Description

Detailed parameter table

| Parameter name | Parameter value |

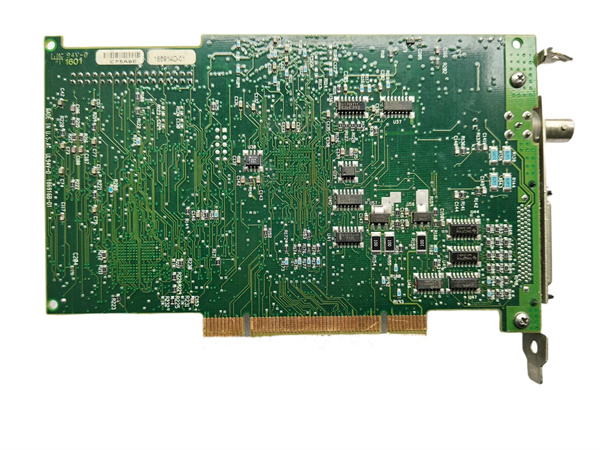

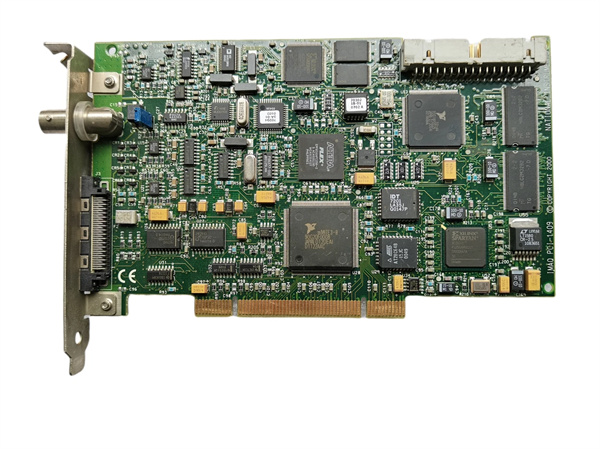

| Product model | NI PCI-1409 |

| Manufacturer | National Instruments (NI) |

| Product category | Ultra-High-Channel Analog Machine Vision Frame Grabber (PCI Interface) |

| Electrical performance | Image sensor support: Monochrome/color analog cameras (progressive-scan/interlaced); Input type: 8× composite video (NTSC/PAL/SECAM), 4× S-Video (Y/C); Resolution: Up to 1600 × 1200 (progressive-scan), 768 × 576 (PAL interlaced), 768 × 480 (NTSC interlaced); Frame rate: 75 fps (NTSC progressive), 60 fps (PAL progressive), 30 fps (NTSC interlaced), 25 fps (PAL interlaced); Analog input range: 0.5–2.0 Vpp (composite), 0.7 Vpp (Y/C luma), 0.3 Vpp (Y/C chroma) |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 210 g |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); BNC connectors (8× composite video, 4× S-Video); 4× DB-9 connectors for trigger/control signals; 4× 15-pin D-subs for camera power (12 VDC, 1.5 A max per port) |

| Communication protocol | PCI bus for high-speed data transfer; Compatible with NI-IMAQ 4.0+ driver software; Supports direct memory access (DMA), scatter-gather DMA, and burst-mode transfer for low-latency imaging |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Operating altitude: Up to 3000 m; Vibration resistance: 3 g (10 Hz to 500 Hz); Shock resistance: 60 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); Designed for high-channel industrial vision systems, lab automation setups, and multi-camera inspection lines |

| Performance indicators | Image processing: 12-bit A/D conversion (vs. 10-bit in NI PCI-1408), real-time 3D noise reduction, dynamic white balance, adaptive gamma correction; Trigger modes: Software, external hardware (edge/pulse/pattern), multi-camera synchronous/asynchronous trigger; Buffer size: 64 MB on-board frame buffer; Data transfer rate: Up to 132 MB/s via PCI bus (optimized for multi-channel concurrent transfer) |

| Power requirements | Powered by PCI bus + optional 12 VDC external power (for high-power cameras); Camera power output: 12 VDC (1.5 A max per port, 6 A total); Typical power consumption: 7 W (bus-powered), 12 W (with external power) |

