Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

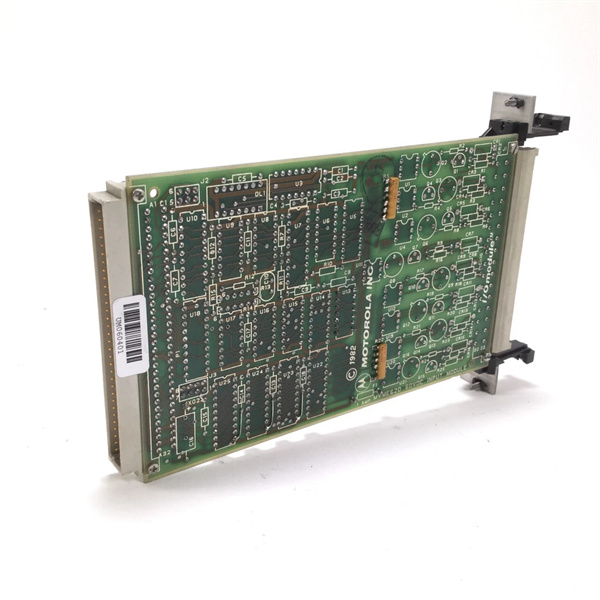

| Product Model | MVME-410 |

| Manufacturer | Motorola |

| Product Category | 3U VMEbus 68000-Series Single-Board Computer (SBC) |

| Processor | MC68040, 25 MHz (with FPU & MMU) |

| Memory Configuration | 4 MB DRAM, 1 MB EPROM, 64 KB SRAM |

| Communication Interfaces | 2 x RS-232C Ports, 1 x Centronics Parallel Port |

| Expansion Slots | 2 x Industry Pack (IP) Ports |

| VMEbus Interface | VMEchip1 Controller (Master/Slave, 32-bit Data Bus) |

| Form Factor | 3U Eurocard (Single-slot VME Standard) |

| Operating Temperature Range | -40°C to +85°C |

| Power Requirements | 5V DC ±5%, ±12V DC ±10% |

| Supported OS | VRTX, OS-9, pSOS |

| Timing Features | 4 x 16-bit Timers + Watchdog Timer |

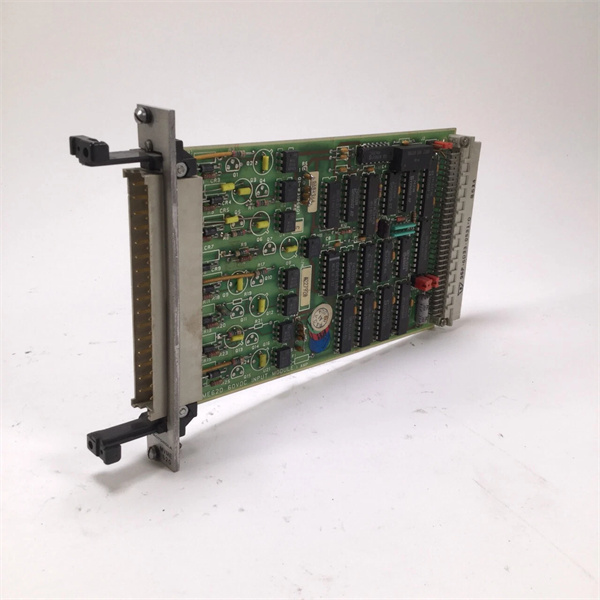

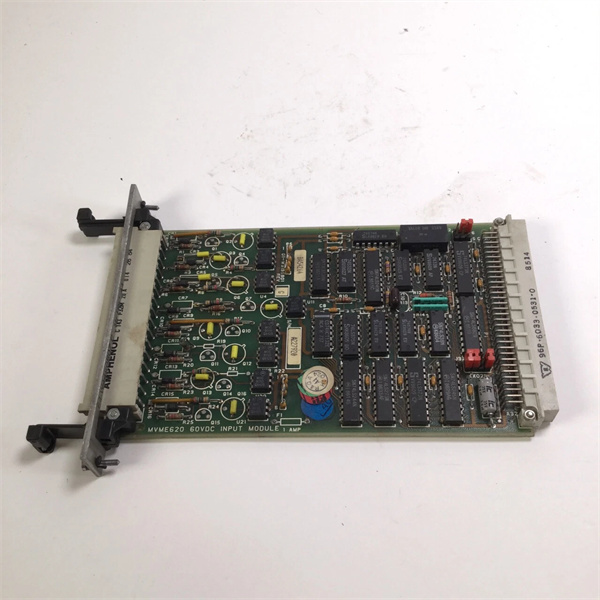

Motorola MVME-620

Product Introduction

The **Motorola MVME-410** is a robust 3U VMEbus Single-Board Computer (SBC) powered by the MC68040 processor, designed for legacy and mid-range industrial automation applications. As a classic model in Motorola’s MVME400 series, it combines proven 68000-series processing performance with essential I/O and expansion capabilities, serving as a reliable core control unit in established automation systems.

Equipped with 4 MB DRAM for data processing, 1 MB EPROM for firmware storage, and 64 KB SRAM for cache, the **Motorola MVME-410** ensures stable execution of real-time control algorithms. Its dual RS-232C ports enable serial connectivity with peripheral devices, while the Centronics parallel port supports printer or high-speed I/O connections. The two Industry Pack (IP) ports allow modular expansion for application-specific needs. With a wide operating temperature range of -40°C to +85°C and compliance with VMEbus standards, the **Motorola MVME-410** seamlessly integrates into harsh industrial environments and legacy VME ecosystems.

