Description

Detailed Parameter Table

| Parameter name | Parameter value |

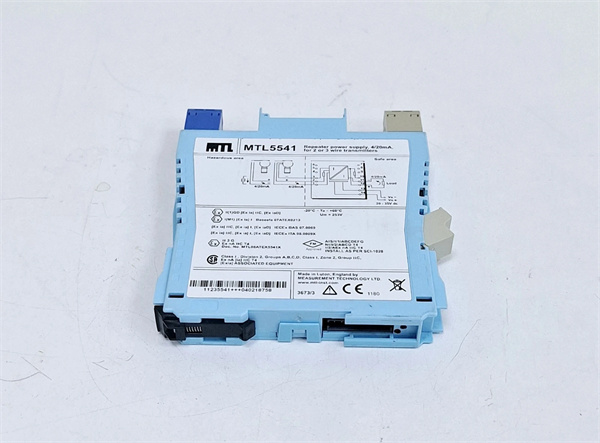

| Product model | MTL-5541 |

| Manufacturer | MTL (a leading name in industrial safety and automation components) |

| Product category | Intrinsic safety barrier |

| Input voltage range | DC 9 – 32 V |

| Output voltage range | DC 0 – 24 V |

| Rated input current | Up to 200 mA |

| Signal type supported | Can handle analog signals (such as 4 – 20 mA current loops for process control variables) and digital signals (e.g., on/off signals for discrete control elements) |

| Isolation features | Galvanic isolation between input and output circuits, providing electrical separation to prevent electrical interference and ensure safety in hazardous areas. The isolation voltage is typically rated at a high value, for example, 2500 Vrms for enhanced protection. |

| Response time | For analog signal processing, the response time is extremely fast, usually in the range of microseconds, ensuring real – time monitoring and control. For digital signals, the switching time is also very short, enabling quick response to changes in the control system. |

| Physical dimensions (approx.) | – Length: Around 100 mm, which is compact enough to fit into standard industrial control panels without taking up excessive space. – Width: Approximately 25 mm, allowing for easy installation in modular control systems. – Height: About 120 mm, designed to be a slim profile for efficient space utilization. |

| Weight (approx.) | Weighing approximately 0.2 kg, it is lightweight, making it convenient for handling during installation, maintenance, and replacement procedures. |

| Protection class | Designed to meet high – level protection standards. For example, it may have an ingress protection rating of IP20, protecting against solid objects larger than 12 mm and preventing accidental contact with live parts. In addition, it is built to withstand harsh industrial environments, with resistance to vibrations, shocks, and temperature variations. |

MTL MTL-5541

Product Introduction

The MTL MTL – 5541 is a high – performance intrinsic safety barrier engineered by MTL, a renowned company in the field of industrial safety and automation. This device plays a crucial role in ensuring the safe operation of electrical equipment in hazardous areas, such as those with the presence of flammable gases, vapors, or dust.

The MTL – 5541 acts as a protective interface between non – hazardous area electrical systems and equipment located in hazardous zones. It limits the energy that can be transferred to the hazardous area, preventing the ignition of flammable substances. By doing so, it enables the use of standard industrial control and monitoring equipment in environments where safety is of utmost importance, such as oil and gas refineries, chemical plants, and mining operations.

Core Advantages and Technical Highlights

Superior Intrinsic Safety Performance

The MTL – 5541 is designed in strict accordance with international intrinsic safety standards, such as IECEx and ATEX. Its advanced circuit design incorporates multiple layers of protection to limit both voltage and current in the event of a fault. For example, in a 4 – 20 mA current loop used for transmitting process variable data in a chemical plant, the MTL – 5541 ensures that any over – voltage or over – current conditions in the non – hazardous area do not cause an ignition source in the hazardous area where the field device is located. This high – level safety performance provides peace of mind for plant operators and helps them comply with strict safety regulations.

High – Speed Signal Processing

Despite its safety – critical functions, the MTL – 5541 does not compromise on signal processing speed. It can rapidly process both analog and digital signals, making it suitable for applications where real – time data transfer is essential. In a fast – paced manufacturing process in a petrochemical plant, where sensors in a hazardous area need to send continuous data on temperature, pressure, or flow rate to a control system in a non – hazardous area, the MTL – 5541 can accurately transmit these signals without significant latency. Its high – speed processing capabilities ensure that the control system can make timely decisions based on the most up – to – date information.

Compact and Modular Design

The compact physical dimensions of the MTL – 5541 make it highly adaptable to various installation scenarios. Its modular design allows for easy integration with other components in a control system. In a crowded industrial control panel, multiple MTL – 5541 units can be installed side – by – side, along with other modules such as power supplies, signal conditioners, and PLCs. This modular approach simplifies system design, installation, and maintenance, as individual modules can be easily replaced or upgraded without affecting the entire system. Additionally, the lightweight nature of the device further facilitates its installation and handling.