| Compatibility | Works with Windows 7/10/11 (32-bit/64-bit); Compatible with NI LabVIEW, LabWindows/CVI, C/C++, .NET, Python; Supports NI Vision Development Module (v2012–2024); Compatible with all analog industrial cameras (NTSC/PAL/SECAM, progressive/interlaced) |

| Special features | 12-camera concurrent support (8 composite + 4 S-Video); Advanced trigger cascading (up to 32 cameras via daisy-chain); On-board FPGA for real-time image preprocessing; Overvoltage/overcurrent/short-circuit protection for camera ports; Support for analog-to-digital workflow migration (backward compatibility with NI PCI-1408 projects) |

NI PCI-1409

Product introduction

The NI PCI-1409 is an ultra-high-channel analog machine vision frame grabber developed by National Instruments (NI), a pioneer in test, measurement, and automation technology. As the flagship model in NI’s legacy analog frame grabber lineup—engineered for high-throughput, multi-camera industrial inspection and advanced scientific imaging—the NI PCI-1409 redefines analog imaging capabilities by converting high-fidelity analog signals into detailed digital images, even in complex, multi-device setups.

Designed for system integrators, quality control directors, and research engineers, the NI PCI-1409 addresses the limitations of mid-tier models like the NI PCI-1408: it supports up to 12 concurrent analog cameras (8 composite + 4 S-Video), 1600×1200 progressive-scan resolution, and 75 fps frame rates—making it ideal for large-scale inspection lines (e.g., automotive component testing) or multi-angle scientific imaging (e.g., 3D object scanning). Unlike the NI PCI-1408, its 12-bit A/D conversion and 64 MB on-board buffer capture finer grayscale gradients and prevent data loss when all 12 cameras are active.

At its core, the NI PCI-1409 merges industrial scalability with software flexibility. Powered by NI’s NI-IMAQ driver, it integrates seamlessly with the NI Vision Development Module, letting users build custom systems for 360° product inspection, multi-sensor data correlation, or high-speed defect detection in LabVIEW. Its advanced trigger cascading and FPGA-based preprocessing also enable real-time decision-making—critical for lines where every millisecond of inspection time impacts productivity. Whether used to inspect 12 sides of an automotive gear simultaneously, analyze multi-angle cell imaging in biology labs, or verify pharmaceutical blister packs at scale, the NI PCI-1409 delivers consistent, high-resolution imaging that drives operational efficiency.

Core advantages and technical highlights

12-Camera Concurrent Acquisition & Scalability

The NI PCI-1409 sets a benchmark for analog frame grabbers with support for 12 concurrent cameras (8 composite + 4 S-Video)—double the capacity of the NI PCI-1408. This scalability is transformative for large-scale inspection: in an automotive transmission factory, for example, the NI PCI-1409 can connect 12 cameras to inspect every gear tooth, bearing seat, and seal surface of a transmission housing simultaneously. Its optimized PCI bus transfer (132 MB/s) ensures no dropped frames, even when all 12 cameras stream 1600×1200 images at 60 fps. For even larger setups, trigger cascading lets users daisy-chain up to 32 cameras across multiple NI PCI-1409 cards—eliminating the need for expensive digital camera upgrades.

12-Bit A/D Conversion for Ultra-Precise Imaging

With 12-bit A/D conversion (vs. 10-bit in the NI PCI-1408), the NI PCI-1409 captures 4096 grayscale levels—four times more detail than 10-bit grabbers. This precision is critical for applications where subtle variations matter: in semiconductor wafer inspection, for instance, the NI PCI-1409 can distinguish between 0.02 mm differences in solder paste height, a detail invisible to lower-bit models. The 1600×1200 resolution further enhances this precision, enabling measurements of micro-scale defects (e.g., 0.01 mm scratches on optical components) that would be blurred in lower-resolution imaging. For scientific research, this level of detail makes the NI PCI-1409 ideal for fluorescence microscopy, where it can capture faint signal variations from labeled cells.

