Description

Detailed Parameter Table

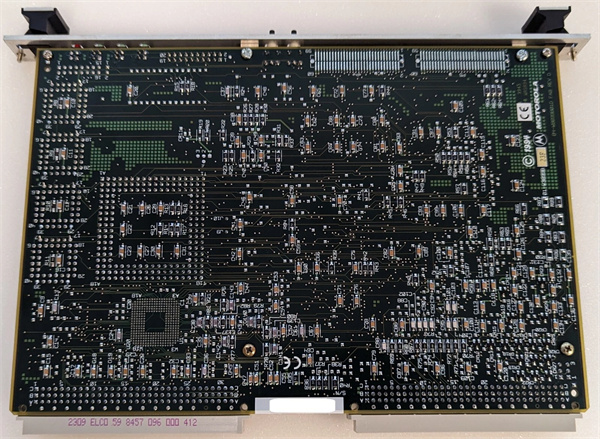

| Parameter name | Parameter value |

| Product model | MVME-167-04B |

| Manufacturer | Motorola (now integrated into Emerson’s industrial automation product portfolio) |

| Product category | Industrial VMEbus Single-Board Computer (SBC); mid-range real-time processing solution |

| Processor | Motorola PowerPC 603e RISC processor, operating at 166 MHz (32-bit data/address bus) |

| Memory | 64 MB SDRAM (expandable up to 128 MB via on-board DIMM slot); 4 MB Flash ROM (for boot code/OS storage) |

| Storage Interface | Integrated IDE controller (supports 2.5″ IDE hard drives/SSD); 1x CompactFlash slot (Type I/II) for removable storage |

| Communication Interfaces | 2x RS-232 serial ports (DB-9); 1x 10/100 Base-TX Ethernet port (RJ45, supports TCP/IP, UDP); 1x Serial RapidIO port (4x lane, 1.25 Gbps per lane) |

| Expansion Slots | 1x PMC (PCI Mezzanine Card) slot (32-bit/33 MHz) for adding I/O modules (e.g., analog I/O, additional Ethernet) |

| Bus Compatibility | Complies with VMEbus IEEE 1014-1987 (3U form factor); supports VMEbus A16/A24/A32 address cycles, D8/D16/D32 data cycles; DMA (Direct Memory Access) |

| Environmental Requirements | Operating temperature: -10°C to 65°C (14°F to 149°F); Storage temperature: -40°C to 85°C (-40°F to 185°F); Relative humidity: 5% to 95% (non-condensing); Vibration resistance: 5-500 Hz, 1.5 g (peak); Shock resistance: 50 g (peak, 10 ms duration) |

| Physical Size | 3U VMEbus form factor (100 mm x 160.02 mm / 3.94 in x 6.30 in); weight: 220 g (0.49 lbs) |

| Installation Method | VMEbus backplane mounting; compatible with 3U/6U VME chassis; requires VMEbus standard power supply (+5V, ±12V) |

| Power Consumption | Typical: 12 W (at 25°C, full load); Maximum: 15 W |

| Operating System Support | Compatible with VxWorks 5.5+, QNX Neutrino, Linux for PowerPC; supports Motorola RTOS for legacy industrial applications |

| Diagnostic Features | Built-in self-test (BIST) for processor, memory, and Ethernet; LED indicators (power, Ethernet activity, BIST status); watchdog timer (configurable 1-60 second timeout) |

Motorola MVME-167-32B

Product Introduction

The Motorola MVME-167-04B is a mid-range industrial VMEbus single-board computer (SBC) developed by Motorola—a leader in legacy industrial computing—and now part of Emerson’s trusted product ecosystem. As a key model in the MVME-167 series, it is engineered to deliver balanced performance and expandability for real-time industrial control, data acquisition, and edge computing applications, bridging the gap between entry-level SBCs (e.g., MVME-147-023) and high-end variants (e.g., MVME-167-32B).

At its core, the Motorola MVME-167-04B leverages the PowerPC 603e processor (166 MHz) and 64 MB expandable SDRAM, enabling efficient execution of real-time control algorithms and handling of mid-volume sensor data. Its integrated communication interfaces—including Ethernet, Serial RapidIO, and serial ports—ensure seamless connectivity to field devices and upper-level systems, while the PMC expansion slot allows customization with I/O modules (e.g., analog I/O for process control). In automation architectures, the Motorola MVME-167-04B acts as a central processing hub: it collects data from modules like the MVME-717 digital input module and MVME-761-001 analog I/O module, processes it to execute control logic, and transmits commands to actuators via the MVME-712-11 digital output module. Its rugged design and wide temperature range make it ideal for manufacturing, energy, and transportation sectors where reliability in harsh conditions is critical.

