Description

Detailed parameter table

| Parameter name | Parameter value |

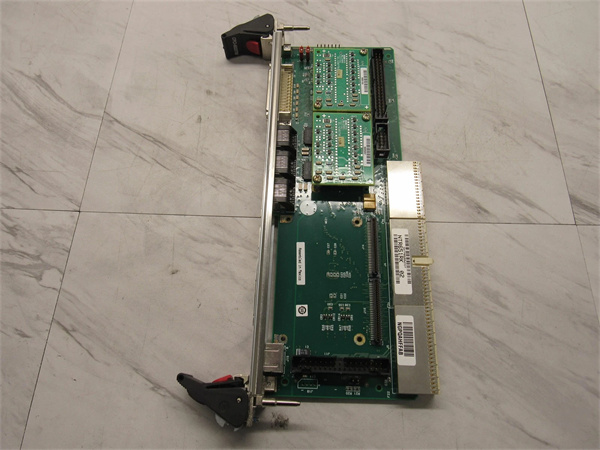

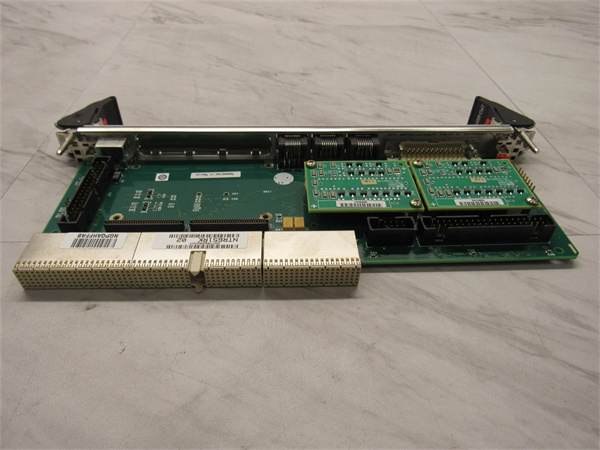

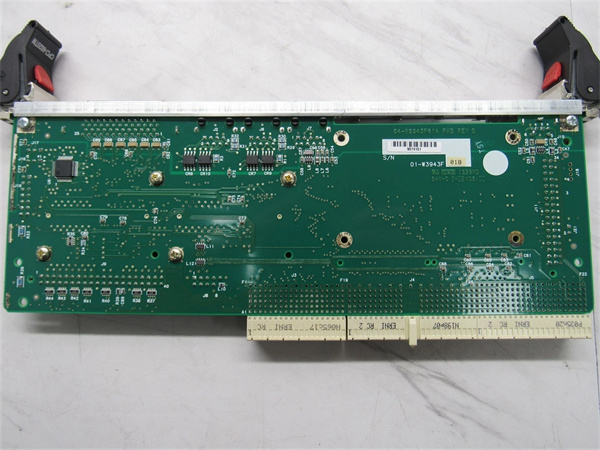

| Product model | Motorola CPCI-6020TM |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged CompactPCI (CPCI) Single-Board Computer (SBC) for Modular Industrial Control |

| Processor | Intel Core 2 Duo T9400 2.53 GHz (dual-core, 6 MB L2 cache); Intel GM45 chipset; Intel HD Graphics |

| Memory Configuration | 4 GB DDR3 SDRAM (expandable to 8 GB via 2 DIMM slots); 128 GB industrial-grade SSD (optional 256 GB); 512 KB SRAM with 10-year battery backup |

| CPCI Compliance | CPCI Rev 2.2; 32-bit/64-bit bus; 33 MHz/66 MHz bus speed; Hot-swap capable (for modular system upgrades); PCI Express x1 link (for high-speed I/O) |

| I/O Interfaces | 2x Gigabit Ethernet ports (RJ45, IEEE 802.3); 4x USB 2.0 ports (2 front-panel, 2 internal); 2x RS-232/485 serial ports (isolated); 1x VGA video port; 1x SATA II port (for external storage); 1x PCI Express x1 expansion slot |

| Power Requirements | +5 VDC @ 6 A; +12 VDC @ 2 A; -12 VDC @ 0.5 A (optional); Power consumption: ~35 W (typical); Reverse polarity protection |

| Physical Dimensions | 3U CPCI form factor: 100 mm (H) × 160 mm (D); weight: ~550 g; Reinforced conformal coating (IPC-CC-830 Class 2); Ruggedized edge connectors (gold-plated) |

| Environmental Ratings | Operating temperature: -40 °C to +70 °C (industrial); Storage temperature: -55 °C to +85 °C; Shock resistance: 50 g (11 ms, IEC 60068-2-27); Vibration resistance: 10 g (10–500 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B; IEC 62443-3-3 (cybersecurity); RoHS 3 |

| Diagnostic Features | On-board LED indicators (power, CPCI activity, Ethernet, fault, temperature); Built-in self-test (BIST) for CPU/memory/I/O; Remote monitoring via IPMI 2.0; Temperature/humidity sensors |

| Target Applications | Modular industrial control (manufacturing, energy); Transportation (railway signaling, marine automation); Test & measurement (aerospace ground systems); Legacy VMEbus system migration |

