Description

Detailed Parameter Table

**

| Parameter name | Parameter value |

| Product model | Motorola MVME712-12/13 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | I/O Transition Module |

| Serial Ports | Four 25-pin multi-protocol EIA-232-D serial ports (accessible through P2 adapter or LCP2 adapter depending on variant); Configurable as DTE or DCE via jumper settings |

| Printer Port | One independent parallel printer port (connected through P2 or LCP2 adapter) |

| SCSI Interface | SCSI shielded connector bus interface (through P2/LCP2 adapter) for both internal and external device connection; Transfer rate up to 5 MB/s (SCSI-1 standard) |

| Ethernet Interface | External Ethernet interface (for MVME712B, through LCP2 adapter); Supports 10Base-T Ethernet (CSMA/CD, RJ-45); Some variants may support faster speeds with additional modules |

| Built-in Modem | Present in MVME712 – 13 and MVME712AM models; Features front panel Telco modular jack |

| Power Requirements | +5 VDC, maximum 281 mA (255 mA typical); +12 VDC and – 12 VDC also required for operation |

| Environmental Requirements | Operating Temp: 0°C – 55°C (at the point of entry of forced air, approximately 5 cfm); Storage Temp: – 40°C – 85°C; Humidity: 5% – 90% (non-condensing) |

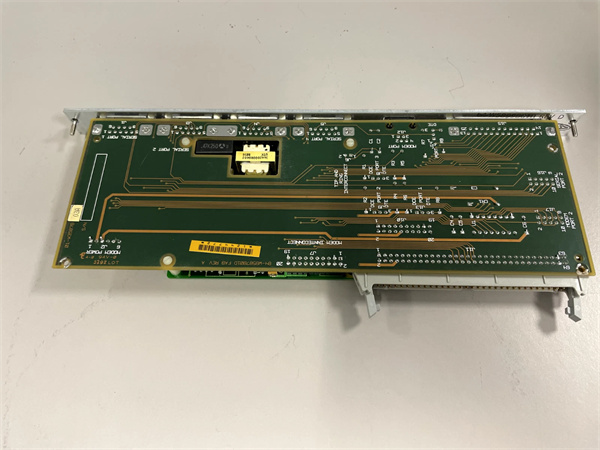

| Physical Size | Length: 9.187 inches (233.35 mm); Width: 3.200 inches (80.00 mm); Thickness: 0.063 inches (1.60 mm) |

| Protective Features | Electrostatic Discharge (ESD) protection on the front panel; Radio Frequency Interference (RFI) protection on the front panel |

| Compatibility | Compatible with Motorola’s MPU VME module families such as MVME147, MVME1600, MVME162, MVME2600, MVME167, MVME2700, MVME177, MVME3600, MVME4600 |

| Product Life Cycle | Likely in a legacy or mature stage, with limited new production but still in use in existing industrial systems |

Motorola MVME712-12/13

Product Introduction

The Motorola MVME712-12/13 is an I/O transition module designed to bridge the gap between Motorola’s processor modules (like those in the MVME147 series and others) and their peripheral devices. It serves as a crucial interface that simplifies external cabling requirements by providing industry-standard connectors on its front panel.

In industrial control and data acquisition systems, the MVME712-12/13 plays a pivotal role. For example, in a factory’s production line control system where an MVME147 processor module is used as the core controller, the MVME712-12/13 can be attached. It enables the connection of multiple serial devices such as barcode scanners, temperature sensors with serial outputs, and other industrial instruments via its four EIA-232-D serial ports. The SCSI interface allows for the connection of storage devices like hard drives for data logging, while the printer port can be used to output reports or labels. The inclusion of an Ethernet interface (in certain variants) and a built-in modem (in the MVME712 – 13) further expands its connectivity options, facilitating communication with other networked devices or remote monitoring systems.

Core Advantages and Technical Highlights

Rich I/O Connectivity Options: The MVME712-12/13 offers a comprehensive set of I/O interfaces. In a logistics warehouse, the four multi-protocol EIA-232-D serial ports can be used to connect two barcode scanners, a label printer with a serial interface, and a temperature/humidity sensor module. The SCSI interface can be linked to a SCSI hard drive, which stores daily inventory data. This eliminates the need for multiple individual interface cards, reducing the complexity and cost of the system setup. Compared to some generic I/O expansion boards, the MVME712-12/13’s interfaces are optimized for industrial use, ensuring reliable communication in noisy factory environments.

Enhanced Protection Features: With ESD and RFI protection on the front panel, the MVME712-12/13 can withstand the harsh electrical and electromagnetic conditions often found in industrial settings. In a power generation plant, where there are high levels of electromagnetic interference from generators and transformers, the MVME712-12/13 can maintain stable operation. The ESD protection safeguards the module from sudden electrostatic discharges that could potentially damage sensitive components, ensuring long-term reliability.

