Description

Detailed parameter table

| Parameter name | Parameter value |

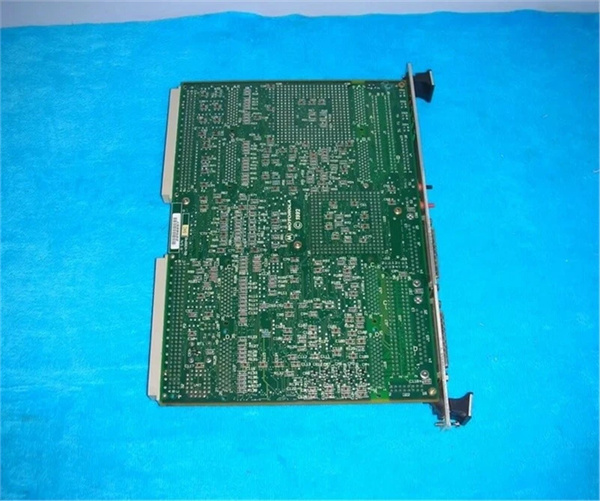

| Product model | Motorola MVME162 – 012 |

| Manufacturer | Motorola (now under Emerson’s industrial portfolio) |

| Product category | High – Performance VMEbus Embedded Controller for Advanced Industrial Automation |

| Processor | 25 MHz MC68LC040 enhanced 32 – bit microprocessor with 8 KB cache and MMU; optional 25 MHz MC68040 32 – bit microprocessor with 8 KB cache, MMU, and FPU |

| Memory | 4 MB of shared DRAM (expandable to 16 MB); 512 KB SRAM with battery backup; 1 MB of flash memory for on – board monitor/debugger or user – installed firmware; 8K x 8 NVRAM and clock with battery backup |

| VMEbus interface | A32/D64 VMEbus master/slave interface with system controller functionality; high – performance DMA support for VMEbus D64 and local bus memory burst cycles |

| I/O interfaces | Two serial communication ports (console port as EIA – 232 – D DTE, second port user – configurable for EIA – 232 – D/EIA – 422 (V.36) DTE/DCE); four 16 – or 32 – bit Industry Pack® ports (one DMA channel per port) |

| Optional interfaces | SCSI bus interface with 32 – bit local bus burst DMA; Ethernet transceiver interface with 32 – bit local bus DMA |

| Timers | Six 32 – bit timers (four without VMEbus) and watchdog timer |

| Physical dimensions | 6U VMEbus form factor; occupies a single VME slot |

| Power requirements | +5 VDC (±5%), 3.5 A typical, 4.5 A maximum (with PROM); environmental operating temperature: 0 °C to 70 °C |

| Diagnostic features | On – board debugger and diagnostic firmware; four – stage requester, seven – stage interrupter, and seven – stage interrupt handler for VMEbus; remote reset/abort/status control functions |

Motorola MVME162-012

Product introduction

The Motorola MVME162 – 012 is a high – performance VMEbus embedded controller designed to meet the complex demands of advanced industrial automation systems. It belongs to Motorola’s esteemed lineup of industrial control products, offering a powerful combination of processing capabilities and versatile interfaces.

Equipped with either a 25 MHz MC68LC040 enhanced 32 – bit microprocessor (with 8 KB cache and MMU) or an optional 25 MHz MC68040 32 – bit microprocessor (featuring cache, MMU, and FPU), the MVME162 – 012 can handle a wide range of computational tasks. Its A32/D64 VMEbus master/slave interface, along with system controller functionality, allows seamless integration into VME – based systems. The controller also comes with a generous amount of memory, including expandable DRAM, SRAM with battery backup, and flash memory for storing crucial firmware. In the industrial automation landscape, the Motorola MVME162 – 012 serves as a reliable core component, enabling efficient data processing, real – time control, and communication between various industrial devices.

Core advantages and technical highlights

High – performance processing

The availability of different microprocessor options in the Motorola MVME162 – 012 allows users to tailor the controller to their specific application needs. The MC68040 variant, with its FPU, is ideal for applications that require complex mathematical calculations, such as in advanced motion control systems. In a robotic manufacturing cell, the MVME162 – 012 with an MC68040 can precisely calculate the trajectories of robotic arms, ensuring accurate and efficient part handling.