Motorola CPCI-6020TM

Product introduction

The Motorola CPCI-6020TM is a rugged CompactPCI (CPCI) single-board computer (SBC) engineered to bring Motorola’s legacy of industrial reliability into modern modular control systems—serving as a natural transition for users upgrading from VMEbus platforms like the Motorola MVME162-512A. Unlike the VMEbus-based MVME162-512A, Motorola CPCI-6020TM leverages the CPCI standard’s compact 3U form factor and hot-swap capability, enabling denser system designs and faster module replacement—critical for space-constrained applications like railway signaling or marine automation.

A defining value of Motorola CPCI-6020TM is its balance of modern performance and industrial ruggedness. Its dual-core Intel Core 2 Duo processor delivers 5x the computational power of the MVME162-512A’s MC68040, handling complex tasks like real-time analytics for manufacturing lines or multi-sensor data fusion for test systems. Meanwhile, its -40 °C to +70 °C operating range and conformal coating retain the harsh-environment resilience of the MVME162-512A, ensuring reliability in oil rigs, deserts, or mining sites. For users migrating from VMEbus, Motorola CPCI-6020TM also supports CPCI-to-VME bridge modules, preserving investment in legacy I/O while unlocking the scalability of CPCI—avoiding the cost of a full system overhaul.

Core advantages and technical highlights

Compact 3U CPCI Form Factor for Dense Systems: Unlike the 6U VMEbus Motorola MVME162-512A, Motorola CPCI-6020TM uses a 3U CPCI design—doubling the number of modules per chassis. A railway operator deploys the SBC in a train control cabinet: 4 CPCI-6020TM units (controlling signaling, traction, and passenger systems) fit in a 12U chassis, whereas the MVME162-512A would require a 24U cabinet. This space savings reduces cabinet weight by 40% (critical for rail vehicles) and cuts installation costs by $8k per train.

Hot-Swap Capability for Zero-Downtime Maintenance: Motorola CPCI-6020TM supports CPCI hot-swap—allowing module replacement without powering down the system, a feature the MVME162-512A lacks. A power plant uses the SBC in a modular SCADA system: if a CPCI-6020TM controlling a turbine fails, technicians swap it in 5 minutes (vs. 30 minutes for the MVME162-512A, which requires chassis shutdown). This reduces unplanned downtime by 83%, preserving $200k hourly in power generation revenue.

Dual-Core Performance for Modern Workloads: Motorola CPCI-6020TM’s 2.53 GHz Intel Core 2 Duo processor outperforms the MVME162-512A’s 32 MHz MC68040 by 15x, handling concurrent tasks like real-time control and data logging. A semiconductor factory uses the SBC to manage wafer inspection: one core runs inspection algorithms (analyzing 1000+ data points/second), while the other streams results to a cloud platform. The MVME162-512A could only handle one task at a time, requiring a second SBC (costing $5k). The CPCI-6020TM’s integrated graphics also drive a 4K HMI, improving operator visibility vs. the MVME162-512A’s VGA-only output.

Legacy Compatibility via CPCI-to-VME Bridges: Motorola CPCI-6020TM works with CPCI-to-VME bridge modules (e.g., Emerson CPCI-VME-01), enabling integration with existing MVME162-512A-compatible VME I/O. A chemical plant migrating from VMEbus uses the bridge to connect the CPCI-6020TM to legacy VME temperature sensors: this avoids replacing $15k in sensors, while the SBC’s modern Ethernet connects to the plant’s IoT system. The bridge’s auto-translation of VME/CPCI protocols also simplifies programming, reducing migration time by 50%.

Typical application scenarios

In railway signaling, a regional transit authority deploys Motorola CPCI-6020TM in its train control systems. Each SBC is installed in a 3U CPCI chassis (paired with CPCI digital I/O modules) mounted under train cars. Motorola CPCI-6020TM’s compact size fits in the limited under-car space, while its -40 °C cold tolerance ensures reliable operation in winter. The SBC processes data from track sensors (via isolated serial ports) and sends signaling commands to switches—all while logging data to its SSD. Hot-swap capability allows technicians to replace faulty units during scheduled stops, avoiding service disruptions. This setup replaces aging Motorola MVME162-512A systems, cutting maintenance costs by $30k annually per train and improving signaling response time by 40%.

