Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME162PA-344E |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Enhanced Analog Input Module (16-channel, high-precision signal acquisition) |

| Input Channel Configuration | 16 differential analog input channels (software-configurable for single-ended use) |

| Input Signal Range | ±5 VDC, ±10 VDC, ±2.5 VDC (software-selectable per channel); unipolar 0–5 VDC, 0–10 VDC, 0–2.5 VDC |

| Resolution | 14-bit analog-to-digital converter (ADC); 0.006% full-scale accuracy (typical) – 4x higher precision than MVME162PA-344 |

| Sampling Rate | Up to 200 kSPS (aggregate); 12.5 kSPS per channel (sequential sampling); 50 kSPS per channel (burst mode) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 32-bit address/data bus; master/slave dual-mode support |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.5 A typical, 2.0 A maximum); +12 VDC (0.4 A typical); -12 VDC (0.4 A typical); passive heat dissipation (no fan) |

| Signal Isolation | Channel-to-channel isolation (500 Vrms); module-to-bus isolation (1000 Vrms) – double the isolation of MVME162PA-344 |

| Calibration | On-board precision voltage reference (±0.001% stability); software-calibratable with temperature compensation (0°C–60°C) |

| Operating Temperature Range | -10°C – 70°C (-14°F – 158°F) (extended industrial temperature tolerance) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; IEEE 1284 (optional parallel interface); FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-4 (enhanced EMC immunity) |

| On-Board Features | Programmable gain (1x, 2x, 4x, 8x, 16x); built-in self-test (BIST) for ADC validation; status LEDs for power, channel activity, and calibration |

| Compatibility | Optimized for Motorola VME SBCs (Motorola MVME172-263/260, Motorola MVME188A); works with power modules (Motorola FAB 0340-1049, Motorola 30-W2960B01A) and communication modules (Motorola MVME712/M) |

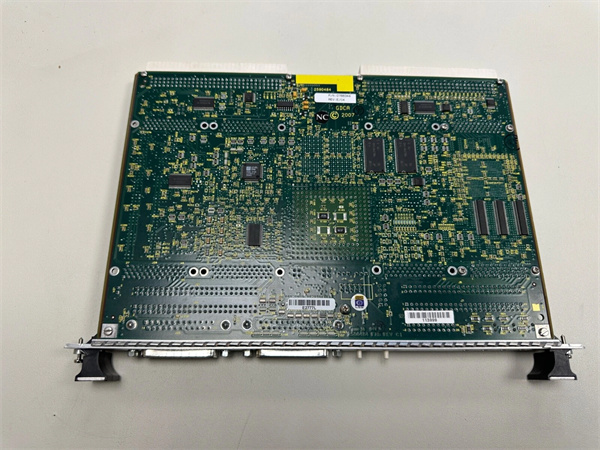

MOTOROLA MVME162PA-344E

Product Introduction

The Motorola MVME162PA-344E is an enhanced 16-channel analog input module, representing an upgraded variant of the MVME162PA series—engineered to deliver high-precision signal acquisition for mission-critical VMEbus automation systems. As a 3U VME form factor device, it builds on the foundational capabilities of the Motorola MVME162PA-344 by integrating a 14-bit ADC (vs. 12-bit) and doubled isolation levels, making it ideal for applications where nanoscale signal accuracy and robust noise immunity are non-negotiable.

A defining advancement of the Motorola MVME162PA-344E is its seamless integration with the broader Motorola VME ecosystem. When paired with a host SBC like the Motorola MVME172-263/260, it leverages the VMEbus’s 32-bit data path to transmit high-volume, high-precision sensor data (e.g., microvolt-level temperature fluctuations) without bottlenecks. It draws stable power from modules like the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, while its extended temperature range (-10°C–70°C) ensures reliability in extreme industrial environments—from freezing cold storage facilities to hot steel mills.

Whether deployed in semiconductor manufacturing, aerospace test benches, or medical device calibration systems, the Motorola MVME162PA-344E acts as the “precision data backbone” of VME setups. Its temperature-compensated calibration and built-in self-test (BIST) minimize drift and simplify maintenance, ensuring long-term accuracy that the standard Motorola MVME162PA-344 cannot match. These features make it an indispensable upgrade for legacy systems requiring enhanced measurement capabilities.

