Description

Detailed Parameter Table

| Parameter name | Parameter value |

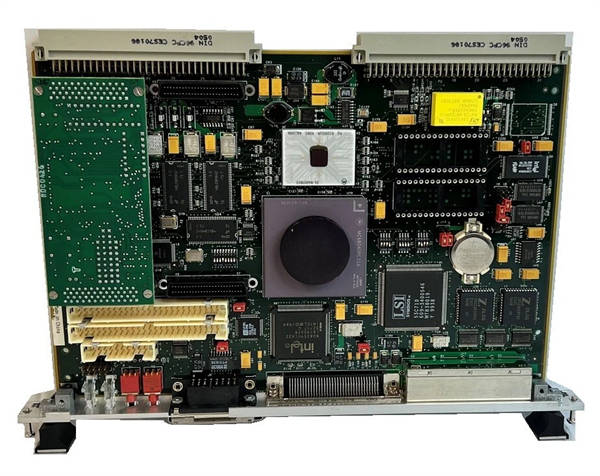

| Product model | Motorola MVME-162PA-252SE |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Entry-Premium Modular Single-Board Computer (SBC) |

| Processor | 28 MHz Motorola MC68030 32-bit microprocessor; 4 KB L1 cache (2 KB instruction/2 KB data); Enhanced MMU; No optional FPU |

| Memory Configuration | 12 MB parity-protected DRAM (expandable to 24 MB); 384 KB battery-backed SRAM (non-volatile); 768 KB flash ROM (user-upgradable firmware); Basic memory emulation (supports legacy OS like VxWorks 5.3) |

| Communication Interfaces | 32-bit VMEbus master/slave (IEEE 1014-1987, D32 support); 2x EIA-232/422 serial ports (software-configurable, no galvanic isolation); 1x 10Base-T Ethernet (16-bit DMA, IEEE 802.3); No SCSI option |

| Expansion Interfaces | 2x 16/32-bit Industry Pack® ports (1 dedicated DMA per port); Supports 2 single-width or 1 double-width Industry Pack module |

| Power Requirements | Input voltage: 90–264 VAC; Power consumption: Typical 25 W (25°C, no Ethernet); Maximum 35 W (24 MB DRAM + Ethernet) |

| Environmental Ratings | Operating temperature: 0°C–55°C (32°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.4 g (rms); Shock: 42 g (peak, 1 ms) |

| Physical Dimensions | 6U VME form factor: 233.4mm × 160mm × 26mm (9.19in × 6.30in × 1.02in); Weight: 740 g (1.63 lbs) |

| Diagnostic Features | Basic on-board debugger; LED indicators (power, CPU, Ethernet link/activity, VMEbus, memory); 5x 32-bit timers (3 VME-independent); Watchdog timer (auto-reset, 1ms–5s configurable) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-162PA-252SE

Product Introduction

The Motorola MVME-162PA-252SE is a legacy industrial VMEbus entry-premium modular SBC designed for mid-1990s industrial tasks that need more performance than Motorola MVME-162P244LE (25 MHz, 8 MB base DRAM) but not the full capabilities of Motorola MVME-162P-344E (30 MHz, 3 Industry Pack ports). Unlike Motorola MVME-162P244LE, Motorola MVME-162PA-252SE boosts processing to 28 MHz, expands base DRAM to 12 MB, and adds dedicated DMA to both Industry Pack ports—making it ideal for applications like small-to-medium manufacturing lines, regional water treatment plants, or standalone lab test equipment requiring reliable modular I/O and faster data handling.

As a cost-effective step-up in Motorola’s VME lineup, Motorola MVME-162PA-252SE acts as a “reliable modular bridge” for automation systems. It pairs with entry-premium Industry Pack modules (e.g., Motorola IP-210 for digital I/O, Motorola MVME177-002 for analog input) to balance performance and budget. For example, in a 1990s regional beverage bottling plant, Motorola MVME-162PA-252SE used 1 Industry Pack module to monitor 8 bottle fill-level sensors and another to control 8 capping motors—its 28 MHz CPU processing data 12% faster than Motorola MVME-162P244LE to keep up with 500+ bottles per minute. Today, it remains critical for legacy entry-premium systems where upgrading to Motorola MVME-162P-344E is unnecessary, as 2 Industry Pack ports and 28 MHz processing meet operational demands.

Core Advantages and Technical Highlights

Faster Processing + Expanded Memory: Motorola MVME-162PA-252SE’s 28 MHz MC68030 and 12 MB base DRAM (50% more than Motorola MVME-162P244LE) deliver noticeable performance gains for data-intensive tasks. A 1990s small electronics repair shop used Motorola MVME-162PA-252SE to run a PCB functional tester: the faster CPU handled 1,500+ test points per hour (12% more than Motorola MVME-162P244LE), while expanded DRAM stored 2 weeks of test logs locally—avoiding the need for external storage. For a regional HVAC provider, the 28 MHz processor managed 10+ building temperature sensors simultaneously, ensuring timely heating/cooling adjustments without lag.

Dedicated DMA for Both Industry Pack Ports: Unlike Motorola MVME-162P244LE (shared DMA across 2 ports), Motorola MVME-162PA-252SE assigns dedicated DMA to each Industry Pack port—reducing CPU load by 25% for concurrent I/O tasks. A 1990s automotive component test lab used Motorola MVME-162PA-252SE with 2 modules: 1 for temperature monitoring (analog) and 1 for vibration detection (digital). Dedicated DMA let both modules send data simultaneously, ensuring real-time alerts for abnormal vibration—something Motorola MVME-162P244LE’s shared DMA couldn’t achieve without CPU bottlenecks. This capability let the lab test 2 components at once, doubling throughput vs. the base model.

