Description

Detailed parameter table

| Parameter name | Parameter value |

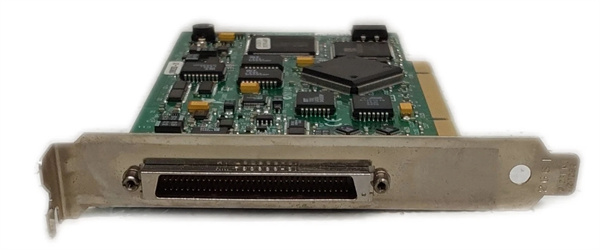

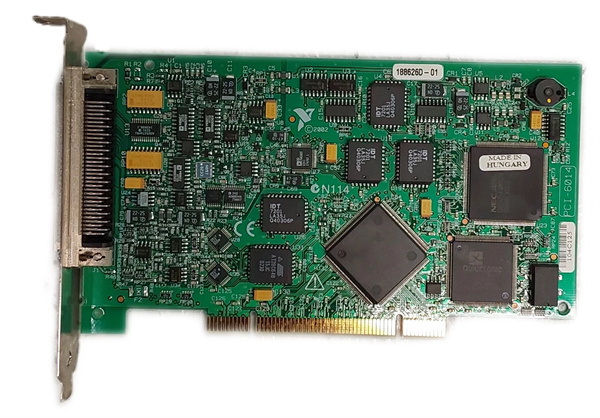

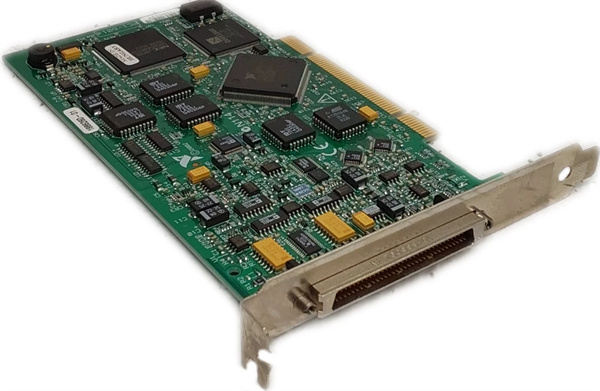

| Product model | NI PCI-6014 |

| Manufacturer | National Instruments (NI) |

| Product category | Multifunction Data Acquisition (DAQ) Card (PCI Interface) |

| Electrical performance | Analog Input: 16 single-ended / 8 differential channels; Resolution: 12-bit; Sampling rate: Up to 200 kS/s (single-channel), 100 kS/s (multichannel); Input range: ±0.5 V, ±1 V, ±2.5 V, ±5 V, ±10 V (software-selectable)Analog Output: 2 channels; Resolution: 12-bit; Output range: 0–5 V, 0–10 V, ±5 V (selectable); Update rate: 100 kS/s per channelDigital I/O: 16 lines (8 input/8 output, configurable); Counter/Timer: 2 × 24-bit up/down counters; PWM output: Supported via counter/timer |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 180 g |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); 68-pin SCSI-II connector for analog/digital signals; 10-pin header for counter/timer signals |

| Communication protocol | PCI bus for data transfer; Compatible with NI-DAQmx driver software; Supports register-level programming and SCPI (Standard Commands for Programmable Instruments) |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Operating altitude: Up to 2000 m; Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); Designed for integration into desktop PCs, industrial control systems, and lab workstations |

| Performance indicators | Analog input accuracy: ±0.01% full scale (FS) at 25 °C; Analog output accuracy: ±0.1% FS; Digital I/O voltage levels: 5 V TTL/CMOS; Counter frequency: Up to 80 MHz; FIFO buffer: 8 kB for analog input, 4 kB for analog output |

| Power requirements | Powered by PCI bus (no external power supply needed); Typical power consumption: 4 W; Peak power consumption: 6 W (during high-speed sampling) |

| Compatibility | Works with Windows 7/10/11 (32-bit/64-bit); Compatible with NI LabVIEW, LabWindows/CVI, C/C++, .NET, Python; Supports legacy NI-DAQ (Traditional DAQ) for backward compatibility; Integrates with NI TestStand for test automation |

| Special features | Software-selectable input gain; Programmable anti-alias filter (for analog input); Digital debouncing (for noisy digital signals); Support for single-point and buffered acquisition; Hot-swappable terminal block compatibility (e.g., NI TB-2707) |

