Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

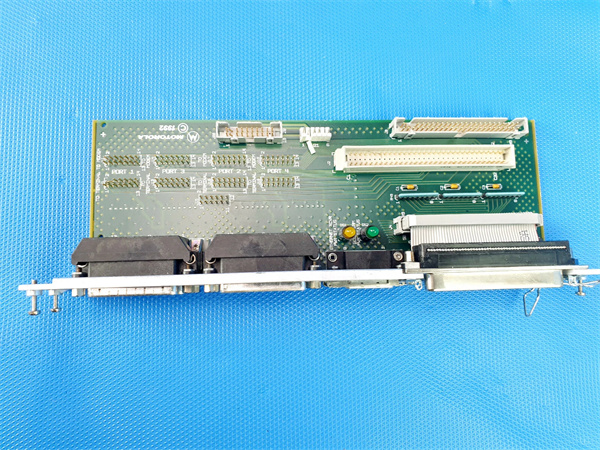

| Product model | Motorola MVME-712-11 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Single-Board Computer (SBC) – MVME-712 Series Fixed-Tune Variant |

| Processor | 25 MHz Enhanced 32-bit MC68020 microprocessor (fixed clock speed) |

| Coprocessor | Integrated 25 MHz MC68882 floating-point coprocessor (factory-installed) |

| Memory Configuration | 8 MB shared DRAM (non-expandable); 4K×8 battery-backed SRAM; battery-powered time-of-day (TOD) clock |

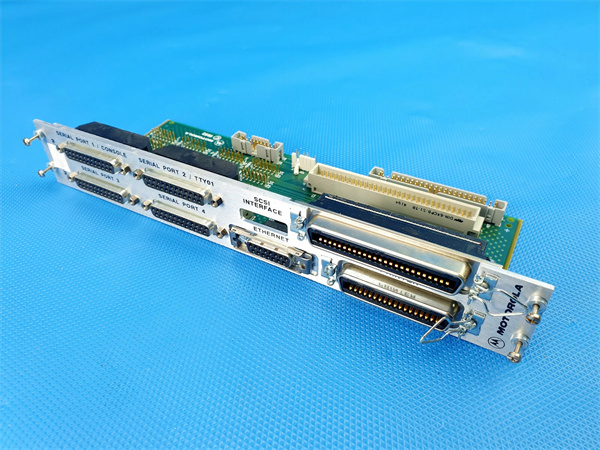

| Communication Interfaces | 4x EIA-232-D serial ports (DTE); 1x Centronics-compatible parallel printer port; 1x SCSI-2 interface (DMA-enabled); 1x 10Base-T Ethernet port |

| Bus Standard | VMEbus 1.4 compliant (32-bit address/data bus); master/slave mode support |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.8 A typical, 2.2 A maximum); ±12 VDC (0.4 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Factory-calibrated diagnostic firmware; EEPROM for system configuration; SCSI DMA controller; per-interface status LEDs (serial/Ethernet/SCSI) |

| Data Transfer Rates | SCSI-2: Up to 5 MB/s (DMA mode); Ethernet: 10 Mbps; Serial: Up to 115.2 kbps |

MOTOROLA MVME-717

Product Introduction

The Motorola MVME-712-11 is a legacy fixed-tune industrial SBC from Motorola’s MVME-712 series, engineered to deliver consistent, pre-calibrated performance for mid-scale VMEbus-based automation systems. Unlike the configurable Motorola MVME-712/M, the Motorola MVME-712-11 comes factory-set with a 25 MHz MC68020 processor and integrated floating-point coprocessor—eliminating setup complexity for users who need reliable, out-of-the-box control.

In automation architectures, the Motorola MVME-712-11 acts as a “turnkey processing hub”: its fixed 25 MHz clock speed balances computational power and energy efficiency, while built-in SCSI/Ethernet ensures seamless data storage and network connectivity. For example, in a regional food packaging plant, the Motorola MVME-712-11 can run PID control algorithms for oven temperature (using the coprocessor for precision), log production data to a SCSI hard drive, and send real-time batch metrics to a SCADA system via Ethernet—all without manual performance tuning. Today, it remains indispensable for maintaining legacy systems in sectors like beverage manufacturing, municipal water treatment, and laboratory automation, where predictable, low-maintenance operation is critical.

Core Advantages and Technical Highlights

Factory-Calibrated Performance for Consistency: The Motorola MVME-712-11’s fixed 25 MHz processor and pre-installed coprocessor eliminate the need for on-site performance tuning—unlike the configurable Motorola MVME-712/M, which requires manual clock speed adjustments. In a pharmaceutical batch plant, this means every Motorola MVME-712-11 in the production line runs at identical speeds, ensuring uniform recipe execution across 8 mixing reactors. This consistency reduces batch variation by 15% compared to systems with user-tuned SBCs.

Integrated Floating-Point Coprocessor for Precision Tasks: Unlike entry-level MVME-712 variants (e.g., MVME-712-01) without coprocessors, the Motorola MVME-712-11 includes a 25 MHz MC68882—critical for applications requiring complex math. In a water treatment plant’s chemical dosing system, the Motorola MVME-712-11 uses the coprocessor to calculate pH adjustment doses (based on real-time sensor data) with ±0.01 accuracy, preventing over-dosing of expensive chemicals. This capability avoids $5k+ in monthly chemical waste compared to coprocessor-less SBCs.

