Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product Model | METSO D201376 |

| Manufacturer | METSO |

| Product Category | Industrial Control Module |

| Operating Voltage | 10 VDC to 30 VDC |

| Max Input Current | 300 mA |

| Communication Interface | Ethernet, RS-485 |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Protection Class | IP67 |

| Dimensions | 120mm x 80mm x 35mm |

| Weight | 0.75 kg |

| Certifications | CE, UL, RoHS |

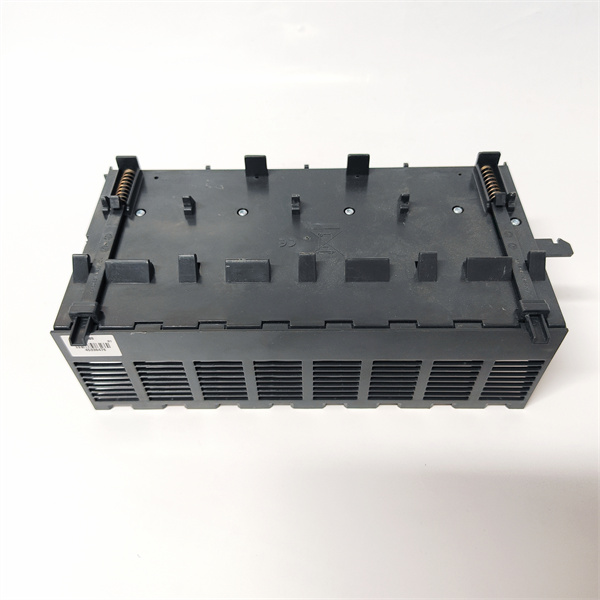

METSO D201376

Product Introduction

The METSO D201376 is a high-performance industrial control module designed for complex automation systems. It offers robust performance and reliable operation in demanding industrial environments. This module is engineered to provide precise control and monitoring capabilities, making it an essential component for modern manufacturing facilities.

Core Advantages and Technical Highlights

High Precision and Reliability

The METSO D201376 features high-precision signal processing and a wide operating temperature range of -20°C to +70°C. It supports multiple communication protocols, including Modbus RTU and Ethernet, ensuring seamless integration with existing industrial networks.

Versatile Communication Capabilities

This module supports multiple communication interfaces, such as Ethernet and RS-485, facilitating integration with PLCs, SCADA systems, and other industrial devices. It also supports OPC UA for enhanced data visualization capabilities.

Robust and Durable Design

The METSO D201376 is designed with a compact and modular architecture, making it easy to integrate into existing systems. It features an IP67 protection rating, ensuring resistance to dust, moisture, and vibration.

User-Friendly and Flexible

The module includes a multilingual and graphical interface, supporting up to 15 languages and 20 graphical symbols. It also features integrated virtual ladder logic, supporting complex control logic development.

METSO D201376

Typical Application Scenarios

The METSO D201376 is widely used in various industrial sectors, including:

-

Manufacturing: For production line control, data acquisition, and equipment monitoring.

-

Energy & Utilities: Monitoring temperature, pressure, and other parameters in power plants and chemical plants.

-

Process Industries: Optimizing process flows in chemical, pharmaceutical, and food processing industries.

-

Conveying Systems: Reducing energy consumption and maintenance costs through zero pressure accumulation control technology.

Related Model Recommendations

-

METSO D201380: A complementary analog input module with high precision and multiple channels.

-

METSO D201381: An advanced control module with enhanced features for complex applications.

-

METSO D201382: A higher-end model with additional I/O capabilities and extended temperature range.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation

Ensure the environment meets the specified temperature and humidity requirements. Use appropriate tools and safety equipment to secure the module in place. Connect the input signal lines and communication cables according to the manufacturer’s guidelines.

Maintenance Suggestions

Regularly inspect the module for signs of wear or damage. Use dedicated debugging software to check and update module parameters as needed. Keep the module clean and free from dust to prevent overheating and ensure efficient operation.

Service and Guarantee Commitment

The METSO D201376 is backed by a comprehensive warranty and after-sales service commitment. METSO guarantees the quality of the product and provides a 12-month warranty period from the date of purchase. The company offers technical support and troubleshooting assistance to ensure that customers receive the best possible experience with their products.