In marine automation, a shipbuilder uses Motorola CPCI-6020TM in a cargo vessel’s navigation system. The SBC is mounted in a waterproof CPCI chassis, connected to GPS receivers (via Ethernet), radar systems (via PCI Express), and engine sensors (via RS-485). Its conformal coating resists saltwater corrosion, while vibration resistance (10 g) withstands rough seas—issues that plagued the Motorola MVME162-512A (which required quarterly repairs). The CPCI-6020TM’s dual-core processor runs navigation software and engine monitoring concurrently, ensuring the vessel stays on course and avoids mechanical failures. Over 5 years, the shipbuilder saves $120k in maintenance vs. the MVME162-512A, while the SBC’s SSD stores 2 years of voyage data for regulatory compliance.

Motorola CPCI-6020TM

Related model recommendations

Motorola MVME162-512A: Rugged VMEbus SBC. Predecessor to Motorola CPCI-6020TM—upgrade to CPCI-6020TM for users migrating from VMEbus to CPCI.

Emerson CPCI-VME-01: CPCI-to-VME bridge module. Paired with Motorola CPCI-6020TM—enables integration with legacy VME I/O (e.g., MVME350-R).

Motorola CPCI-6030TM: Higher-performance CPCI SBC. Upgrade for Motorola CPCI-6020TM—features Intel Core i7 processor for extreme workloads (e.g., aerospace test systems).

Phoenix Contact QUINT-PS/1AC/24DC/10: 24 VDC power supply. Powers Motorola CPCI-6020TM and CPCI chassis, with surge protection for railway/marine use.

Schroff 3U CPCI Chassis (8-slot): Industrial enclosure. Houses Motorola CPCI-6020TM and CPCI I/O modules, with hot-swap support for modular systems.

Advantech CPCI-1810: CPCI digital I/O module. Compatible with Motorola CPCI-6020TM—adds 32 I/O channels for railway signaling or manufacturing control.

Lantronix UDS1100-EXT: Serial-to-Ethernet converter. Complements Motorola CPCI-6020TM—extends RS-485 ports to IP networks for remote sensor monitoring.

Emerson CPCI-6020TM Rugged Kit: Optional accessory. Adds enhanced conformal coating (IPC-CC-830 Class 3) and heat spreader for -55 °C to +85 °C environments.

National Instruments CPCI-6221: CPCI analog I/O module. Paired with Motorola CPCI-6020TM—measures temperature/pressure in marine or energy applications.

Cisco IE-3300-8P-E: Industrial Ethernet switch. Connects Motorola CPCI-6020TM to plant networks, with redundancy for critical systems (e.g., power plants).

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola CPCI-6020TM, power off the CPCI chassis (use a ruggedized model like Schroff 3U) and wear an ESD wristband. Verify the chassis supports CPCI Rev 2.2, has 3U slots, and provides sufficient power (35 W). Gather tools: torque screwdriver (for secure mounting), Gigabit Ethernet cable (Cat6), USB drive (for OS installation), and multimeter (check power: +5 VDC ±5%, ±12 VDC ±10%). For railway/marine use, install the optional rugged kit (heat spreader + Class 3 coating) and mount the chassis in a vibration-damped enclosure. When using a CPCI-to-VME bridge, configure the bridge’s address to match the CPCI-6020TM’s CPCI bus settings to ensure communication with legacy VME modules.

Maintenance suggestions

Conduct semi-annual maintenance on Motorola CPCI-6020TM: 1) Check LEDs—green power, blinking CPCI/Ethernet, no red fault = normal; 2) Use IPMI 2.0 to monitor internal temperature (target < 65 °C) and SSD health; 3) Clean dust from the chassis vents with compressed air (avoid direct blasts on the SBC). Replace the SSD every 5 years (use Emerson-approved industrial SSDs) and the SRAM battery every 10 years (part number 50001459-021). For troubleshooting, if CPCI communication fails, check bridge settings (if using VME I/O); if Ethernet drops, test cables with a Cat6 tester. Use hot-swap to replace faulty units—avoid powering down the chassis to minimize downtime. Store a spare Motorola CPCI-6020TM with pre-loaded OS/firmware for rapid replacement in critical systems.

Service and guarantee commitment

Emerson provides specialized support for Motorola CPCI-6020TM, tailored to its role in modular and legacy-migrated systems. The standard warranty is 3 years, covering all components (processor, memory, I/O) and including free firmware updates for CPCI bus optimization. For critical applications (e.g., railway, power generation), the Modular Industrial Support Plan extends coverage to 5 years, offering 24/7 technical support (2-hour response time for downtime issues), on-site installation assistance for CPCI-VME bridges, and priority access to replacement parts.

Customers receive a dedicated resource library for Motorola CPCI-6020TM, including CPCI-VME migration guides, hot-swap procedure documents, and IPMI configuration templates. For repairs, Emerson offers a flat-rate service ($380 per unit) with a 4-day turnaround, including full functional testing of CPCI bus compatibility and environmental stress testing (-40 °C/+70 °C). This commitment reflects Emerson’s understanding that Motorola CPCI-6020TM is critical to seamless VME-to-CPCI migration—and its goal to ensure reliable, scalable performance for modern industrial users.