Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

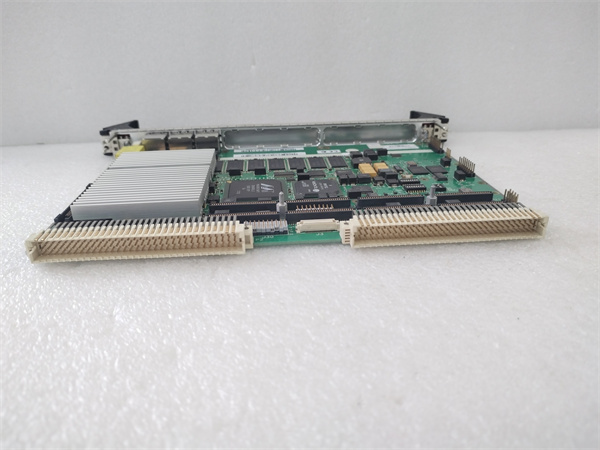

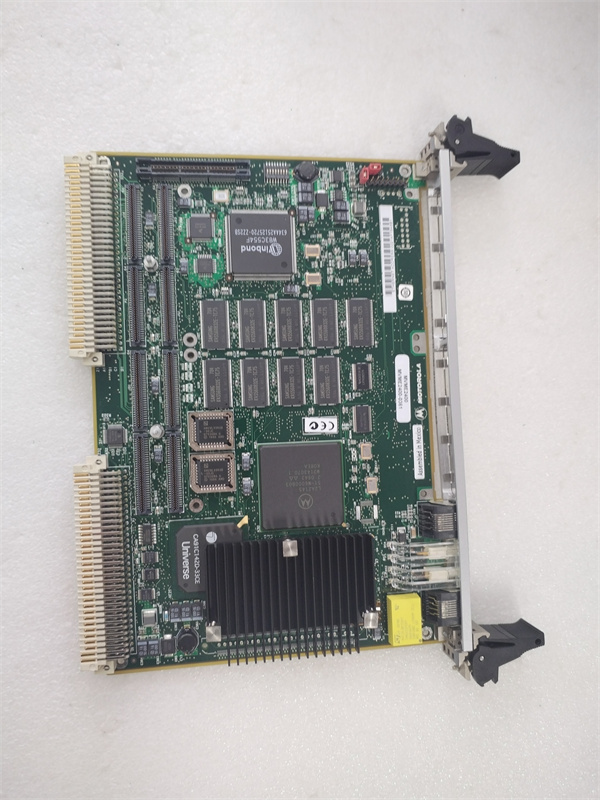

| Product Model | Motorola MVME 2400 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Single Board Computer |

| Processor | Motorola MPC860T PowerQUICC II (with an integrated 603e core) |

| Clock Speed | 66 MHz |

| Memory | Up to 64 MB of SDRAM; 2 MB of Flash memory (for code storage and data retention) |

| Storage | Optional CompactFlash socket for additional storage expansion (up to 1GB in some configurations) |

| Expansion Slots | 2 IEEE 1386.1 compliant 32 – bit PMC slots; 2 32 – bit PC•MIP expansion slots (both type II with front panel I/O) |

| Input/Output Interfaces | Dual 10/100 Mb/s Ethernet ports with auto – negotiation; multiple RS – 232/RS – 422/RS – 485 serial ports; CAN bus interface (for some models); USB 1.1 interface (in later revisions) |

| Bus Standard | VMEbus – compliant; also features an on – chip PCI interface (as part of the MPC860T’s capabilities) |

| Physical Dimensions | Approximately 8.5 inches by 9.5 inches, conforming to standard VME form factor |

| Power Requirements | 24 VDC (nominal); input voltage range: 18 – 36 VDC |

| Operating Temperature Range | – 20°C – + 70°C |

| Product Status | Obsolete (discontinued by manufacturer; available through aftermarket and refurbished sources) |

| Compliance Standards | CE, UL, RoHS; meets relevant industrial standards for electrical safety and electromagnetic compatibility |

| Compatibility | Compatible with a wide range of VME – based systems; PCI interface allows for integration with PCI – compliant peripherals |

| On – Board Features | Battery – backed real – time clock; 16 k x 8 NVRAM; multiple timers (including a watchdog timer); status LEDs for system monitoring |

MOTOROLA MVME2400

Product Introduction

The Motorola MVME 2400 is a powerful VMEbus single board computer designed to meet the demands of industrial and embedded computing applications. It combines high – performance processing with a rich set of connectivity options and expansion capabilities, making it a versatile solution for a wide range of industries.