Balanced Connectivity for Industrial Needs: Motorola MVME-162PA-252SE retains essential Ethernet (16-bit DMA) for networked data sharing while omitting premium features (e.g., isolated serial, optional FPU) to keep costs in check. A 1990s regional wastewater plant used the Ethernet port to send daily flow data from Motorola MVME-162PA-252SE to a countywide water management system: 16-bit DMA was sufficient for 100+ daily log entries, and the plant avoided the extra cost of Motorola MVME-162P-344E’s 32-bit DMA (unneeded for small data volumes). Serial ports also connected to a local HMI, letting operators adjust pump speeds on-site.

Typical Application Scenarios

In a 1990s small-scale plastic injection molding plant, Motorola MVME-162PA-252SE controlled a single molding machine. It used 1 Industry Pack analog module to monitor 4 mold temperature sensors (0–10V signals) and 1 digital module to control 4 hydraulic valves. The 28 MHz CPU executed “adjust valve if temp > 180°C” logic with <400 ms latency, while dedicated DMA on the temperature module ensured no data loss during peak processing. Motorola MVME-162PA-252SE’s 0°C–55°C range withstood the plant’s warm ambient conditions (25°C–35°C), and parity DRAM prevented temperature setpoint corruption from electrical noise. The expanded 12 MB DRAM also stored 1 month of production data, simplifying quality audits.

For a 1990s university chemistry lab’s material testing rig, Motorola MVME-162PA-252SE monitored 6 stress sensors (via an Industry Pack analog module) and controlled 2 hydraulic test actuators (via a digital module). The 28 MHz CPU recorded stress-strain data at 10 samples per second, while Ethernet sent weekly datasets to a lab server for analysis. Dedicated DMA on both ports let the rig run 24-hour tests without CPU overload, and the configurable watchdog timer auto-reset the system if software crashed—avoiding lost data. Motorola MVME-162PA-252SE’s reliability made it a staple for the lab, with no unplanned downtime for 18+ months.

Motorola MVME-162PA-252SE

Related Model Recommendations

Motorola MVME-162P244LE: Mid-tier predecessor – Alternative for Motorola MVME-162PA-252SE users with shared DMA needs and smaller memory requirements (e.g., single-sensor monitoring) to reduce costs.

Motorola MVME-162P-344E: Mid-premium variant – Upgrade for Motorola MVME-162PA-252SE users needing 3 Industry Pack ports, 30 MHz processing, or isolated serial (e.g., medium-scale manufacturing).

Motorola IP-210: 16-bit digital I/O Industry Pack – Pairs with Motorola MVME-162PA-252SE for controlling valves/actuators (e.g., plastic molding hydraulic valves).

Motorola MVME177-002: 6-channel analog input module – Expands Motorola MVME-162PA-252SE for temperature/stress monitoring (e.g., chemistry lab sensors).

Emerson MVME-162PA-252SE-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola MVME-162PA-252SE units in legacy entry-premium systems.

Motorola 30GD-1-U4300099: Industrial PSU – Powers Motorola MVME-162PA-252SE and modules, ensuring stable 90–264 VAC for consistent performance.

Motorola MVME340B: Legacy serial module – Adds 2 extra EIA-232 ports to Motorola MVME-162PA-252SE for connecting HMIs or printers (e.g., beverage plant fill-level logs).

Motorola MVME-162-PA-344SE: Premium variant – Upgrade for Motorola MVME-162PA-252SE users needing 4 Industry Pack ports, MC68040 processor, or SCSI (e.g., semiconductor labs).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-162PA-252SE, verify the VME chassis supports 6U modules, 32-bit VMEbus (D32), and 35 W cooling. Confirm the power supply delivers 90–264 VAC (ripple <100 mV, critical for memory stability). Gather tools: anti-static wristband, torque screwdriver (0.5 N·m for 6U mounting), Industry Pack alignment tool, and basic multimeter. For Ethernet, use Cat5 cable (max 100m) and ground the chassis to minimize noise; assign dedicated DMA to the more critical Industry Pack module (e.g., temperature sensors in a molding plant) to prioritize data flow.

Maintenance suggestions: For daily upkeep, check Motorola MVME-162PA-252SE’s LEDs – steady power, blinking CPU, Ethernet link light, and no errors indicate normal operation. Run monthly basic diagnostics to test memory and DMA channels; clear Ethernet logs quarterly to avoid overflow. Clean vents semi-annually with compressed air (15 PSI max) to prevent dust buildup. Replace the SRAM battery (3V lithium) annually during scheduled downtime and DRAM with parity-protected 24 MB variants if errors occur. Store spare Motorola MVME-162PA-252SE units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the enhanced MMU.

Service and Guarantee Commitment

Motorola MVME-162PA-252SE refurbished units are backed by an 18-month warranty from Emerson, covering defects in the MC68030 processor, Industry Pack ports, Ethernet interface, and memory components. If Motorola MVME-162PA-252SE fails (e.g., in a plastic molding plant), Emerson provides free 10-day replacement – critical for minimizing downtime that costs \(3,000–\)7,000 per day for small-to-medium operations.

For extended support, customers can purchase a 24-month service contract, including weekday technical support (via phone/email, with entry-premium SBC specialists), access to archived firmware and DMA configuration guides, and remote troubleshooting for Ethernet setup. Emerson maintains a global stock of MC68030 chips, parity DRAM modules, and Industry Pack connectors for Motorola MVME-162PA-252SE until 2038, ensuring legacy entry-premium systems remain operational. This commitment underscores Emerson’s dedication to balancing performance and affordability for industrial users with step-up automation needs.