – dependent) |

| Output Voltage Range | ±10 V (module – specific) |

| Output Impedance | 100 Ω (module – related) |

| Analog Bandwidth | DC to 200 kHz (common range for many SCXI – 1001 – compatible modules) |

| Digital I/O | 8 bidirectional lines |

| Dimensions | 211 mm (width) x 43 mm (height) x 219 mm (depth) |

| Weight | 1.1 kg |

| Operating Temperature Range | 0 °C to 55 °C |

| Relative Humidity | 10% to 90%, non – condensing |

| Power Requirements | 5 VDC, 2.5 A |

| Tariff Code | 8537109070 |

| Country of Origin | United States |

| Software Compatibility | NI – DAQ software for simplified configuration and measurements |

NI SCXI-1001

Product Introduction

The NI SCXI – 1001 is a rugged and compact signal conditioning chassis designed to be the backbone of data acquisition systems. With the capacity to house up to 12 SCXI modules, it offers a highly flexible platform for a wide range of applications. It serves as a central hub that not only powers the SCXI modules but also manages all the crucial aspects of timing, triggering, and signal routing between the digitizer and the modules.

This chassis is an ideal choice for those looking to build or expand a data acquisition system. Its design allows for easy integration into different setups, whether it’s a rack – mounted industrial monitoring system, a panel – mounted test bench, or a portable data logging solution. For high – channel – count applications, up to eight SCXI – 1001 chassis can be daisy – chained together using a single E – series digitizer, providing scalability for future expansion.

Core Advantages and Technical Highlights

Modular and Scalable Design

The 12 – slot configuration of the SCXI – 1001 enables users to mix and match different SCXI modules according to their specific measurement needs. For example, one can combine a module for strain gauge measurement with another for thermocouple input. This modularity allows for a highly customized data acquisition system, which can be easily reconfigured as requirements change. The ability to daisy – chain multiple chassis further enhances its scalability, making it suitable for large – scale projects where a high number of channels are required.

Low – Noise Signal Conditioning Environment

The SCXI – 1001 is engineered to provide a low – noise environment for signal conditioning. This is crucial for applications where precision measurements are required, such as in scientific research or high – accuracy industrial sensing. By minimizing electrical interference, it ensures that the signals being conditioned and measured are as accurate as possible. The chassis design includes features to shield against external electromagnetic fields, maintaining the integrity of the signals passing through the modules.

Timing Circuitry for High – Speed Multiplexing

Equipped with advanced timing circuitry, the SCXI – 1001 is well – suited for high – speed multiplexing applications. When multiple channels need to be sampled rapidly, the precise timing control ensures that each channel is sampled at the correct intervals. This is particularly important in applications like high – speed data logging or real – time process monitoring, where accurate timing of data acquisition can make a significant difference in the quality of the data collected.

Simplified Configuration with NI – DAQ Software

The NI – DAQ driver simplifies the configuration and measurement process. With this software, users can easily set up the parameters for each SCXI module installed in the chassis. For instance, one can quickly configure the input range, sampling rate, and channel routing directly from the NI – DAQ interface. This user – friendly software interface reduces the complexity of setting up a data acquisition system, making it accessible to both experienced engineers and those new to data acquisition.

Typical Application Scenarios

Sensor Signal Conditioning

In industrial settings, various sensors such as pressure sensors, temperature sensors, and vibration sensors produce signals that need to be conditioned before being processed. The SCXI – 1001, with its appropriate SCXI modules, can amplify, filter, and convert these sensor signals into a format suitable for data acquisition. For example, in a manufacturing plant, a SCXI module in the SCXI – 1001 chassis can condition the output of a vibration sensor on a critical piece of machinery, providing valuable data for predictive maintenance.

Data Logging

The SCXI – 1001 is an excellent choice for long – term data logging applications. It can be set up to continuously record data from multiple sensors over an extended period. In environmental monitoring, for instance, it can be used to log temperature, humidity, and air quality data. The chassis, along with its associated modules, can be configured to sample the sensor data at regular intervals and store it for later analysis. This data can then be used to identify trends, detect anomalies, or comply with regulatory requirements.

Process Monitoring and Control

In industrial processes, real – time monitoring and control are essential. The SCXI – 1001 can be integrated into a process control system to monitor critical parameters such as flow rates, pressures, and temperatures. By using appropriate SCXI modules, it can not only measure these parameters but also provide feedback for control purposes. For example, in a chemical plant, the SCXI – 1001 can monitor the temperature of a reaction vessel and send signals to a control system to adjust the heating or cooling process as needed.