Versatile I/O capabilities

With two serial communication ports and four Industry Pack® ports, the MVME162 – 012 can interface with a plethora of industrial devices. The serial ports can be used to connect to sensors, HMIs, or other serial – based devices, while the Industry Pack® ports offer a 32 – bit data path for modules that provide various I/O, control, and interface functions. In a chemical plant, the MVME162 – 012 can use its serial ports to communicate with temperature and pressure sensors, and the Industry Pack® ports to connect to modules that control valves and pumps.

Memory flexibility

The expandable DRAM (from 4 MB to 16 MB) and the presence of SRAM with battery backup and flash memory provide the MVME162 – 012 with excellent memory flexibility. The SRAM backup ensures that critical data is not lost during power outages, while the flash memory can store the on – board monitor/debugger or user – installed firmware. In a power generation facility, the MVME162 – 012 can use its memory to store historical data from power sensors, which can be used for predictive maintenance and performance optimization.

Typical application scenarios

Industrial manufacturing

In automotive manufacturing plants, the Motorola MVME162 – 012 can be used to control robotic assembly lines. Its high – performance processing capabilities enable it to manage the complex movements of robotic arms, ensuring precise part placement. The versatile I/O interfaces can connect to sensors that detect the presence of parts, and to actuators that control the movement of conveyor belts.

Process control

In a pharmaceutical production facility, the MVME162 – 012 can be employed to monitor and control the chemical reactions involved in drug synthesis. The serial ports can be used to receive data from temperature, pressure, and pH sensors, while the Industry Pack® ports can be used to control the valves and pumps that regulate the flow of reactants. The on – board debugger and diagnostic firmware are invaluable for quickly identifying and resolving any issues that may arise during the production process.

Transportation systems

In a subway control center, the MVME162 – 012 can be used to manage the signaling system. Its ability to handle real – time data and communicate with multiple devices makes it suitable for coordinating the movement of trains, ensuring safe and efficient transportation. The memory backup features ensure that critical system settings and data are retained during power disruptions.

Related model recommendations

Motorola MVME167 – 033A: A higher – end VMEbus SBC with a more powerful processor. It can be considered as an upgrade for applications that require even more processing power than the MVME162 – 012, such as large – scale data – intensive industrial control systems.

Motorola MVME147 – 013: A mid – range VMEbus SBC. It can be a cost – effective alternative to the MVME162 – 012 for applications that do not require the high – end features of the MVME162 – 012, but still need reliable VMEbus – based control.

Motorola MVME350: A VME I/O expansion module. It can be paired with the MVME162 – 012 to add more I/O capabilities, such as additional serial ports or digital I/O channels, for applications with extensive I/O requirements.

Motorola MVME320B: A serial expansion module. This module can be used in conjunction with the MVME162 – 012 to increase the number of serial communication ports, useful for systems that need to connect to a large number of serial – based devices.

Emerson MVME162 – 012 Legacy Repair Kit: Specifically designed for the MVME162 – 012, this kit contains essential components for repairing and maintaining the controller, ensuring its long – term reliable operation.

Motorola MVME162-012

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Motorola MVME162 – 012, ensure that the VMEbus chassis is powered off. Wear an ESD wristband to prevent electrostatic discharge damage to the sensitive components of the controller. Verify that the chassis has a compatible VMEbus slot and sufficient power supply to meet the MVME162 – 012‘s requirements. Gather the necessary tools, such as a screwdriver for securing the controller in the slot. If using optional interfaces like SCSI or Ethernet, ensure that the relevant cables and connectors are properly prepared.

Maintenance suggestions

Regularly check the LEDs on the MVME162 – 012 to monitor its status. The power LED should be steadily lit, and the activity LEDs can indicate normal data transfer. Periodically run the on – board diagnostic firmware to check for any hardware issues. In case of a malfunction, use the on – board debugger to identify the problem. If replacing components, such as the optional memory modules, ensure that they are compatible with the MVME162 – 012. Keep the controller in a clean and dust – free environment, and ensure proper ventilation to maintain the operating temperature within the specified range.

Service and guarantee commitment

Emerson, the current supporter of Motorola’s industrial products, offers a comprehensive service and guarantee for the Motorola MVME162 – 012. The standard warranty for refurbished units covers all major components, including the processor, memory, and interfaces, for a specified period. For customers with critical applications, Emerson provides an extended warranty option, along with 24/7 technical support. In case of any issues, Emerson’s technical team can quickly diagnose and provide solutions, either remotely or on – site if necessary. The company also ensures the availability of spare parts, including those for the optional features of the MVME162 – 012, to minimize downtime. This commitment reflects Emerson’s confidence in the quality and reliability of the Motorola MVME162 – 012 and its dedication to customer satisfaction.