NI PCI-6014

Product introduction

The NI PCI-6014 is a versatile multifunction data acquisition (DAQ) card developed by National Instruments (NI), a global leader in test, measurement, and automation technology. As a flagship product in NI’s mid-range DAQ lineup—trusted for balancing performance and cost—it is engineered to deliver comprehensive analog, digital, and counter/timer capabilities directly from a PC’s PCI slot, making it ideal for a wide range of industrial and laboratory applications.

Designed for test engineers, system integrators, and researchers, the NI PCI-6014 combines 16-channel analog input (200 kS/s sampling), 2-channel analog output, and 16 digital I/O lines in a single card—eliminating the need for multiple specialized modules. Unlike entry-level DAQ cards, its 12-bit resolution and 200 kS/s sampling rate handle both fast transient signals (e.g., motor vibration) and slow-changing parameters (e.g., temperature), while software-selectable input ranges adapt to diverse sensor outputs (from 0.5 V to 10 V).

At its core, the NI PCI-6014 merges flexibility with ease of use. Powered by NI’s NI-DAQmx driver, it integrates seamlessly with NI’s software ecosystem: LabVIEW for visual programming (e.g., building real-time dashboards), TestStand for automated test sequences, and Python for script-based control. Its programmable anti-alias filter and digital debouncing further ensure signal integrity, critical for noisy industrial environments. Whether used to monitor a manufacturing process, control a small robotic system, or log sensor data in a research lab, the NI PCI-6014 delivers reliable, high-quality data acquisition that drives efficient decision-making.

Core advantages and technical highlights

Balanced Speed and Precision for Diverse Tasks

The NI PCI-6014 strikes an ideal balance between sampling speed and measurement accuracy, making it suitable for mixed-signal applications. Its 200 kS/s single-channel sampling rate captures fast signals like motor current spikes (common in industrial control), while 12-bit resolution ensures precise measurements of low-level signals (e.g., 1 mV changes from a strain gauge). For example, in a HVAC system test, the NI PCI-6014 can sample temperature sensor data (slow-changing, 10 kS/s) and fan motor vibration (fast, 100 kS/s) simultaneously—no need to switch between devices. The software-selectable input ranges (±0.5 V to ±10 V) further enhance versatility: use ±0.5 V for high-sensitivity sensors (e.g., load cells) and ±10 V for industrial transducers.

All-in-One Functionality Reduces System Complexity

Unlike single-function DAQ cards, the NI PCI-6014 integrates analog input/output, digital I/O, and counter/timer capabilities—cutting hardware costs by up to 50% and simplifying system design. In a small-scale automation project (e.g., a lab-scale robotic arm), the NI PCI-6014 handles all key tasks: analog input to measure joint position (via potentiometers), analog output to control motor voltage, digital I/O to trigger limit switches, and counters to track encoder pulses. This integration eliminates the need for separate motor control cards or digital I/O modules, reducing wiring complexity and potential points of failure. The 8 kB analog input FIFO buffer also prevents data loss during high-traffic periods, ensuring smooth operation in time-sensitive applications.