Powered by the Motorola MPC860T PowerQUICC II processor, the MVME 2400 offers a balance of computational power and integrated communication functions. The 603e core within the MPC860T provides efficient processing for running complex software applications, while the integrated communication controllers enable seamless connectivity to various industrial devices and networks.

Core Advantages and Technical Highlights

High – Performance Processing

The MVME 2400’s MPC860T processor, running at 66 MHz, is capable of handling multitasking operations and complex algorithms with relative ease. This makes it suitable for applications such as real – time data processing in industrial automation, where it can analyze data from multiple sensors simultaneously and make quick decisions. For example, in a manufacturing plant, it can process data from temperature, pressure, and vibration sensors to monitor the health of machinery and predict potential failures.

Versatile Connectivity

With dual 10/100 Mb/s Ethernet ports, the MVME 2400 can be easily integrated into industrial networks. It can communicate with other devices on the factory floor, send data to a central control system, or even be accessed remotely for monitoring and control. The multiple serial ports (RS – 232/RS – 422/RS – 485) allow for connection to legacy devices, such as older sensors, actuators, and HMIs. The addition of a CAN bus interface in some models makes it ideal for applications in the automotive and industrial vehicle sectors, where CAN bus is widely used for in – vehicle networking. In later revisions, the inclusion of a USB 1.1 interface provides additional flexibility for connecting peripheral devices.

Robust Design for Industrial Use

The MVME 2400 is designed to operate in industrial environments. With an operating temperature range of – 20°C to + 70°C, it can withstand the temperature variations commonly found in factories, warehouses, and outdoor industrial installations. The board is built with high – quality components and has undergone extensive testing to ensure it can resist vibrations, shocks, and electrical interference. The power supply design is also optimized to handle voltage fluctuations within the specified input range, ensuring reliable operation.

Modular Expansion Capabilities

Featuring 2 IEEE 1386.1 compliant 32 – bit PMC slots and 2 32 – bit PC•MIP expansion slots, the MVME 2400 offers significant room for customization. The PMC slots can be used to add specialized functionality, such as high – speed data acquisition cards, advanced communication modules, or signal processing cards. The PC•MIP expansion slots, on the other hand, allow for the integration of additional I/O interfaces, enabling the connection of more sensors, actuators, or other industrial devices.

Typical Application Scenarios

Industrial Automation in Smart Factories

In smart factory settings, the MVME 2400 plays a crucial role in the automation infrastructure. It can act as a local controller, connecting to various sensors and actuators on the factory floor. The Ethernet ports are used to communicate with other devices in the network, such as programmable logic controllers (PLCs), robots, and higher – level control systems. The serial ports can be used to interface with older – generation devices, ensuring compatibility with existing equipment. The modular expansion slots can be used to add custom I/O cards, allowing for the control of unique manufacturing processes or the integration of new sensors.

Transportation and Logistics

In transportation and logistics applications, the MVME 2400 can be used in vehicle – mounted computing systems. The CAN bus interface enables seamless communication with other vehicle systems, such as engines, brakes, and sensors. The Ethernet ports can be used to connect to external networks, allowing for real – time tracking, data logging, and communication with a central dispatch system. The on – board memory and storage capabilities are sufficient for storing route data, vehicle diagnostic information, and other relevant data.

Building Automation

For building automation systems, the MVME 2400 can be used to control and monitor various building functions. It can connect to sensors for temperature, humidity, light levels, and occupancy, and then control actuators such as HVAC systems, lighting fixtures, and security systems. The multiple communication interfaces allow for easy integration with other building management systems, and the expansion slots can be used to add additional I/O channels as the building’s requirements grow.

Related Model Recommendations

Motorola MVME2100: While the MVME2100 has different processor options, it can be used in combination with the MVME 2400 in some scenarios. For example, the MVME2100 can handle basic I/O functions and data acquisition in a distributed control system, while the MVME 2400 can focus on more complex data processing and high – speed communication tasks.

