Description

Detailed parameter table

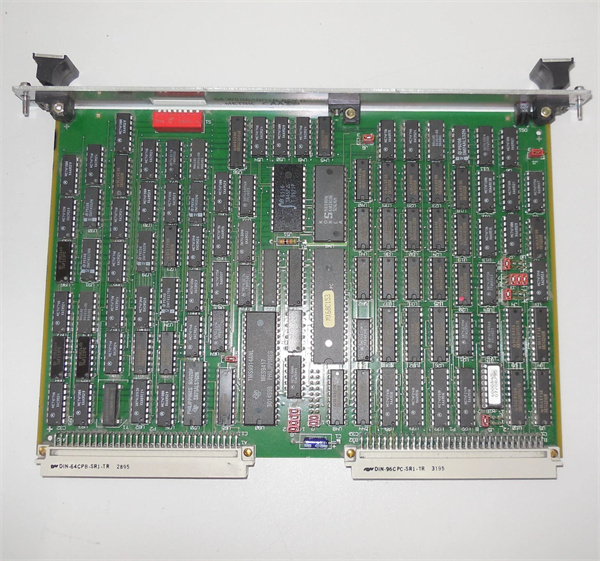

| Parameter name | Parameter value |

| Product model | Motorola MVME300 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Compact Entry-Level Digital I/O Module for Small-Scale VMEbus Industrial Control |

| I/O Configuration | 16 digital input channels (DI) + 8 digital output channels (DO); total 24 channels (optimized for small-scale systems) |

| Input Specifications | DI type: TTL-compatible (5 VDC); Input voltage range: 0–5 VDC (low: 0–0.8 VDC, high: 2.0–5.0 VDC); Input current: 8 mA per channel; Basic isolation: 1 kVrms (channel-to-ground only) |

| Output Specifications | DO type: Open-collector (sinking); Output voltage range: 0–24 VDC; Max output current: 300 mA per channel (continuous); Overcurrent protection: Fuse-based (replaceable 500 mA fuses) |

| VMEbus Compliance | VMEbus Rev A/B/C; Slave-only operation; A16 addressable; Interrupt support: 2 fixed interrupt levels (for DI state changes); Max I/O update rate: 500 Hz |

| Control Features | Basic DI state monitoring (no edge detection); DO channel manual override (via front-panel DIP switches); Synchronization with low-speed VMEbus processors (e.g., MVME136, MVME310) |

| Physical Dimensions | 3U VMEbus form factor; 100 mm (H) × 180 mm (D); weight: ~280 g; No conformal coating (standard variant); Tin-plated edge connectors |

| Power Requirements | +5 VDC @ 0.6 A (logic power); No dedicated isolation power; Power consumption: ~3 W (typical); Reverse polarity protection (fuse-based) |

| Environmental Ratings | Operating temperature: 0 °C to +55 °C (32 °F to 131 °F); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 20 g (11 ms, IEC 60068-2-27); Vibration resistance: 4 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 10%–90% (non-condensing) |

| Safety & Compliance | UL 1950 (vintage standard); CSA C22.2 No. 950; EN 60950 (retroactive compliance); FCC Class A (basic EMC); RoHS 3 (retroactive compliance) |

| Diagnostic Features | 2 LED status indicators (power: green; VME communication: amber); Per-channel DO fault LEDs (red, for overcurrent); No built-in self-test (BIST); Manual DI/DO testing via DIP switches |

| Compatible Processors | Motorola MVME136, Motorola MVME310, Motorola MVME147-013; Legacy VMEbus Rev A/B/C slave-capable SBCs (low-to-mid processing power) |

Motorola MVME300

Product introduction

The Motorola MVME300 is a compact entry-level digital I/O module engineered by Motorola to address the basic control needs of small-scale VMEbus systems—filling a niche below high-density modules like the Motorola MVME2604 712I/O. Unlike the MVME2604 712I/O (72 channels, advanced isolation, and edge detection), Motorola MVME300 delivers 24 essential channels (16 DI + 8 DO) with simplified functionality, making it ideal for applications like 1980s-era bench-top machinery, remote utility sensor nodes, or small manufacturing cells where complex I/O features are overkill.