Robust Signal Integrity Features

The NI PCI-6014 includes hardware and software features that ensure clean, reliable data—critical for noisy industrial environments. Its programmable anti-alias filter reduces high-frequency noise (e.g., 50 Hz power line interference) from analog input signals, while digital debouncing filters out electrical glitches from switches or sensors. For instance, in a factory setting with heavy machinery, the anti-alias filter ensures temperature measurements (from a thermocouple) remain stable, even when nearby motors generate electromagnetic interference. Additionally, the card’s 5 V TTL-compatible digital I/O lines withstand voltage fluctuations, making them suitable for connecting to industrial sensors or PLCs without additional signal conditioning.

Seamless Software Integration for Fast Deployment

The NI PCI-6014 leverages NI’s industry-leading software tools to accelerate application development. NI-DAQmx driver simplifies low-level configuration: users can set up channels, triggers, and filters via a graphical interface or code, without mastering complex hardware registers. LabVIEW’s pre-built VIs let users build custom data acquisition systems in hours—for example, a dashboard that plots analog input data in real time and sends email alerts if values exceed thresholds. For legacy systems, the NI PCI-6014 supports Traditional DAQ, ensuring compatibility with older LabVIEW projects. This software flexibility lowers the barrier to entry, making the card accessible to both novice users (via LabVIEW’s drag-and-drop interface) and experts (via C/C++ programming).

Typical application scenarios

Industrial Process Monitoring

In manufacturing, the NI PCI-6014 is used to monitor critical process parameters. A plastic injection molding plant, for example, connects the card to temperature sensors (thermocouples) in mold cavities (analog input) and pressure transducers in hydraulic lines. The NI PCI-6014 samples data at 50 kS/s, logging temperature and pressure values to a PC. LabVIEW software analyzes the data to detect anomalies (e.g., a sudden temperature spike) and triggers a digital output to stop the machine if thresholds are exceeded. The analog output also adjusts the hydraulic pressure in real time, ensuring consistent part quality. This system reduces defects by 30% compared to manual monitoring, saving the plant thousands in rework costs.

Laboratory Research and Education

In academic and industrial labs, the NI PCI-6014 supports experiments requiring multi-signal acquisition. A materials science lab might use the card to study the mechanical properties of a new alloy: analog input measures strain (from a strain gauge) and load (from a load cell) during a tensile test, while counters track the test machine’s displacement (via an encoder). The NI PCI-6014’s 200 kS/s sampling rate captures the alloy’s stress-strain curve accurately, even during rapid failure. For education, the card is used in university electronics labs to teach students about DAQ fundamentals—students build projects like a weather station that logs temperature, humidity (analog input), and rain detection (digital input) data, then visualizes it in LabVIEW.

Automated Test Systems (ATE)

In electronics manufacturing, the NI PCI-6014 is a key component of ATE for testing consumer devices (e.g., smartphones, wearables). A test engineer might integrate the NI PCI-6014 into a system that validates a smartphone’s battery charger: analog input measures the charger’s output voltage/current, digital I/O simulates user button presses, and analog output controls the test load. NI TestStand automates the test sequence: the NI PCI-6014 applies different load conditions (0.5 A to 2 A), logs data, and compares results to specifications. This system tests 200+ chargers per hour, ensuring compliance with safety standards (e.g., IEC 61558) and reducing manual testing time by 70%.

NI PCI-6014

Related model recommendations

NI PCI-6221

A high-performance upgrade to the NI PCI-6014, offering 16-bit resolution (vs. 12-bit) and 250 kS/s sampling rate (vs. 200 kS/s). It retains the NI PCI-6014’s multifunction design but adds features like simultaneous sampling and better noise immunity—ideal for users needing higher precision (e.g., aerospace component testing) beyond the NI PCI-6014.

NI USB-6008

A USB-powered DAQ module that complements the NI PCI-6014. Unlike the PCI-based NI PCI-6014, it’s portable and works with laptops—perfect for field service (e.g., troubleshooting industrial equipment) or temporary test setups. It shares similar analog/digital functionality (8 analog inputs, 2 outputs) and NI-DAQmx compatibility.