FPGA-Powered Real-Time Preprocessing

The NI PCI-1409 includes an on-board FPGA (field-programmable gate array) that accelerates image preprocessing—reducing host PC workload by up to 70% compared to the NI PCI-1408. Features like 3D noise reduction (which filters out environmental noise without blurring edges) and dynamic white balance (which adjusts for lighting shifts in real time) are processed directly on the card, ensuring only clean, analysis-ready images are sent to the PC. In a food packaging plant, for example, the FPGA can instantly correct for uneven LED lighting on a conveyor line, ensuring consistent color analysis of labels—even as lighting conditions change. This real-time processing also enables faster decision-making: the NI PCI-1409 can trigger a reject mechanism in under 10 ms when a defect is detected, critical for high-speed lines.

Rugged Power & Protection for Industrial Reliability

Built for harsh industrial environments, the NI PCI-1409 includes robust protection features absent in mid-tier models. Its camera power ports (12 VDC, 1.5 A per port) have overvoltage, overcurrent, and short-circuit protection—preventing damage from faulty cameras or wiring errors. Unlike the NI PCI-1408 (2 A total camera power), the NI PCI-1409’s 6 A total output supports power-hungry devices like high-resolution analog microscopes or IR cameras, eliminating the need for external power supplies. The card also withstands higher vibration (3 g vs. 2 g) and shock (60 g vs. 50 g) than the NI PCI-1408, making it suitable for heavy-industry applications like metal stamping or automotive assembly—where equipment is exposed to constant movement.

Typical application scenarios

Automotive Component 360° Inspection

In automotive manufacturing, the NI PCI-1409 is used for comprehensive 360° inspection of complex components like engine blocks or transmission gears. A manufacturer might connect 12 cameras (8 composite + 4 S-Video) around a conveyor line, each capturing a unique angle of the component. The NI PCI-1409’s trigger cascading ensures all cameras capture images simultaneously when the component is in position, while its 12-bit resolution detects micro-defects like hairline cracks or incomplete machining. NI Vision software then stitches the images into a 3D model, verifying dimensions against CAD data. This system reduces inspection time by 80% compared to sequential single-camera setups and eliminates human error, ensuring only defect-free components reach assembly lines.

Multi-Modal Scientific Imaging

In academic research, the NI PCI-1409 supports multi-modal imaging—combining data from different camera types to study complex phenomena. A materials science lab, for example, uses 4 S-Video cameras (for high-quality visible light imaging) and 8 composite cameras (for IR imaging) connected to the NI PCI-1409 to study heat distribution in a battery during charging. The card’s synchronized acquisition aligns visible and IR images, while its 12-bit resolution captures subtle temperature variations (as low as 0.1 °C) in the IR stream. LabVIEW integration lets researchers automate time-lapse imaging (capturing data every 2 seconds) and correlate heat patterns with battery performance—accelerating the development of safer, more efficient batteries.

High-Volume Pharmaceutical Blister Pack Inspection

In pharmaceutical manufacturing, the NI PCI-1409 ensures compliance with strict quality standards for blister packs. A drug manufacturer might use 12 cameras connected to the NI PCI-1409 to inspect 1,800 packs per minute: 4 cameras check for missing pills, 4 verify label text and barcodes, and 4 inspect seal integrity. The NI PCI-1409’s FPGA preprocessing corrects for lighting variations on the line, while its 75 fps frame rate keeps up with high throughput. If a defect is detected (e.g., a missing pill or misprinted label), the card triggers a reject mechanism in real time—preventing non-compliant products from reaching consumers. The NI PCI-1409’s compatibility with legacy analog cameras also lets the manufacturer reuse existing hardware, reducing upgrade costs by 50%.

NI PCI-1409

Related model recommendations

NI PCI-1408

A mid-tier analog frame grabber and predecessor to the NI PCI-1409. It supports 6 cameras (4 composite + 2 S-Video), 10-bit A/D conversion, and 60 fps frame rates—ideal for medium-scale applications (e.g., small electronics inspection) where 12 cameras aren’t needed. The NI PCI-1409 is a direct upgrade for users scaling to larger multi-camera setups.

NI PCIe-1433

A PCI Express frame grabber that replaces the NI PCI-1409 for modern PCs. It retains the NI PCI-1409’s 12-camera support and 12-bit resolution but adds digital camera compatibility (GigE Vision, USB3 Vision) and faster PCIe x4 data transfer (up to 1 GB/s). It’s a future-proof choice for users upgrading from PCI to PCIe chassis while preserving analog camera investments.