Core Advantages and Technical Highlights

Balanced Performance for Mid-Range Industrial Tasks: The Motorola MVME-167-04B combines a 166 MHz PowerPC 603e processor with 64 MB SDRAM (expandable to 128 MB) to handle mid-complexity tasks—such as real-time monitoring of 50-100 sensors, execution of PID control loops, and data logging—without the cost of high-end SBCs. For example, in a water treatment plant, it can process flow rate, pH, and turbidity data from 60 sensors, run 10 PID loops to adjust chemical dosing, and log data to a CompactFlash card—all while maintaining <10 ms latency. This balance makes it a cost-effective choice for applications that need more power than entry-level SBCs but don’t require the 32-bit/500 MHz+ performance of the MVME-167-32B.

Flexible Expansion via PMC Slot: Unlike basic SBCs without expansion options, the Motorola MVME-167-04B includes a PMC slot (32-bit/33 MHz) that supports industry-standard mezzanine cards. This allows users to customize the SBC for specific needs: adding a PMC analog I/O card (e.g., Motorola MVME-231) for process control, a PMC Ethernet card for redundant network connectivity, or a PMC serial card for additional RS-485 ports. In a factory automation system, for instance, the Motorola MVME-167-04B can use a PMC analog I/O card to monitor temperature in 16 industrial ovens, while its native Ethernet port transmits data to a SCADA system—eliminating the need for separate I/O modules and simplifying system design.

Dual-Reliability Features for Uninterrupted Operation: The Motorola MVME-167-04B integrates two critical reliability tools: a configurable watchdog timer and non-volatile Flash storage. The watchdog timer (1-60 second timeout) automatically resets the SBC if software hangs—common in industrial environments with electrical interference—preventing unplanned downtime. The 4 MB Flash ROM stores the boot code and operating system, ensuring the SBC can restart reliably even if the IDE hard drive fails. In a power generation plant, where downtime can cost thousands of dollars per minute, these features ensure the Motorola MVME-167-04B maintains control of auxiliary systems (e.g., boiler feedwater pumps) even during software or storage anomalies.

Multi-Protocol Communication for Seamless Integration: The Motorola MVME-167-04B supports three key communication protocols to connect with diverse industrial systems: 10/100 Ethernet (TCP/IP/UDP) for SCADA/HMI integration, Serial RapidIO (1.25 Gbps per lane) for high-speed data transfer to other VMEbus modules (e.g., MVME-910-3 Ethernet module), and RS-232 for legacy devices (e.g., HMIs, barcode scanners). In a mixed legacy/modern system, for example, it can use Ethernet to send real-time data to a cloud-based analytics platform, Serial RapidIO to synchronize with a MVME-162-001 SBC controlling a robotic arm, and RS-232 to interface with a 20-year-old temperature controller—eliminating the need for protocol converters and reducing integration costs.

Typical Application Scenarios

The Motorola MVME-167-04B excels in mid-scale industrial applications requiring balanced performance and expandability—including manufacturing process control, smart grid substation monitoring, and railway signaling systems. In a semiconductor packaging facility, it is deployed to control 20 automated die-bonding machines. The Motorola MVME-167-04B uses its native Serial RapidIO port to receive high-speed position data (1.25 Gbps) from each machine’s servo controllers, processes the data to adjust bonding pressure and speed, and sends commands via its RS-232 port to a legacy HMI for operator monitoring. Its PMC slot is populated with an analog I/O card to monitor temperature in 8 bonding chambers, ensuring compliance with semiconductor quality standards. The SBC’s 64 MB SDRAM easily handles the concurrent processing of 20 machine data streams, while the watchdog timer prevents downtime if a servo controller sends corrupted data.

In a smart grid substation, the Motorola MVME-167-04B monitors and controls 30 medium-voltage circuit breakers. Its Ethernet port connects to a central utility SCADA system, transmitting real-time breaker status (open/closed) and current/voltage readings every 500 ms. The SBC uses its RS-232 port to communicate with legacy relay protection devices, while its CompactFlash slot logs 6 months of historical data for compliance reporting. The Motorola MVME-167-04B’s -10°C to 65°C operating range withstands the substation’s outdoor enclosure temperatures, and its vibration resistance (1.5 g peak) handles mechanical stress from nearby transformers. For utility operators, this ensures reliable monitoring of critical grid infrastructure without the cost of high-end substation SBCs.

In a railway signaling system, the Motorola MVME-167-04B controls signals and switches for a 5-mile stretch of track. Its PMC slot is equipped with a digital I/O card to interface with 32 track circuits (detecting train presence), while its Ethernet port sends train location data to a central dispatch system. The SBC’s watchdog timer resets the system if a track circuit signal is lost, preventing signal failures that could cause delays. The Motorola MVME-167-04B’s shock resistance (50 g peak) withstands vibrations from passing trains, and its low power consumption (12 W typical) makes it suitable for battery-backed emergency systems—critical for ensuring railway safety during power outages.

