Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

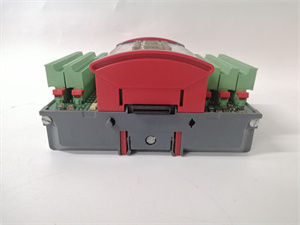

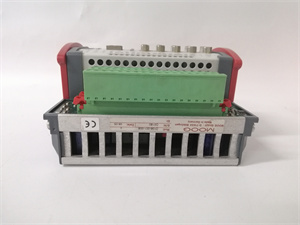

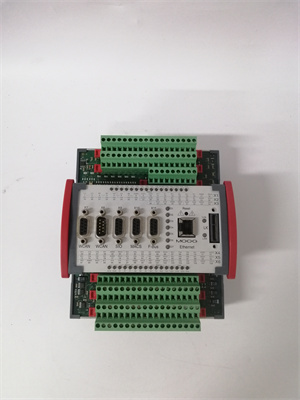

| Product Model | MOOG D136-001-008 |

| Manufacturer | MOOG |

| Product Category | Servo Valve Controller |

| Operating Voltage | 220 V |

| Output Frequency | 30 kHz |

| Processor | High-Performance DSP |

| Memory | N/A |

| Input Interfaces | Analog, Digital |

| Output Interfaces | Analog, Digital |

| Communication Protocols | RS-485, CANopen |

| Operating Temperature Range | -20°C to +85°C |

| Dimensions | 140mm x 140mm x 80mm |

| Weight | 1.5 lbs |

| Protection Class | IP54 |

D136-001-008

Product Introduction

The MOOG D136-001-008 is a high-performance servo valve controller designed for precise motion control in demanding industrial applications. This controller is part of MOOG’s advanced automation solutions, offering exceptional precision and reliability for hydraulic and pneumatic servo valve control. It features a high-performance digital signal processor (DSP) and advanced control algorithms, enabling fast response and accurate control of position, speed, and force. The MOOG D136-001-008 is built to operate in harsh industrial environments, with a wide operating temperature range and robust design. Its compact size and versatile communication options make it an ideal choice for integrating into modern industrial automation systems.

Core Advantages and Technical Highlights

High Precision and Performance

The MOOG D136-001-008 delivers high-precision control with a response time of ≤ 1 ms, ensuring instantaneous adjustments for precise control of motors, pumps, or other mechanical systems. It supports high-speed sampling and precise calculations, enabling accurate position, speed, and force control.

Robust and Reliable Design

This controller is designed for long-term stability and reliability, with a wide operating temperature range of -20°C to +85°C. It features a compact and sturdy design, with an IP54 protection rating to withstand dust and moisture. The MOOG D136-001-008 also includes multiple protection functions, such as overcurrent, overvoltage, and undervoltage protection, to safeguard the controller and servo valve.

Versatile Communication Capabilities

The MOOG D136-001-008 supports multiple communication protocols, including RS-485 and CANopen, facilitating seamless integration with existing industrial systems. This ensures efficient data exchange and enhances system interoperability.

User-Friendly and Flexible

The MOOG D136-001-008 provides a user-friendly interface and supports various programming methods, such as C/C++, MATLAB, and LabVIEW. This allows users to customize control and integration according to their specific needs. Its compact size and lightweight design make it easy to install and maintain.

Compliance and Safety

The MOOG D136-001-008 is certified to ISO 9001 standards, ensuring compliance with global quality and safety benchmarks. This makes it a reliable choice for industries where safety and regulatory compliance are paramount.

D136-001-008

Typical Application Scenarios

The MOOG D136-001-008 is widely used in various industrial sectors, including manufacturing, aerospace, defense, and automotive. In manufacturing plants, it controls robotic arms and CNC machinery, ensuring high precision and efficiency. In aerospace and defense, it is used in flight control systems and simulators, providing reliable and accurate control. For automotive applications, the MOOG D136-001-008 is used in suspension systems, braking systems, and steering systems to improve driving control and safety. Its ability to operate in extreme conditions and provide real-time monitoring makes it a versatile solution for modern industrial automation.

Related Model Recommendations

-

MOOG D136-001-007: Similar model with a rated power of 0.7kW.

-

MOOG D136-001-009: Similar model with a rated power of 1.1kW.

-

MOOG D136-003-001: Voltage monitoring module, complementary to the MOOG D136-001-008.

-

MOOG T161-902A-00-B4-2-2A: Serial control module, compatible with the MOOG D136-001-008.

-

MOOG D136-001-001: An alternative servo valve controller with similar features.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation

Before installing the MOOG D136-001-008, ensure the environment meets the specified temperature and humidity requirements. Use the appropriate tools and safety equipment to secure the module in place. Ensure all connections are properly grounded to prevent electrical interference. Follow the manufacturer’s guidelines for wiring and mounting to ensure optimal performance and safety.

Maintenance Suggestions

Regularly inspect the MOOG D136-001-008 for signs of wear or damage, and replace any compromised components promptly. Keep the module clean and free from dust to prevent overheating and ensure efficient operation. Perform routine software updates and firmware upgrades to maintain optimal performance and security. Store spare parts in a dry and cool place to ensure their availability when needed.

Service and Guarantee Commitment

The MOOG D136-001-008 is backed by a comprehensive warranty and after-sales service commitment. MOOG guarantees the quality of the product and provides a 12-month warranty period from the date of purchase. The company offers technical support and troubleshooting assistance to ensure that customers receive the best possible experience with their products. MOOG is dedicated to providing timely and efficient service, ensuring that any issues are resolved quickly and effectively