NI 1792

A standalone smart camera that pairs with the NI PCI-1409 in distributed systems. The NI PCI-1409 handles centralized processing in a control room PC, while the 1792 (with on-board FPGA) captures and analyzes images in remote factory zones (e.g., warehouse packaging lines). Both use NI Vision software, ensuring consistent defect detection across the entire facility.

NI Vision Development Module 2024

Essential software for maximizing the NI PCI-1409’s capabilities. It adds advanced tools like 3D point cloud generation (for multi-camera stitching), OCR with font training (for pharmaceutical labels), and defect classification (for automotive components). For example, it lets users program the NI PCI-1409 to classify a scratch as “minor” or “critical” based on size and depth.

NI PCI-6363

A high-speed multifunction DAQ card that works with the NI PCI-1409 in hybrid test systems. The NI PCI-1409 captures images of a product, while the PCI-6363 collects analog data (e.g., pressure, vibration) from the same line—enabling correlated analysis (e.g., linking blister pack seal defects to sealing machine pressure).

NI PXIe-1085

A PXI Express chassis that can host the NI PCI-1409 (via PCI-to-PXI adapter) for modular test systems. It provides stable power and high-speed synchronization for multi-card setups—ideal for users combining the NI PCI-1409 with other PXIe modules (e.g., signal generators, switches) to build comprehensive inspection solutions.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PCI-1409, power off the PC and confirm it has an empty PCI slot (PCI 2.1/2.2/2.3 compliant). For high-power camera setups (total current >7 W), connect the optional 12 VDC external power supply to the card’s power port. Wear an ESD wristband to prevent electrostatic damage. Insert the card firmly into the slot and secure it with the chassis screw. Connect cameras to BNC/S-Video ports: use 75 Ω coaxial cables for composite signals (to avoid loss) and shielded S-Video cables for color accuracy. For 12-camera setups, connect a master trigger (e.g., conveyor encoder) to one DB-9 port and cascade triggers to other cameras via the remaining DB-9s. Use 15-pin D-subs to power cameras—ensure total current does not exceed 6 A. Download and install NI-IMAQ 4.0+ and NI Vision software. Use NI MAX to verify camera detection, run a self-test, and calibrate white balance/gamma settings to match your lighting.

Maintenance suggestions

To maintain the NI PCI-1409’s performance, inspect BNC/S-Video/DB-9 connectors quarterly: clean contacts with isopropyl alcohol and a lint-free cloth, and tighten loose cables to prevent signal interference. For external power setups, check the 12 VDC supply regularly to ensure it delivers stable voltage. Avoid exposing the PC to extreme temperatures (0 °C–55 °C) or moisture—use a fan-cooled control cabinet for factory installations. If images are noisy, use MAX to adjust the card’s 3D noise reduction settings; if synchronization fails, verify trigger wiring and update NI-IMAQ to the latest version. For hardware issues, use MAX’s self-test tool—if it fails, contact NI support. Use only NI-certified cables and power supplies: third-party accessories may overload the camera power circuit, damaging the card.

Service and guarantee commitment

National Instruments (NI) backs the NI PCI-1409 with a 3-year standard warranty—longer than the NI PCI-1408’s 2-year coverage—covering defects in materials and workmanship. For enterprise customers, NI’s ServicePlus Enterprise plan extends coverage up to 7 years and includes 24/7 priority technical support, on-site calibration, and expedited repairs. NI’s global machine vision experts are available via phone, email, and chat to assist with complex tasks like 32-camera cascading, FPGA preprocessing configuration, or multi-modal image alignment.

NI also provides exclusive resources for the NI PCI-1409: application notes on high-channel analog imaging, LabVIEW example code for 12-camera synchronization, and a dedicated user forum for sharing multi-camera inspection workflows. For out-of-warranty repairs, NI offers a premium service that restores the card to factory specifications—including recalibration of its 12-bit A/D converter and FPGA firmware updates. This commitment reflects NI’s confidence in the NI PCI-1409’s durability and its dedication to supporting customers in their most demanding, large-scale imaging projects.