Motorola MVME-167-32B

Related Model Recommendations

Motorola MVME-167-32B: A high-performance variant of the Motorola MVME-167-04B, with a 32-bit/500 MHz PowerPC processor and 256 MB SDRAM. It is an upgrade for data-intensive applications (e.g., large-scale sensor networks) where the MVME-167-04B’s 166 MHz processor is insufficient.

Motorola MVME-147-023: An entry-level VMEbus SBC that complements the Motorola MVME-167-04B in distributed systems. The MVME-147-023 handles basic I/O control (e.g., conveyor belts), while the MVME-167-04B manages central data processing and SCADA communication.

Motorola MVME-231: A PMC analog I/O module designed for the Motorola MVME-167-04B. It adds 16 analog input/8 analog output channels, expanding the SBC’s ability to monitor and control process variables (e.g., temperature, pressure).

Motorola MVME-717: A digital input module that pairs with the Motorola MVME-167-04B. The MVME-717 collects data from 32 limit switches/sensors, which the MVME-167-04B processes to execute control logic (e.g., stopping a machine if a switch is triggered).

Motorola MVME-050: An industrial power supply module that powers the Motorola MVME-167-04B. Its stable +5V/±12V outputs ensure the SBC’s processor and memory operate without voltage fluctuations, critical for real-time processing.

Motorola MVME-910-3: An Ethernet communication module that works with the Motorola MVME-167-04B. It adds a second 10/100 Ethernet port for redundant network connectivity, ensuring the SBC remains connected to SCADA systems if the primary Ethernet port fails.

Motorola MVME-712-11: A digital output module compatible with the Motorola MVME-167-04B. The MVME-167-04B sends commands to the MVME-712-11, which activates high-current actuators (e.g., solenoid valves, motor starters) in manufacturing lines.

Motorola MVME-162-001: A legacy high-performance SBC that integrates with the Motorola MVME-167-04B via Serial RapidIO. The MVME-162-001 handles motion control for robotics, while the MVME-167-04B manages data logging and HMI communication.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-167-04B, verify the VMEbus chassis supports 3U modules and provides stable +5V/±12V power (use a multimeter to check voltage tolerance within ±5%). Gather tools: anti-static wristband (to protect the processor and memory chips), Phillips screwdriver (for chassis mounting), Ethernet cable tester (to validate network connectivity), and a laptop (for OS configuration). If using a PMC card, insert it into the SBC’s PMC slot before installation—align the card with the slot guides, press gently until seated, and secure with the locking screw. Ensure the chassis is powered off, clean the VME backplane connector with a dry brush to remove dust, then slide the Motorola MVME-167-04B into the backplane until fully seated. Secure with screws (torque to 0.4 N·m) to avoid loose connections.

Maintenance suggestions: For daily upkeep of the Motorola MVME-167-04B, inspect the LED indicators weekly—steady green power LED, blinking Ethernet activity LED, and solid green BIST LED indicate normal operation. A red BIST LED signals a hardware fault (e.g., memory failure); run the BIST utility via the OS to identify the issue. Clean the SBC’s air vents monthly with compressed air (low pressure, 30 PSI max) to prevent overheating—dust buildup can raise processor temperature by 10-15°C, reducing performance. Every 3 months, back up the Flash ROM and CompactFlash data to a secure server—critical for recovering the system if storage fails. If the SBC hangs, check the watchdog timer log (via the OS) to determine if a software crash occurred; update the OS or application firmware if crashes are frequent. Store spare Motorola MVME-167-04B units in anti-static bags in a climate-controlled environment (15°C to 25°C, 40% to 60% humidity) to preserve processor and memory life.

Service and Guarantee Commitment

The Motorola MVME-167-04B is backed by a 24-month factory warranty (extendable to 48 months via premium service contracts), covering defects in materials and workmanship—including processor failures, memory errors, and Ethernet port malfunctions. If a defect is identified during the warranty period, we provide free replacement or repair (with a 48-hour turnaround for in-stock units) to minimize operational downtime, as SBC failures can disable entire control systems.

Our technical support team offers 24/7 assistance via email and online portals, staffed by engineers specialized in MVME series SBCs. They can help with Motorola MVME-167-04B configuration (e.g., PMC card setup, watchdog timer adjustment), OS installation (e.g., VxWorks 5.5), and troubleshooting (e.g., Ethernet connectivity issues, BIST failures). For legacy users, we maintain a stock of critical components (e.g., PowerPC 603e processors, SDRAM modules) to support long-term maintenance, even for discontinued models. We also offer on-site commissioning services—our technicians visit your facility to test the Motorola MVME-167-04B’s performance, verify PMC card integration, and train your team on maintenance best practices. Our commitment to the Motorola MVME-167-04B extends beyond the sale—we strive to keep your industrial control systems reliable, so you can focus on optimizing operational efficiency.