Core Advantages and Technical Highlights

14-Bit ADC with Industry-Leading Precision

The Motorola MVME162PA-344E’s 14-bit ADC delivers 0.006% full-scale accuracy—4x more precise than the 12-bit Motorola MVME162PA-344. This level of precision is critical for applications like semiconductor wafer testing, where measuring 10 mV voltage variations in a 5 V signal (0.2% of full scale) requires sub-millivolt resolution. The module’s programmable gain (up to 16x) further amplifies weak signals (e.g., 1 mV from a strain gauge), allowing it to detect anomalies that would go unnoticed by lower-precision modules. For example, in aerospace engine testing, the Motorola MVME162PA-344E can measure 5 mV fluctuations in fuel pressure—enabling engineers to identify early signs of pump wear before catastrophic failure.

Doubled Isolation for Extreme Noise Immunity

With 500 Vrms channel-to-channel isolation and 1000 Vrms module-to-bus isolation (double the Motorola MVME162PA-344’s specs), the Motorola MVME162PA-344E eliminates ground loops and cross-talk in high-voltage industrial environments. In a power plant’s turbine control system, where input sensors are powered by 480 VAC and the VMEbus operates at 5 VDC, this isolation prevents voltage spikes from corrupting data—ensuring accurate measurement of steam temperature (±2.5 VDC signal) even during generator load changes. The module’s compliance with IEC 61000-6-4 (enhanced EMC immunity) further shields it from electromagnetic interference (EMI) from nearby transformers, making it suitable for use in heavy industrial settings.

Extended Temperature Range and Temperature-Compensated Calibration

Unlike the Motorola MVME162PA-344 (0°C–60°C), the Motorola MVME162PA-344E operates from -10°C to 70°C—expanding its use in extreme environments like cold-chain food processing (where temperatures drop to -5°C) or desert-based solar farms (where cabinet temperatures reach 65°C). Its temperature-compensated calibration adjusts the ADC’s output based on ambient temperature, minimizing drift (typically <0.001% per °C) that would degrade accuracy in uncompensated modules. For instance, in a medical device calibration lab, the module maintains ±0.005% accuracy across its entire temperature range—critical for validating the performance of precision thermometers and blood pressure monitors.

32-Bit VMEbus and High-Speed Sampling

The Motorola MVME162PA-344E supports 32-bit VMEbus communication (vs. 16-bit for some legacy analog modules), enabling high-speed data transfer (up to 40 MB/s) to host SBCs like the Motorola MVME172-263/260. This is essential for applications requiring high aggregate sampling rates—such as a battery testing system where 16 channels (each sampling at 12.5 kSPS) generate 200 kSPS of data. The module’s burst mode (50 kSPS per channel) further captures transient events (e.g., a 10 ms voltage spike in a lithium-ion battery charge cycle) that sequential sampling would miss. When paired with the Motorola MVME712/M communication module, this high-speed data can be transmitted to a SCADA system in real time, enabling immediate response to anomalies.

Typical Application Scenarios

The Motorola MVME162PA-344E excels in precision-critical industrial environments, often paired with SBCs like the Motorola MVME172-263/260 and communication modules like the Motorola MVME712/M. In semiconductor manufacturing, it monitors the etching process: 16 differential channels capture microvolt-level signals from plasma sensors (±2.5 VDC), measuring electron density with 14-bit precision. The module’s 500 Vrms channel isolation prevents cross-talk between sensors, ensuring uniform etching across the wafer. The Motorola MVME172-263/260 processes this data to adjust RF power, while the Motorola MVME712/M transmits results to a central MES system—critical for meeting nanometer-scale manufacturing tolerances.

In aerospace avionics testing, the Motorola MVME162PA-344E is integrated into a test bench for flight control systems. It measures 16 channels of sensor data: gyroscope outputs (±5 VDC), accelerometer signals (±10 VDC), and pressure transducer readings (0–5 VDC). Its 14-bit accuracy captures 0.1° changes in gyroscope orientation—essential for validating autopilot functionality—while its -10°C–70°C temperature range withstands the extreme conditions of altitude simulation chambers. The module’s BIST feature allows technicians to validate ADC performance between tests, ensuring compliance with aerospace safety standards (e.g., DO-160).

For medical imaging equipment (e.g., MRI machines), the Motorola MVME162PA-344E measures low-noise signals from gradient coils (±2.5 VDC). Its 1000 Vrms module isolation protects sensitive MRI electronics from high-voltage gradients, while its temperature-compensated calibration maintains accuracy as the MRI’s magnet heats up during operation. The Motorola MVME712/M transmits this data to a control workstation, where engineers adjust coil currents to optimize image resolution. In this scenario, the module’s precision directly impacts patient diagnosis—making it a superior choice to the standard Motorola MVME162PA-344.

