Description

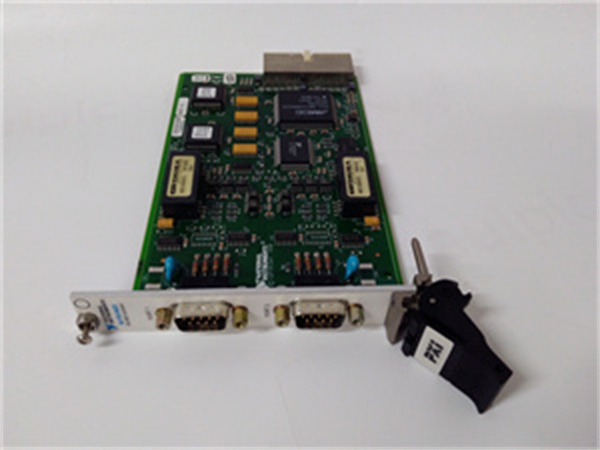

NI PXI-8423 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXI-8423 |

| Manufacturer | National Instruments |

| Product Category | PXI Serial Communication Module |

| Form Factor | 3U PXI |

| Slot Requirement | 1 PXI slot |

| Serial Ports | 4 RS-232 ports |

| Data Transfer Rates | Up to 921.6 kbps |

| Interface Standards | RS-232 (EIA/TIA-232-F) |

| Connector Type | 4 x DB-9 (female) |

| Buffer Size | 4 kB transmit and receive buffers per port |

| Flow Control | Hardware (RTS/CTS, DTR/DSR) and software (XON/XOFF) |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 100 mm (width) x 160 mm (depth) x 37 mm (height) |

| Weight | 300 g |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Software Compatibility | LabVIEW, LabWindows/CVI, .NET, C/C++, NI-VISA |

NI PXI-8423

Product Introduction

The NI PXI-8423 is a 3U PXI serial communication module designed to enable reliable RS-232 connectivity in automated test and measurement systems, industrial control setups, and embedded applications. With 4 independent RS-232 ports, it provides flexible serial communication for interfacing with a wide range of devices such as sensors, actuators, programmable logic controllers (PLCs), and legacy instruments that use serial protocols.

This module integrates seamlessly with PXI chassis like the PXI-1031 and works in conjunction with controllers such as the PXI-8186, enabling centralized management of serial communication tasks within a PXI system. Its high data transfer rates and robust buffering capabilities make it suitable for applications requiring efficient serial data exchange, from simple command/response interactions to continuous data streaming. Whether deployed in manufacturing test stations, industrial automation lines, or research laboratories, the PXI-8423 delivers stable and efficient serial communication.

Core Advantages and Technical Highlights

Multi-Port Serial Connectivity

With 4 independent RS-232 ports, the PXI-8423 allows simultaneous communication with multiple serial devices, eliminating the need for multiple single-port modules. This is particularly valuable in systems where several devices (e.g., a temperature sensor, a motor controller, and a barcode scanner) need to be monitored or controlled via serial protocols. Each port operates independently, with its own buffers and configuration settings, ensuring interference-free communication.

High-Speed Data Transfer

Supporting data rates up to 921.6 kbps, the PXI-8423 facilitates fast serial communication, making it suitable for applications that require rapid data exchange. For example, in a production line test system, it can quickly receive test results from a serial-equipped DUT (device under test) or send configuration commands to a programmable instrument, reducing overall test cycle time.

Robust Buffering and Flow Control

Each port on the PXI-8423 features 4 kB transmit and receive buffers, which help prevent data loss during high-speed or bursty communication. The module also supports both hardware (RTS/CTS, DTR/DSR) and software (XON/XOFF) flow control, allowing it to adapt to different device requirements. Hardware flow control is particularly useful for high-speed communication, where it can quickly pause data transmission to prevent buffer overflow, while software flow control is ideal for simpler devices with limited hardware capabilities.

Seamless Integration with PXI Systems

As a PXI module, the PXI-8423 leverages the PXI bus for communication with the system controller (e.g., PXI-8186), ensuring low-latency data transfer and easy integration into larger PXI systems. It is recognized automatically by NI software tools like Measurement & Automation Explorer (MAX), simplifying configuration and setup. This integration allows serial communication tasks to be synchronized with other system operations, such as data acquisition from the PXI-4462 or digital control via the PXI-6527.