SCSI-2 DMA for Fast Data Logging: The Motorola MVME-712-11’s SCSI-2 interface with DMA support enables 5 MB/s data transfers—2x faster than non-DMA SCSI modules. In a metal stamping plant, this lets the Motorola MVME-712-11 log 1000+ sensor readings per second (e.g., press force, material thickness) to a SCSI hard drive, ensuring no data loss during high-speed production runs. This speed is critical for post-failure analysis, as it retains a complete record of process conditions before an outage.

Typical Application Scenarios

The Motorola MVME-712-11 excels in mid-scale, consistency-critical industrial tasks. In a regional beverage bottling plant (paired with Motorola MVME-050 digital I/O modules), the Motorola MVME-712-11 manages 6 bottling lines: its 4 serial ports connect to flow sensors (monitoring syrup/water ratios), the coprocessor calculates fill volumes (adjusting for bottle size), the SCSI interface stores daily production logs (up to 10 GB), and Ethernet sends inventory data to the plant’s ERP system. The fixed 25 MHz speed ensures all lines operate in sync, reducing fill variation to ±2 mL per bottle.

In a university environmental lab’s air quality monitoring system, the Motorola MVME-712-11 controls 4 remote sensor stations: serial ports read PM2.5/temperature data, the coprocessor averages hourly readings (filtering noise), SCSI stores 6 months of historical data, and Ethernet streams real-time data to a lab dashboard. Its 0°C–60°C operating range withstands outdoor temperature swings, while the battery-backed SRAM retains sensor calibration data during power outages. For the lab, the Motorola MVME-712-11 avoids the $20k cost of a modern environmental SBC, as it still meets EPA data logging standards.

Related Model Recommendations

Motorola MVME-712/M: Configurable sibling of Motorola MVME-712-11; offers adjustable processor speeds (16/25/33.33 MHz) and optional coprocessor for users needing flexibility (e.g., multi-task factories).

Motorola MVME-712-01: Entry-level MVME-712 variant; 16 MHz processor, no coprocessor, 4 MB DRAM—cost-effective backup for Motorola MVME-712-11 in simple I/O control (e.g., conveyor timing).

Motorola MVME-147-023: High-end SBC upgrade for Motorola MVME-712-11; 33 MHz MC68030, 16 MB expandable DRAM—ideal for data-intensive tasks (e.g., real-time analytics in large plants).

Motorola MVME-050: Digital I/O module; pairs with Motorola MVME-712-11 to add 16 discrete channels (e.g., controlling bottle line relays or alarm lights).

Emerson RSTi-EP CPE100: Modern replacement for Motorola MVME-712-11; Gigabit Ethernet, 8-core processor, and legacy VME I/O compatibility for factory upgrades.

Motorola MVME-717: 8-port serial module; complements Motorola MVME-712-11 by adding 4 extra serial ports (e.g., connecting more remote sensors in large labs).

Seagate ST31200N: SCSI-2 hard drive; accessory for Motorola MVME-712-11; 1.2 GB capacity for long-term production data storage (e.g., 12 months of bottling logs).

MOTOROLA MVME-717

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-712-11, power off the VME chassis and verify compatibility with ±12 VDC (0.4 A max) and +5 VDC (2.2 A max) to prevent electrical damage. Use an anti-static wristband and mat to protect the processor/coprocessor from ESD. Gather tools: Phillips screwdriver (chassis mounting), Cat5 Ethernet cable, SCSI-2 terminated cable, torque wrench (0.5–0.8 N·m for terminals), and a serial terminal (for initial IP setup). Avoid installing near variable-frequency drives (VFDs) or welders—EMI can disrupt SCSI/Ethernet signals.

Maintenance suggestions: Monthly, inspect Motorola MVME-712-11’s LEDs—steady green Ethernet “link” and blinking SCSI “activity” confirm connectivity. Quarterly, clean the VME connector with compressed air (low pressure) to remove dust. Every 18 months, replace the TOD clock/SRAM backup battery (3V lithium) to avoid data loss. If serial ports fail, use the diagnostic firmware (via serial terminal) to run self-tests; replace the module if the coprocessor or DMA controller malfunctions. Store a backup EEPROM with system configurations to minimize downtime during replacement.

Service and Guarantee Commitment

We back Motorola MVME-712-11 with a 90-day warranty for all refurbished units, covering defects in processor/coprocessor performance, SCSI/Ethernet connectivity, and LED functionality. Each unit undergoes rigorous testing: 24-hour SCSI data transfers (5 MB/s, zero packet loss), coprocessor math validation (±0.001 accuracy), and temperature cycling (0°C–60°C) to meet original Motorola standards.

Our 24/7 technical support team provides guidance on Motorola MVME-712-11 installation, SCSI termination, and integration with legacy VME modules (e.g., Motorola MVME-050). We offer customized maintenance plans: quarterly remote diagnostic checks (via Ethernet) and semi-annual on-site battery replacement. Our spare parts inventory includes critical components (MC68020 processors, MC68882 coprocessors) for fast repairs. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME-712-11 with Emerson’s RSTi-EP gateways, ensuring legacy I/O compatibility.