Compatibility with Existing Systems: Given its compatibility with a wide range of Motorola processor modules, the MVME712-12/13 is an ideal choice for upgrading or expanding legacy industrial systems. A manufacturing facility that has been using Motorola MVME167 processor modules for years can easily add an MVME712-12/13 to enhance its I/O capabilities. This allows for the integration of new peripheral devices without having to replace the entire control system, saving both time and money.

Typical Application Scenarios

In a food and beverage production line, the MVME712-12/13 can be used to manage various sensors and actuators. The serial ports can connect to flow sensors, pressure sensors, and level sensors, while the SCSI interface can be used to connect to a data storage device that logs production data. The printer port can be used to print batch labels or production reports. In case of remote monitoring requirements, the Ethernet interface (if available) or the built-in modem (in MVME712 – 13) can be used to send production data to a central control room or a remote server for analysis.

For a water treatment plant, the MVME712-12/13 can interface with multiple water quality sensors, pumps, and valves. The serial ports can communicate with pH sensors, dissolved oxygen sensors, and turbidity sensors. The SCSI interface can be used to store historical water quality data on a hard drive. The Ethernet interface can be used to connect to a local network, allowing operators in the plant to access real-time data from different workstations.

Motorola MVME712-12/13

Related Model Recommendations

MVME712M: Similar I/O transition module but may have different connector configurations or feature sets. It can be considered as an alternative if the MVME712-12/13 does not fully meet specific requirements. For example, if a user needs a slightly different layout of serial ports or additional shielding for a particularly noisy environment.

MVME712B: This variant may offer enhanced Ethernet capabilities compared to the MVME712-12/13. If a project requires a more robust or faster Ethernet connection for high – speed data transfer between the processor module and networked devices, the MVME712B could be a better choice.

P2 Adapter Board (for MVME712 series): Essential for connecting the MVME712-12/13 to the chassis backplane. It routes the I/O signals and grounds from the P2 connector on the backplane to the MVME712-12/13. A high – quality P2 adapter board, such as the one specifically designed for the MVME712 series, ensures stable signal transmission.

LCP2 Adapter Board (for relevant MVME712 variants): In models like the MVME712B where the LCP2 adapter is used, it provides specific functions such as enabling the external Ethernet interface. If a user is considering upgrading the Ethernet capabilities of their MVME712-12/13 – based system, they may need to explore the compatibility and functionality of the LCP2 adapter board.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the MVME712-12/13, ensure that the VMEbus chassis has an available slot compatible with the module’s form factor. Verify that the power supply in the chassis can provide the required +5 VDC, +12 VDC, and – 12 VDC within the specified tolerances. Use a multimeter to check the voltage levels. Gather the necessary tools, including an anti – static wristband to protect the sensitive components during installation, a screwdriver for mounting the module in the chassis, and if required, the appropriate adapter board (P2 or LCP2) along with the associated ribbon cables.

Commissioning process: After physically installing the MVME712-12/13 and the adapter board (if applicable), power on the system. Check the front panel LEDs (if available) for any error indications. Use a terminal emulator software on a laptop connected to one of the serial ports (configured as DTE) to access the module’s configuration settings. Configure the serial ports, SCSI interface, and other interfaces according to the requirements of the connected peripheral devices. For example, set the baud rate, data bits, parity, and stop bits for the serial ports. If using the Ethernet interface, configure the IP address and other network settings.

Maintenance suggestions: For regular maintenance, periodically check the front panel for any signs of physical damage. Clean the module’s surface gently with a dry, lint – free cloth to remove dust, which can cause overheating. Check the connections of the ribbon cables and external cables to ensure they are secure. If there are issues with the serial ports, check the jumper settings to ensure they are correctly configured. If the SCSI interface is not working properly, check the terminator settings on the SCSI bus. Run diagnostic tests (if available) on a monthly basis to detect any potential hardware issues early.

Service and Guarantee Commitment

For refurbished Motorola MVME712-12/13 units, Emerson typically provides a 12 – month warranty. This warranty covers defects in the module’s hardware components such as the serial port controllers, SCSI interface chips, and any other integrated circuits. In case of a failure, such as a non – functioning serial port or a damaged SCSI connector, Emerson will provide a replacement unit within a specified time frame, usually 10 – 15 business days. This is crucial for industrial users where downtime can lead to significant production losses.

For extended support, customers can opt for a 24 – month service contract. This contract includes technical support via phone or email on weekdays, access to archived driver files and configuration guides, and remote troubleshooting assistance. Emerson also maintains a stock of spare parts for the MVME712-12/13 for a certain period, ensuring that customers can continue to use and maintain their legacy systems without major disruptions. This long – term support commitment helps users avoid the high costs associated with replacing their entire industrial control system prematurely.