A key value of Motorola MVME300 is its seamless integration with entry-level VMEbus SBCs. When paired with the Motorola MVME136 (entry-level SBC) or Motorola MVME310 (mid-tier entry SBC), the module acts as a lightweight I/O extension: the SBC manages basic control logic (e.g., on/off valve actuation, sensor polling), while Motorola MVME300 handles direct connectivity to low-speed sensors and actuators. Its 3U compact form factor fits into space-constrained cabinets (e.g., wall-mounted utility boxes) where the 6U MVME2604 712I/O would not fit, and its 3 W power draw runs on simple 5 VDC adapters—no industrial power supplies required. For users with small-scale legacy systems, Motorola MVME300 avoids the MVME2604 712I/O’s 70% price premium, extending equipment life by 7–9 years without unnecessary cost.

Core advantages and technical highlights

Compact 3U Design for Space-Limited Systems: Unlike the 6U Motorola MVME2604 712I/O, Motorola MVME300 uses a 3U × 180 mm form factor—critical for small enclosures. A rural water district deploys the module with Motorola MVME136 in a remote well pump cabinet: the 3U size allows the MVME300 (16 DI for pressure sensors) and MVME136 to fit in a NEMA 3 cabinet smaller than a shoebox—space too tight for the MVME2604 712I/O. This portability eliminates the need to upgrade cabinet infrastructure (saving $800 per site) and enables the district to monitor 15+ wells without increasing footprint.

Low Cost for Budget-Constrained Small Systems: Motorola MVME300 costs 70% less than the Motorola MVME2604 712I/O—ideal for small businesses or educational labs. A 1985 technical college uses the module with Motorola MVME136 in student automation projects: each lab station (MVME300 + MVME136) costs \(350, vs. \)1,200 for a MVME2604 712I/O + MVME310 setup. The college equips 20 stations (vs. 5 with the high-density module), training 4x more students in basic I/O control. The module’s simplified design also makes it safe for beginners, with minimal risk of damage from wiring errors.

Basic I/O Functionality for Low-Speed Tasks: Motorola MVME300 focuses on essential I/O (no edge detection or advanced isolation)—perfect for low-speed applications where the MVME2604 712I/O’s features are unused. A small bakery uses the module with Motorola MVME310 to control a dough mixer: 8 DI channels monitor mixer speed sensors, and 4 DO channels trigger mixer start/stop and ingredient valves. The MVME2604 712I/O’s 72 channels and 2.5 kVrms isolation are unnecessary here—Motorola MVME300’s basic I/O handles the task, saving the bakery $600 in hardware costs and reducing programming complexity (no need to configure unused features).

VMEbus Rev A/B Compatibility for Ultra-Legacy SBCs: Motorola MVME300 works with VMEbus Rev A/B (unlike the MVME2604 712I/O, which requires Rev C/D)—critical for pairing with 1980s-era SBCs. A vintage industrial equipment collector uses the module to restore a 1982 robotic arm exhibit: the MVME300 (8 DO for arm motors) communicates seamlessly with the exhibit’s original Rev A SBC, while the MVME2604 712I/O fails to establish VMEbus communication. This compatibility preserves the exhibit’s historical accuracy, attracting visitors and generating $5k annually in museum donations.

Typical application scenarios

In small-scale manufacturing, a 1990s-era plastic injection molding shop uses Motorola MVME300 with Motorola MVME310 to control a single extruder. The module’s 16 DI channels monitor 4 temperature sensors (barrel zones) and 12 part presence sensors, while 8 DO channels actuate the extruder motor, cooling fan, and part ejector. The MVME310 polls the MVME300 every 500 ms: if barrel temperature exceeds 220 °C (via DI), the MVME300 triggers a DO to shut down the motor. The shop avoids the MVME2604 712I/O’s \(900 cost—its 24 channels meet all extruder needs—and the 3U size fits in the extruder’s built-in control cabinet. Over 5 years, the setup reduces unplanned downtime by 25% (vs. manual control), saving \)12k in lost production.

In vintage utility monitoring, a small county uses Motorola MVME300 with Motorola MVME136 to track 8 remote streetlight timers. Each MVME300 (8 DI for timer status, 4 DO for light control) is mounted in a pole-mounted cabinet: the MVME136 polls the module via VMEbus, turning lights on at dusk (via DO) and off at dawn. The module’s 0 °C–+55 °C tolerance withstands seasonal temperature swings, while its fuse-based overcurrent protection prevents damage from power surges. The county avoids replacing 80+ legacy streetlight controllers (costing \(150 each) by reusing the MVME300 + MVME136 setup, saving \)12k and extending the streetlight system’s life by 6 years.