Core Advantages & Technical Highlights

Proven 68000-Series Performance: The 25 MHz MC68040 processor with FPU and MMU delivers reliable computational power optimized for legacy real-time control tasks. Its CISC architecture ensures compatibility with existing 68000-series software, enabling smooth operation of mature control algorithms without costly reprogramming—ideal for maintaining legacy automation systems.

Legacy-Friendly Connectivity: The dual RS-232C ports and Centronics parallel port provide seamless connectivity with legacy industrial peripherals such as CRT terminals, printers, and serial-based sensors. This eliminates the need for expensive protocol converters, simplifying integration into established systems.

Industrial-Grade Reliability: Designed to operate in -40°C to +85°C environments, the **Motorola MVME-410** withstands extreme temperatures, vibration, and electromagnetic interference (EMI) common in manufacturing plants, industrial machinery, and transportation systems. Its rugged mechanical design ensures long-term stable operation, minimizing unplanned downtime in critical legacy setups.

Modular Expansion Flexibility: Two Industry Pack ports allow addition of specialized I/O modules (e.g., analog I/O, digital I/O, communication cards), providing system scalability to adapt to evolving application needs without replacing the core SBC. This modularity extends the product’s lifecycle in dynamic industrial environments.

Robust VMEbus Integration: The VMEchip1 controller supports 32-bit VMEbus data transfers and functions as both master and slave, enabling efficient communication with other VMEbus modules (e.g., I/O cards, memory modules). This ensures backward compatibility with legacy VME systems, protecting significant infrastructure investments.

Typical Application Scenarios

Legacy Industrial Control: In semiconductor manufacturing equipment with established 68000-series control systems, the **Motorola MVME-410** serves as the main controller for wafer handling robots. Its MC68040 processor runs legacy motion control software, while RS-232C ports connect to position encoders and HMI terminals. The Industry Pack ports add analog I/O for process parameter monitoring, ensuring continued operation of critical production equipment.

Industrial Machinery Retrofit: In retrofitting older textile or paper mills, the **Motorola MVME-410** replaces obsolete controllers while maintaining compatibility with existing sensors and actuators. Its parallel port connects to legacy printers for production logs, and the RS-232C ports interface with motor drives. The rugged design withstands the dusty, vibration-prone environment of industrial mills.

Transportation Control Systems: In legacy railway signaling or maritime navigation systems, the **Motorola MVME-410** processes sensor data from track circuits or shipboard instruments. Its VMEbus interface integrates with existing communication modules, and the watchdog timer ensures system stability in remote, unmanned locations. The wide temperature range适应s outdoor or harsh on-board conditions.

Test & Measurement Equipment: In older aerospace or defense test rigs, the **Motorola MVME-410** controls data acquisition from strain gauges and pressure sensors. The Industry Pack ports add specialized signal conditioning modules, while the parallel port outputs test results to chart recorders. Its compatibility with legacy OS (e.g., VRTX) ensures continuity of test procedures developed over decades.

Motorola MVME-620

Related Model Recommendations

Motorola MVME-420: Higher-performance variant of **Motorola MVME-410** with 33 MHz MC68040 and expanded memory, ideal for upgrading legacy systems needing more processing power.

Motorola MVME-701A: Serial communication module compatible with **Motorola MVME-410**, adding RS-422/485 ports for long-distance serial connectivity.

Motorola MVME-162-01: 3U VMEbus CPU module complementary to **Motorola MVME-410** for distributed control systems with mixed 68000 and PowerPC nodes.

GE VMIVME-7650: Digital I/O Industry Pack module, used with **Motorola MVME-410** to add discrete input/output channels for legacy machinery control.

Motorola MVME-197LE: Memory expansion module for **Motorola MVME-410**, increasing DRAM capacity to 16 MB for running larger legacy applications.

Motorola MVME-605: Next-generation PowerPC SBC for upgrading **Motorola MVME-410** systems, with migration support for legacy software.

Installation & Maintenance Guidelines

Installation Preparation: Before installing the **Motorola MVME-410**, ensure the VMEbus chassis is powered off and properly grounded. Align the module with the 3U slot guides, verifying that the P1/P2 backplane connectors are correctly positioned. Gently insert the module until fully seated, then fasten the front-panel screws to prevent vibration-induced disconnections. For Industry Pack modules, insert them into the IP ports and secure with retaining clips. Route serial and parallel cables away from high-voltage lines to minimize EMI.

Maintenance Best Practices: Perform quarterly inspections to clean dust from the module’s connectors, heatsinks, and ventilation slots using compressed air. Regularly check the power supply voltages (5V ±5%, ±12V ±10%) to prevent component damage. Test the watchdog timer monthly by triggering a simulated fault and confirming the module resets properly. Back up the EPROM firmware and configuration data annually using compatible legacy programming tools. Use only genuine Motorola spare parts to maintain system compatibility and reliability with legacy VMEbus components.

Service & Warranty Commitment

The **Motorola MVME-410** is backed by a 2-year manufacturer’s warranty covering defects in materials and workmanship under normal industrial operation. Motorola’s technical support team provides specialized assistance for legacy systems via email and phone, with response times within 24 hours for critical issues. We offer remote diagnostic services for troubleshooting legacy software and hardware interactions, minimizing on-site service costs. For long-term legacy support, we provide EPROM reprogramming and component repair services to extend product lifecycle. Our commitment to quality ensures that the **Motorola MVME-410** continues to deliver consistent performance, protecting your investment in established industrial automation infrastructure.