Description

Key Technical Specifications

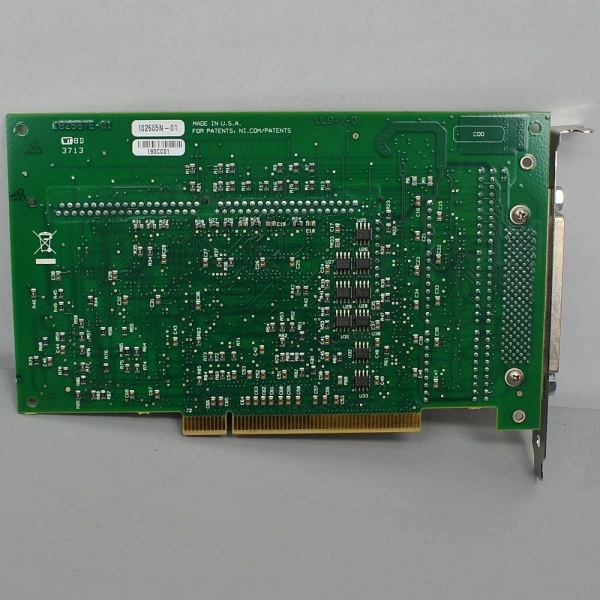

- Model Number: PCI-MXI-2

- Manufacturer: National Instruments (NI)

- Bus Compliance: Complies with PCI Specification 2.0 and MXI Bus Specification 2.0

- Data Path & Memory: 32 – bit data path; minimum 32KB programmable memory space, and can be installed with up to 16MB of DRAM

- Data Transfer Rate: Peak burst throughput of 33MB/s for MXI transmission, 132MB/s maximum PCI master performance (16 double words)

- Core Hardware: Integrates MITE custom ASIC for high-performance DMA transfers; onboard EEPROM with factory and user configuration sections to store default register values

- Physical Dimensions: 6.875 × 4.2 inches, weight 0.4 pounds (without DRAM installed)

- Bus Control Capabilities: Directly controls MXI bus interrupt levels, utility signals, TTL triggers, and CLK10 signals

- Software Compatibility: Works with NI-VXI/NI-VISA software; compatible with LabVIEW, LabWindows/CVI, Measurement Studio; configurable via MAX tool

- Operating Temperature: Typically adapted to industrial and laboratory environments (0°C – 55°C, consistent with common NI PCI card operating standards)

- Special Functions: Supports MXI bus termination, which can terminate MXI bus signals through single in-line package termination resistor networks

NI PCI-MXI-2

Field Application & Problem Solved

In test and industrial control fields, many professional test systems (such as VXI – based modular test platforms) and industrial control equipment use the MXI bus, while most industrial computers and workstations are equipped with PCI expansion slots. There is a serious bus mismatch problem between the two, which leads to obstacles in data interaction between computers and test/control equipment, and even makes it impossible to realize centralized control of the system.

NI PCI-MXI-2 solves this core problem by building a high-speed bridge between the PCI bus and the MXI bus. In the electronic equipment testing workshop, it can connect the PCI industrial computer to the VXI modular test instrument, realizing centralized collection and analysis of multi-channel test data of electronic components. In the aerospace field, it is used to connect the ground PCI control computer with the MXI bus – based sensor array on the aircraft component test bench to ensure the real-time transmission of test data such as pressure and temperature.

In the industrial automation production line, it helps the PCI – based central control computer to communicate with the MXI bus – connected actuators and detectors, solving the problem of scattered control of multiple devices. Its core value lies in breaking the bus barrier between different systems, enabling low – cost upgrading and expansion of existing PCI computers and legacy MXI bus equipment without replacing the entire system.

Installation & Maintenance Pitfalls (Expert Tips)

- Incorrect Bus Termination in Daisy – Chain Connections: When the card is in the MXI bus daisy – chain, only the first and last instruments need to be terminated. Many users mistakenly add termination resistors to all nodes, resulting in signal distortion and reduced transmission rate. It is necessary to confirm the card’s position in the daisy chain first, and only use the single in-line termination resistor network for the end nodes.

- Random Modification of EEPROM Configuration Switches: The EEPROM’s U17 switches 3 and 4 are key configuration bits. Novice maintenance personnel often modify these switches when adjusting parameters, leading to failure to load the default configuration and failure to start the card. It should be clearly marked during maintenance, and non – professional personnel are prohibited from touching these two switches.

- Outdated Driver Leading to Compatibility Issues: If the NI-VXI/NI-VISA driver is not updated in time, the card may not be recognized by LabVIEW and other upper – layer software. For example, an electronics test lab encountered a situation where the card could not communicate with the test program. The root cause was that the driver version did not match the newly upgraded LabVIEW. Updating to the matching NI-VXI/NI-VISA driver solved the problem.

- Ignoring PCI Slot Power Supply Limitations: Although the card has low power consumption, when installed in an old industrial computer with insufficient PCI slot power supply, it will cause intermittent disconnection during high – speed data transmission. It is necessary to test the power supply stability of the PCI slot in advance, and avoid installing it together with other high – power PCI cards in the same chassis.

NI PCI-MXI-2

Technical Deep Dive & Overview

The core advantage of the NI PCI-MXI-2 lies in its efficient bus conversion and stable data transmission mechanism. The integrated MITE custom ASIC is the key to its high performance. This chip realizes high – speed DMA transmission, which avoids the occupation of CPU resources by traditional PIO transmission mode, and ensures that the computer can simultaneously handle other test control tasks while transmitting a large amount of data.

In terms of protocol adaptation, it follows PCI 2.0 and MXI 2.0 dual standards. It is not only compatible with most PCI – based computers, but also can be recognized as a VXI bus device by other MXI bus instruments due to its consistent communication register set with VXI bus devices. This cross – protocol recognition ability makes it very flexible in the integration of mixed bus systems.

The design of the onboard EEPROM also reflects its reliability. The factory configuration section stores the backup of default settings. Even if the user configuration is wrong or modified by mistake, the card can still start normally through the factory configuration, which greatly reduces the maintenance difficulty in industrial and test scenarios.

Although it is an obsolete product of NI, it is still widely used in legacy test and control systems. Compared with the later MXI-Express series, its 33MB/s transmission rate is not outstanding, but for scenarios such as traditional VXI system expansion and low – speed high – stability data transmission, it has the advantages of low cost and strong compatibility. It is still an important supporting component in many industrial sites and laboratories that have not completed the upgrade of new bus systems.