Industrial Measurements

In industrial measurement applications, accuracy and reliability are key. The SCXI – 1001, with its low – noise environment and modular design, can be used for a variety of measurements. It can measure electrical parameters such as voltage, current, and resistance, as well as physical parameters like force, displacement, and acceleration. In a power generation plant, it can be used to measure the electrical output of generators accurately, ensuring efficient operation and proper maintenance.

NI SCXI-1001

Related Model Recommendations

NI E – series Digitizers: These digitizers work seamlessly with the SCXI – 1001, especially when daisy – chaining multiple chassis. For example, the NI USB – 6211 can be used as a digitizer to acquire data from the SCXI – 1001 chassis, providing high – speed and accurate data conversion.

SCXI Modules: There are a wide range of SCXI modules available that can be installed in the SCXI – 1001. For sensor signal conditioning, the SCXI – 1125 is a great choice for measuring strain gauges. The SCXI – 1141 can be used for thermocouple measurements, and the SCXI – 1161 is suitable for high – voltage measurements.

NI – DAQmx Software: In addition to the basic NI – DAQ software, NI – DAQmx offers more advanced features for data acquisition and system configuration. It provides a more comprehensive set of functions for tasks such as multi – channel data acquisition, complex triggering, and high – speed streaming.

Installation, Commissioning, and Maintenance

Installation Steps

Chassis Mounting: The SCXI – 1001 can be mounted in a 19 – inch rack using the appropriate rack – mounting kit. For panel – mount applications, it can be installed in a custom – designed panel. In portable setups, it can be placed in a suitable carrying case. Ensure that the mounting location is stable and well – ventilated.

Module Insertion: Power off the chassis before inserting SCXI modules. Gently slide the modules into the available slots, ensuring that they are properly aligned and seated. Secure the modules in place using the provided locking mechanisms.

Cabling: Connect the sensors or other input sources to the appropriate SCXI modules. Use shielded cables to minimize noise interference. Connect the output of the chassis to the digitizer or data acquisition system using the recommended cables.

Power Connection: Connect the power supply to the SCXI – 1001, ensuring that the voltage and current requirements are met. The power supply should be a stable 5 VDC source capable of providing 2.5 A.

Commissioning

Software Installation and Configuration: Install the NI – DAQ software on the host computer. Use the software to detect the SCXI – 1001 chassis and the installed modules. Configure the parameters for each module, such as input range, sampling rate, and channel type.

Functionality Testing: Perform basic functionality tests on each module. For example, if a thermocouple module is installed, apply a known temperature source and verify that the measured temperature value is accurate. Use a multimeter or other reference instruments to validate the measurements.

Timing and Synchronization: Check the timing and synchronization of the chassis, especially if multiple channels are being used. Ensure that the sampling intervals are correct and that the data from different channels is properly synchronized.

Maintenance Tips

Regular Inspection: Periodically inspect the chassis and the installed modules for any signs of physical damage, loose connections, or overheating. Check the terminal blocks for corrosion or discoloration, which could indicate a problem with the electrical connections.

Cleaning: Keep the chassis and modules clean to prevent dust and debris from accumulating, which could affect the performance. Use a soft, dry cloth to clean the exterior of the chassis and modules. Avoid using harsh chemicals that could damage the components.

Calibration: Calibrate the SCXI modules regularly, especially if high – accuracy measurements are required. Follow the calibration procedures provided by National Instruments, which may involve using reference standards and the NI – DAQ software.

Firmware Updates: Stay updated with the latest firmware versions for the SCXI – 1001 and the installed modules. Firmware updates often include bug fixes, performance improvements, and new features. Check the National Instruments website regularly for available updates.

Service and Guarantee Commitment

The NI SCXI – 1001 comes with a standard warranty that covers defects in materials and workmanship. National Instruments also offers repair services for the chassis and the SCXI modules. In case of any issues, users can contact the National Instruments technical support team, which provides assistance in troubleshooting, installation, and configuration.

The company also provides calibration services to ensure the accuracy of the data acquisition system. Calibration certificates are available, which are traceable to national or international standards. This commitment to service and support ensures that the SCXI – 1001 continues to perform reliably throughout its lifespan, providing users with a long – term solution for their data acquisition and signal conditioning needs.