Typical Application Scenarios

Industrial Automation and Control

In industrial settings, the PXI-8423 serves as a communication hub for connecting PXI control systems with serial-equipped industrial devices. For example, it can communicate with PLCs to exchange process data, send commands to motor drives via RS-232, or receive status updates from temperature controllers. When paired with the PXI-8186 controller, it enables centralized monitoring and control of these devices, integrating serial data into larger automation workflows.

Automated Test Systems

In electronics manufacturing test stations, the PXI-8423 interfaces with DUTs or test fixtures that use RS-232 for configuration or data output. It can send test parameters to a DUT, receive measurement data, and coordinate with other PXI modules (e.g., the PXI-4071 DMM for measurements or the PXI-2510 switch module for signal routing) to execute complete test sequences. The module’s multi-port design allows testing of multiple serial devices in parallel, increasing test throughput.

Legacy Instrument Control

Many laboratory instruments (e.g., oscilloscopes, signal generators, and power supplies) still use RS-232 for remote control. The PXI-8423 enables these legacy instruments to be integrated into modern PXI test systems, allowing them to be controlled and monitored alongside newer PXI modules. For example, in a research lab, it can send commands to a serial-equipped function generator to adjust output signals while the PXI-4462 module measures the response, with the PXI-8186 coordinating the entire process.

NI PXI-8423

Related Model Recommendations

NI PXI-1031: A 5-slot PXI chassis that houses the PXI-8423 and other modules, providing a compact platform for serial communication systems. For larger setups, the PXI-1042 (18-slot) offers additional slots.

NI PXI-8186: A PXI controller that manages the PXI-8423, processing serial data and coordinating communication with other PXI modules. It runs application software to handle data logging, command generation, and system synchronization.

NI PXI-6527: A digital I/O module that can be used alongside the PXI-8423 to provide additional control signals for serial devices that require both serial communication and digital triggers.

NI-VISA: Software that provides a standard interface for communicating with the PXI-8423, simplifying programming across different serial devices and ensuring compatibility with NI development environments like LabVIEW.

NI GPIB-USB-HS: A USB-to-GPIB adapter that, when used with the PXI-8423 and a PXI controller, allows integration of GPIB instruments into systems that also require serial communication, creating a mixed-interface test setup.

Installation, Commissioning, and Maintenance

Installation Steps

Module Insertion: Power off the PXI chassis (e.g., PXI-1031). Insert the PXI-8423 into an available peripheral slot, ensuring it is fully seated in the backplane. Secure the module with front-panel screws to prevent movement during operation.

Device Connection: Connect serial devices to the module’s DB-9 ports using appropriate RS-232 cables. Ensure that the cables are properly shielded to minimize electromagnetic interference (EMI), especially in industrial environments.

Software Installation: Install NI-VISA and the necessary device drivers on the PXI controller (e.g., PXI-8186). Launch NI Measurement & Automation Explorer (MAX) to verify that the PXI-8423 is detected and recognized by the system.

Commissioning

Port Configuration: Use MAX to configure each serial port’s settings, including baud rate, data bits, parity, stop bits, and flow control, to match the requirements of the connected devices. Save configurations for quick recall in different applications.

Communication Test: Perform a loopback test on each port by connecting a DB-9 loopback plug (shorting TXD to RXD) and sending test data. Verify that the data is received correctly, confirming that the port is functioning properly.

System Integration Test: Connect the PXI-8423 to actual serial devices (e.g., a PLC or a serial sensor) and verify that communication is established. Test sending commands and receiving responses to ensure that the module integrates correctly with the rest of the PXI system.

Maintenance Tips

Cable Inspection: Regularly inspect RS-232 cables for damage, such as frayed wires or loose connectors. Replace damaged cables to prevent communication errors or data loss.

Port Cleaning: Periodically check the DB-9 ports for dust, corrosion, or bent pins. Clean ports with compressed air or a soft brush; use a pin straightener (if necessary) to correct bent pins, taking care not to damage the port.

Driver Updates: Keep NI-VISA and device drivers up to date to ensure compatibility with the latest operating systems and to benefit from bug fixes and performance improvements.

Environmental Control: Operate the module within its specified temperature (0 °C to 55 °C) and humidity ranges. Avoid exposure to excessive vibration, dust, or moisture, which can degrade performance over time.

Service and Guarantee Commitment

The NI PXI-8423 is backed by a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ global technical support team provides 24/7 assistance for installation, troubleshooting, and software integration via phone, email, and online resources.

NI offers repair services for the module, ensuring that it meets original performance specifications. Extended warranty plans are available for customers requiring long-term support. With a focus on reliability, the PXI-8423 is engineered to deliver consistent serial communication performance in demanding PXI systems, backed by NI’s commitment to quality and customer success.