Wide Compatibility

The MTL – 5541 is designed to be compatible with a diverse range of field devices and control systems. It can interface with different types of sensors (such as pressure sensors, temperature sensors, and level sensors) and actuators (such as valves and motors) commonly used in industrial applications. Whether it’s a simple on/off sensor in a mining operation or a complex multi – variable transmitter in an oil refinery, the MTL – 5541 can provide the necessary intrinsic safety protection while maintaining seamless communication with the control system. This wide compatibility makes it a versatile solution for different industrial sectors.

Typical Application Scenarios

Oil and Gas Industry

In oil and gas refineries, there are numerous areas classified as hazardous due to the presence of flammable hydrocarbons. The MTL – 5541 is extensively used to interface between control systems in non – hazardous control rooms and field devices in hazardous process areas. For instance, it can protect the signals transmitted from pressure sensors installed on pipelines carrying crude oil or natural gas. By ensuring the safe transfer of these signals, it enables operators to monitor and control the pressure within the pipelines, preventing potential leaks or over – pressure situations that could lead to dangerous explosions.

Chemical Plants

Chemical plants often deal with a variety of flammable and explosive chemicals. The MTL – 5541 plays a vital role in these environments by safeguarding the electrical connections between sensors, actuators, and control systems. In a chemical reactor area, where temperature sensors are used to monitor the reaction process, the MTL – 5541 ensures that the signals from these sensors can be safely transmitted to the control room. If there is a need to adjust the reaction conditions by controlling valves or pumps, the MTL – 5541 also enables the safe transfer of control signals to the actuators in the hazardous area.

Mining Operations

Mining sites, especially those dealing with coal or certain minerals, can have hazardous atmospheres due to the presence of flammable gases or dust. The MTL – 5541 is used to protect the electrical equipment used for monitoring and controlling mining operations. For example, in a coal mine, it can be used to interface between the control system in the surface control room and sensors installed in the underground mine shafts to monitor methane gas levels. By providing intrinsic safety protection, it helps prevent gas explosions and ensures the safety of miners.

Related Model Recommendations

MTL MTL – 5521: This is another intrinsic safety barrier from MTL, which may be suitable for applications with lower current requirements or simpler signal processing needs. It shares similar safety features with the MTL – 5541 but has different electrical specifications. In a small – scale chemical laboratory where the signals are less complex and the power requirements are lower, the MTL – 5521 could be a more cost – effective option.

MTL Power Supply Modules: A reliable power supply is essential for the proper operation of the MTL – 5541. MTL offers a range of power supply modules that are specifically designed to work in harmony with their intrinsic safety barriers. These power supplies can provide a stable DC voltage within the input voltage range required by the MTL – 5541, ensuring its continuous and safe operation. For example, an MTL power supply module with a rated output of 24 V DC and sufficient current capacity can be used to power multiple MTL – 5541 units in a large – scale industrial installation.

Signal Conditioning Modules: In some cases, the signals received or transmitted by the MTL – 5541 may need to be conditioned for better compatibility with other components in the control system. MTL offers signal conditioning modules that can be used in conjunction with the MTL – 5541. These modules can perform functions such as filtering, amplification, or conversion of analog signals. For instance, if the signal from a sensor has a lot of noise, a signal conditioning module can be used to filter out the noise before it reaches the MTL – 5541, ensuring more accurate signal transmission.

MTL MTL-5541

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the MTL MTL – 5541, ensure that the installation area is clean, dry, and free from excessive dust and moisture. Tools required for installation include a screwdriver for securing the module in place and a multimeter to check the electrical integrity of the power supply and signal connections. Disconnect all power sources from the system to avoid electrical shocks during installation. When connecting the input and output wires to the MTL – 5541, make sure to follow the wiring diagram provided in the product manual carefully. The wires should be of appropriate gauge and quality to handle the current and voltage requirements. Also, ensure that the grounding connections are properly made to enhance safety.

Maintenance Suggestions

For routine maintenance of the MTL – 5541, perform visual inspections regularly. Check for any signs of physical damage to the module, such as cracks on the housing or loose connectors. Use a clean, dry cloth to wipe off any dust that may have accumulated on the device. Periodically test the functionality of the MTL – 5541 using a signal generator and a multimeter. Send a known input signal to the module and check if the output signal is as expected. If any issues are detected, refer to the user manual for troubleshooting guidance. Replace any worn – out or damaged components with genuine MTL parts to maintain the integrity of the intrinsic safety protection. It is also advisable to keep a record of the maintenance activities and any issues encountered for future reference.

Service and Guarantee Commitment

MTL provides a comprehensive service and guarantee commitment for the MTL – 5541. The warranty period for this product is typically [Specify the approximate warranty period, e.g., 1 – 2 years]. During this time, if the MTL – 5541 is found to be defective due to manufacturing issues, MTL will, at its discretion, repair or replace the component free of charge. However, the warranty may be subject to certain terms and conditions, such as proper installation and use as per the product manual. MTL also offers technical support services to assist customers with installation, commissioning, and troubleshooting. Customers can access detailed user manuals, installation guides, and other technical resources through MTL’s official channels, which may include their website, customer support hotlines, or dedicated service centers. This commitment to product quality and customer support reflects MTL’s reputation as a leading provider of industrial safety components.