NI PCI-6013

A sibling model to the NI PCI-6014, with 16 analog inputs (same as NI PCI-6014) but lower sampling rate (100 kS/s single-channel vs. 200 kS/s). It’s a cost-effective choice for applications where speed is not critical (e.g., slow process monitoring) while retaining the NI PCI-6014’s digital I/O and counter features.

NI 9205

A CompactDAQ module that pairs with the NI PCI-6014 for distributed systems. The NI PCI-6014 handles local DAQ in a control room PC, while the 9205 (installed in a CompactDAQ chassis) collects data from remote sensors (e.g., in a factory warehouse). Both use NI-DAQmx, ensuring consistent data formatting across the system.

NI LabVIEW 2024

Essential software for maximizing the NI PCI-6014’s capabilities. It provides pre-built VIs for analog input logging, digital I/O control, and counter/timer operations—letting users build custom systems in minutes. For example, engineers can use LabVIEW to create a real-time dashboard that plots NI PCI-6014 sensor data and sends alerts if values exceed thresholds.

NI PCI-485I2

An industrial serial communication card that works alongside the NI PCI-6014 in hybrid systems. The NI PCI-6014 collects analog/digital data, while the PCI-485I2 sends that data to remote PLCs via RS-485—ideal for small factories that need to integrate local DAQ with industrial control networks.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PCI-6014, power off the PC and confirm it has an empty PCI slot (PCI 2.1/2.2/2.3 compliant). Wear an ESD wristband to prevent electrostatic damage. Insert the card firmly into the slot and secure it with the chassis screw. Connect sensors/devices to the 68-pin SCSI-II terminal block: use shielded cables for analog signals (to reduce noise) and ensure proper polarity (positive/negative) for voltage inputs. For counter/timer applications, connect encoders or pulse generators to the 10-pin header. Download and install the latest NI-DAQmx driver from NI’s website. Use NI’s Measurement & Automation Explorer (MAX) to verify the card is detected, run a self-test, and calibrate analog channels (follow NI’s calibration wizard for accuracy). For automated test setups, configure triggers via MAX to synchronize data acquisition with external events (e.g., a sensor signal).

Maintenance suggestions

To maintain the NI PCI-6014’s performance, inspect the 68-pin connector quarterly for loose pins or corrosion—clean contacts with isopropyl alcohol and a lint-free cloth, and tighten terminal block screws if needed. Avoid exposing the PC (and card) to extreme temperatures (0 °C–55 °C) or moisture, as this can degrade component performance. If analog measurements drift, recalibrate the card using MAX’s calibration tool (recommended annually for precision applications). For digital I/O issues, check for damaged cables (replace if frayed) and verify TTL voltage levels (5 V) with a multimeter. Update NI-DAQmx periodically to access bug fixes for new operating systems. Use only NI-compatible terminal blocks (e.g., NI TB-2707) for repairs—third-party blocks may cause signal interference or damage the card’s input circuits.

Service and guarantee commitment

National Instruments (NI) backs the NI PCI-6014 with a 2-year standard warranty, covering defects in materials and workmanship. For extended protection, customers can purchase NI’s ServicePlus Premium plan, which extends coverage up to 5 years and includes priority technical support, annual calibration, and expedited repairs. NI’s global technical team—specialized in multifunction DAQ—is available 24/7 via phone, email, and chat to assist with calibration, software integration, or troubleshooting (e.g., resolving trigger synchronization issues or data loss problems).

NI also provides free access to a wealth of resources for the NI PCI-6014: application notes on mixed-signal DAQ, LabVIEW example code for automated testing, and a user community where engineers share best practices. For out-of-warranty repairs, NI offers a flat-rate service that restores the card to factory specifications—including recalibration of its analog circuits to meet original accuracy standards. This commitment reflects NI’s confidence in the NI PCI-6014’s durability and its dedication to supporting customers in their most critical data acquisition tasks.