Motorola FAB 0340 – 1049: This power supply module is suitable for providing stable power to the MVME 2400. Its voltage regulation and power output characteristics are well – matched to the requirements of the MVME 2400, ensuring reliable operation even in the presence of power fluctuations in industrial environments.

MVME – 162 – 020A: The advanced basic digital I/O module can be integrated with the MVME 2400 to expand its digital I/O capabilities. In applications where a large number of digital sensors and actuators need to be controlled, such as in a large – scale lighting control system or a complex industrial process with numerous on – off valves, this module can be used in tandem with the MVME 2400.

Belkin IEEE 1284 Parallel Cable: Although the MVME 2400 does not have a parallel port as a standard feature, in some custom – configured setups where an old – fashioned parallel – connected device needs to be integrated, this cable can be used in combination with an appropriate parallel – to – serial or parallel – to – USB converter to interface with the MVME 2400.

Emerson RSTi – EP Serial/Ethernet Gateway: If a system using the MVME 2400 needs to transition from a serial – based communication infrastructure to an Ethernet – based one, this gateway can be used. It bridges the gap between the MVME 2400’s serial interfaces and an Ethernet network, enabling the integration of legacy serial – based devices into a modern networked control system.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the MVME 2400, power off the VME chassis and disconnect all power sources to prevent electrical accidents. Ensure that the VME chassis has an available slot that is compatible with the MVME 2400’s form factor and bus interface. Use an anti – static wristband and mat to protect the sensitive components of the module from electrostatic discharge (ESD). Gather the necessary tools, including a screwdriver for chassis mounting, appropriate cables for connecting to external devices (twisted – pair cables for serial connections, Ethernet cables for network connections, and CAN bus cables if applicable), a torque wrench (with the correct torque settings for terminal connections), and a multimeter to test signal levels. Avoid installing the module near high – EMI sources, such as large motors or power supplies, to prevent signal interference.

Commissioning and Maintenance

For commissioning, carefully insert the MVME 2400 into the VME slot and secure it firmly. Connect the Ethernet cables to the network ports, following the proper wiring standards. Connect the serial devices to the appropriate RS – 232, RS – 422, or RS – 485 ports, ensuring correct pin – outs. If using a CAN bus interface, connect the CAN bus cables. Power on the system and check the status LEDs on the MVME 2400. The power LED should indicate that the module is receiving power. Ethernet link LEDs should light up when a network connection is established, and serial port TX/RX LEDs should blink when data is being transmitted or received. Use the appropriate software on a connected host system to configure the module’s settings, such as network IP addresses, serial baud rates, and CAN bus parameters. Test the communication by sending test data to connected devices and verifying the receipt of data.

For maintenance, regularly inspect the wiring connections, tightening any loose terminals and replacing damaged cables. Clean the module periodically using compressed air (at low pressure) to remove dust from the VME connector and other components. Check the integrity of the Ethernet port’s surge protection (if available) at regular intervals using an ESD simulator. If there are issues with the serial or CAN bus interfaces, ensure that the drivers are up – to – date and that the communication settings are correct. In models with expansion slots, periodically check for any loose expansion cards and reseat them if necessary. When upgrading the module, make sure to back up any important configuration data and replicate the settings on the new module to avoid disruptions to the connected systems.

Service and Guarantee Commitment

Although the Motorola MVME 2400 is an obsolete product, we offer a 90 – day warranty on all refurbished units. This warranty covers defects in processing performance, connectivity functionality (Ethernet, serial, CAN bus, USB as applicable), and any on – board features such as status LEDs and timers. Each refurbished module undergoes comprehensive testing, including 24 – hour continuous operation to ensure stable performance, communication tests across all interfaces to verify data transfer accuracy, and checks for any hardware – related issues.

Our technical support team is available 24/7 to provide assistance with installation, configuration, and troubleshooting. We offer customized maintenance plans, which may include quarterly remote performance checks, semi – annual on – site inspections, and software updates (where applicable). Our spare parts inventory includes critical components such as processors, memory modules, and interface controllers, ensuring fast repairs and minimizing downtime for systems using the MVME 2400.

For users looking to modernize their systems, we provide free consultation on alternative solutions, such as migrating to more modern Ethernet – based single board computers or industrial controllers, while still leveraging the existing infrastructure and software as much as possible.