MOTOROLA MVME162PA-344E

Related Model Recommendations

Motorola MVME162PA-344: Base analog input module. Predecessor to Motorola MVME162PA-344E; 12-bit ADC, 250 Vrms isolation. Suitable for non-precision applications (e.g., basic temperature monitoring) where cost is a priority.

Motorola MVME172-263/260: VME SBC. Host controller for Motorola MVME162PA-344E; processes 14-bit data and executes control logic—critical for leveraging the module’s precision.

Emerson MVME5500: Modern VME SBC. PowerPC-based replacement for Motorola MVME172-263/260; compatible with Motorola MVME162PA-344E and adds Ethernet/IP for transmitting high-precision data to cloud platforms.

Motorola MVME162-533A: Analog I/O module. Complements Motorola MVME162PA-344E in closed-loop systems; uses the module’s input data to generate analog outputs for controlling actuators (e.g., valves, pumps).

Motorola MVME712/M: VME communication module. Transmits Motorola MVME162PA-344E’s 14-bit data to SCADA/DCS systems via Ethernet/serial—enabling remote monitoring of precision processes.

Motorola FAB 0340-1049: Power supply module. Primary power source for Motorola MVME162PA-344E; delivers stable ±12 VDC for the module’s isolation circuits and +5 VDC for the ADC.

Emerson RSTi-EP AI Module: Ethernet-based analog input module. Modern alternative to Motorola MVME162PA-344E; 16-bit ADC and Ethernet connectivity for users migrating from VME to Ethernet systems.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola MVME162PA-344E, power off the VME chassis and disconnect the Motorola FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis has a 3U VME slot compatible with 32-bit modules and that the VME backplane can supply +5 VDC (2.0 A max), +12 VDC (0.4 A), and -12 VDC (0.4 A). Use an anti-static wristband and mat to protect the module’s 14-bit ADC from ESD damage—critical for maintaining precision. Gather tools: Phillips-head screwdriver (for chassis mounting), shielded twisted-pair cables (for input wiring), and a torque wrench (to tighten terminal screws to 0.5–0.8 N·m). Avoid installing near high-voltage equipment (e.g., MRI magnets) or heat sources (e.g., power resistors) to prevent EMI or thermal drift.

Commissioning and Maintenance

For commissioning, insert the Motorola MVME162PA-344E into the VME slot and secure it. Connect input sensors to the module’s terminals, using shielded cables for differential channels (minimizes noise). Power on the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, then check the module’s LEDs: green “POWER” confirms voltage; blinking “ACTIVITY” LEDs indicate data acquisition. Use the Motorola MVME172-263/260’s configuration software to set input ranges (e.g., ±2.5 VDC for strain gauges) and gain (e.g., 16x for weak signals). Run the BIST to validate ADC performance—ensure accuracy is within 0.006% of full scale. Calibrate the module using a precision voltage source (±0.001 V accuracy), enabling temperature compensation to correct for ambient conditions.

For maintenance: Perform monthly visual inspections to check for loose cables or damaged shields—repair immediately to avoid noise ingress. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector (prevents signal degradation). Re-calibrate semi-annually (or after temperature extremes) using the on-board reference—this maintains 14-bit precision by correcting for ADC drift. If the BIST fails, use the Motorola MVME172-263/260’s diagnostic tools to isolate the issue (e.g., a faulty channel) before replacing the module. When upgrading from Motorola MVME162PA-344, replicate the input wiring but reconfigure ranges/gain to leverage the Motorola MVME162PA-344E’s enhanced capabilities.

Service and Guarantee Commitment

Though Motorola MVME162PA-344E is obsolete, we offer a 120-day warranty on all refurbished units—40% longer than our warranty for Motorola MVME162PA-344—covering defects in ADC precision, isolation performance, and calibration stability. Each refurbished module undergoes rigorous testing: 72-hour burn-in at -10°C–70°C (validates temperature compensation), 14-bit accuracy checks (using NIST-traceable voltage sources), and isolation resistance testing (ensures 1000 Vrms module protection). This guarantees the module meets the original industrial-grade precision standards.

Our technical support team (24/7 availability) specializes in Motorola MVME162PA-344E calibration, BIST troubleshooting, and integration with VME SBCs like the Motorola MVME172-263/260. We offer customized precision maintenance plans: semi-annual on-site calibration (using portable precision analyzers) and remote BIST monitoring (via Motorola MVME712/M) to proactively detect accuracy issues. Our spare parts inventory includes critical high-precision components (e.g., 14-bit ADC chips, precision voltage references) for fast repairs—minimizing downtime in precision-critical applications.

For users modernizing to Ethernet systems, we provide free consultation to select Emerson RSTi-EP AI modules (16-bit precision