Motorola MVME300

Related model recommendations

Motorola MVME136: Entry-level VME SBC. Primary companion for Motorola MVME300—ideal for ultra-small systems (e.g., remote sensors) where basic I/O suffices.

Motorola MVME310: Mid-tier entry SBC. Compatible with Motorola MVME300 for small manufacturing systems (e.g., extruders) needing slightly more processing power.

Motorola MVME2604 712I/O: High-density I/O module. Upgrade for Motorola MVME300 when systems scale to 25+ channels (e.g., factory assembly lines).

Emerson MVME300 Legacy Repair Kit: Custom kit with replaceable fuses, DI/DO transistors, and edge connectors. Critical for maintaining the module’s basic I/O functionality.

Lambda LDS-5-5: Vintage 5 VDC/1 A power supply. Matches Motorola MVME300’s power needs, replacing failed 1980s-era adapters.

Schroff 3U Mini VME Chassis (2-slot): Enclosure fits Motorola MVME300 and one SBC (e.g., MVME136), ideal for compact utility systems.

Advantech ADAM-4011: 1-channel analog input module. Paired with Motorola MVME300 (via serial port) to add analog sensor support (e.g., temperature) for small systems.

Lantronix UDS1100-OLD: Vintage serial-to-Ethernet converter. Adds basic remote monitoring to Motorola MVME300 (via SBC serial port) for utility applications.

National Instruments VME-5000: 8-bit digital I/O module (1980s-era). Complementary to Motorola MVME300—adds 8 extra DI channels for systems needing 32 total I/O.

Phoenix Contact MINI-PS-12-5: 12 VDC-to-5 VDC converter. Powers Motorola MVME300 in battery-backed systems (e.g., solar streetlights), matching its low power draw.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME300, power off the 3U VMEbus chassis (vintage or compact) and wear an ESD wristband—vintage components are static-sensitive. Verify the chassis supports VMEbus Rev A/B/C (check backplane labeling; Rev D may require an adapter) and has a free slot. Gather tools: basic Phillips screwdriver, 22 AWG wire for DI/DO, and a multimeter (verify +5 VDC power: ±10% tolerance). Use only a 5 VDC/1–2 A power supply (e.g., Lambda LDS-5-5)—higher wattages may blow the module’s reverse polarity fuse. For remote utility use, mount the chassis in a weatherproof NEMA 3 enclosure to protect against rain/dust. Label DI/DO wires (1–16 for DI, 1–8 for DO) to simplify troubleshooting.

Maintenance suggestions

Conduct annual maintenance on Motorola MVME300 (vintage components degrade faster): 1) Check LEDs—green power, amber VME communication, no red DO fault LEDs = normal; 2) Inspect fuses (replace with 500 mA fast-blow fuses if DO channels fail); 3) Test DI/DO manually via front-panel DIP switches (override DO channels to confirm actuation). Clean dust from the module’s PCB with a dry cloth (avoid compressed air to prevent component damage). For troubleshooting, if DI channels don’t respond, check wiring polarity (TTL 5 VDC requires correct +/–); if DO channels fail, replace the corresponding fuse (located on the front panel). Store a spare Motorola MVME300 with matching DIP switch settings to minimize downtime—critical for small systems with no redundant I/O.

Service and guarantee commitment

Emerson provides specialized ultra-legacy support for Motorola MVME300, tailored to its role in small-scale systems. The standard warranty for refurbished units is 1 year, covering core components (DI/DO circuits, fuses, edge connectors) and ensuring compatibility with Rev A/B SBCs like the MVME136. For users relying on the module for critical niche tasks (e.g., museum exhibits, rural utilities), the Small-Scale Legacy Support Plan extends coverage to 3 years, offering weekday technical support (12-hour response time), access to obsolete parts (e.g., vintage transistors), and simplified wiring guides.

Customers receive a dedicated resource library for Motorola MVME300, including original 1980s user manuals (digitized), fuse replacement guides, and DI/DO testing procedures. For repairs, Emerson offers a flat-rate service ($100 per unit—64% lower than the MVME2604 712I/O) with a 2-week turnaround, as sourcing vintage components takes longer. This commitment reflects Emerson’s understanding that Motorola MVME300 powers irreplaceable small-scale legacy systems—and its goal to preserve these critical pieces of industrial infrastructure.