Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

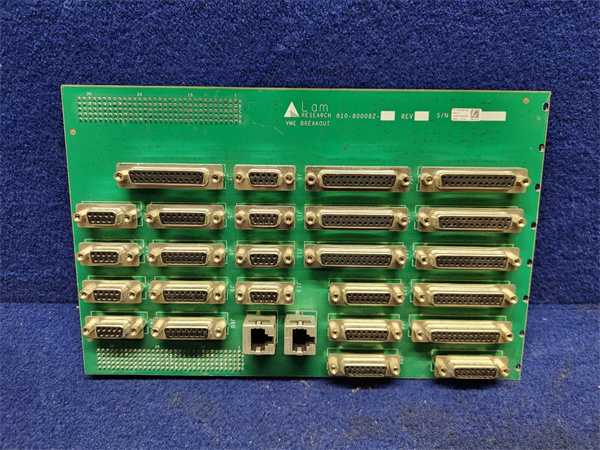

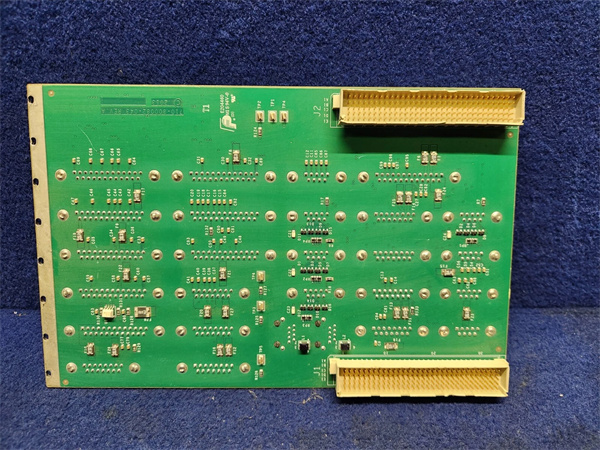

| Product model | 810-800082-043 |

| Manufacturer | LAM Research |

| Product category | High-Voltage Power Supply Module (for Semiconductor Plasma Processing Systems) |

| Input Voltage Range | 200–240V AC (single-phase), 50/60 Hz |

| Output Voltage Range | 0–5000V DC (adjustable, 0.1V resolution) |

| Output Current Capacity | 0–100mA DC (continuous); 120mA DC (peak, 5s max) |

| Voltage Regulation Accuracy | ±0.05% of set output voltage (at full load) |

| Interface Type | Ethernet (10/100Base-T) + RS-485; 4x 24-pin terminal blocks (power/signals) |

| Communication Protocol | Modbus TCP/IP, Ethernet/IP, and Modbus RTU (configurable via software) |

| Operating Temperature Range | 10°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 5% to 85% RH (non-condensing, no dew formation) |

| Physical Dimensions (W×H×D) | 220mm × 300mm × 150mm (excluding connectors/heat sinks) |

| Installation Method | Rack mounting (19-inch standard, 3U height) + forced-air cooling (integrated fans) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/electromagnetic standards) |

| Overload Protection | Over-voltage (5500V max), over-current (130mA max), and over-temperature (70°C) |

LAM 810-800082-043

Product Introduction

The LAM 810-800082-043 is a precision high-voltage power supply module developed by LAM Research, a global pioneer in semiconductor manufacturing equipment. Specifically engineered for integration into LAM’s plasma-based processing systems—including Centura® Etch, Sym3® Deposition, and Versys® Metal systems—this module serves as the core power source for generating and sustaining stable plasma during wafer fabrication.

As a flagship model in LAM’s High-Voltage Power Series, the LAM 810-800082-043 is optimized for advanced semiconductor process nodes (down to 3nm) where plasma density and stability directly impact device performance. Its primary function is to deliver highly regulated DC voltage (0–5000V) and current (0–100mA) to plasma chambers, ensuring consistent ion energy and reaction conditions across every wafer. In automation systems, the LAM 810-800082-043 acts as a critical link between the system controller and plasma hardware, enabling real-time adjustments to power parameters and proactive fault detection—key to minimizing process drift and maximizing fab yield.

Core Advantages and Technical Highlights

Ultra-Precise Voltage Regulation: The LAM 810-800082-043 achieves ±0.05% voltage regulation accuracy at full load, a level of precision unmatched by many competing modules. This is enabled by a proprietary closed-loop feedback system that samples output voltage 10,000 times per second, correcting deviations in under 1ms—critical for 3nm/5nm nodes where plasma instability can cause micro-etching defects.

Semiconductor-Grade Durability: Built to comply with SEMI S2/S8/S14 standards, the LAM 810-800082-043 features a ruggedized design that withstands the harsh conditions of semiconductor fabs. Its internal components are coated with a corrosion-resistant film to protect against low-level process gas leaks (e.g., fluorine, chlorine), while integrated heat sinks and variable-speed fans maintain optimal operating temperature—extending the module’s mean time between failures (MTBF) to over 150,000 hours.

Multi-Protocol Connectivity: The LAM 810-800082-043 supports three industry-standard communication protocols (Modbus TCP/IP, Ethernet/IP, Modbus RTU), enabling seamless integration with LAM’s native controllers and third-party automation platforms (e.g., Rockwell Allen-Bradley, Siemens Sinumerik). This flexibility eliminates compatibility barriers, allowing fabs to upgrade legacy systems with the module without replacing entire control architectures.

Proactive Fault Protection: The module includes triple-layer protection (over-voltage, over-current, over-temperature) with customizable thresholds. When a fault is detected, the LAM 810-800082-043 immediately shuts down output, logs the event with time stamps and error codes, and sends alerts via Ethernet/RS-485—reducing the risk of chamber damage or wafer scrapping. Unlike basic modules that require manual resets, it can automatically restart (with user approval) once the fault is resolved, minimizing downtime.

Typical Application Scenarios

The LAM 810-800082-043 is indispensable in semiconductor fabs for plasma-centric processes, with two primary high-impact applications: advanced plasma etching and high-aspect-ratio (HAR) hole formation.

In plasma etching (e.g., for logic or memory device patterning), the LAM 810-800082-043 supplies regulated high voltage to the chamber’s upper electrode, controlling plasma density and ion energy. For 3nm process nodes, this ensures that etched features (e.g., gate trenches) have vertical sidewalls and minimal line-edge roughness—critical for reducing device leakage current. Fabs using LAM’s Centura® Etch systems rely on the LAM 810-800082-043 to maintain consistent plasma conditions across 200mm/300mm wafers, even during 24/7 high-volume production.

In HAR hole formation (used in 3D NAND or DRAM devices), the LAM 810-800082-043 delivers stable low-current (20–50mA) high voltage (3500–4500V) to etch deep, narrow holes (aspect ratios >100:1) in dielectric layers. Its precise current control prevents hole tapering or bottom rounding, while its over-voltage protection safeguards the expensive chamber electrodes from damage. The module’s compliance with SEMI S14 (electromagnetic compatibility) also ensures it does not interfere with sensitive wafer metrology tools in Class 1 cleanrooms.

LAM 810-800082-043

Related Model Recommendations

LAM 810-800082-044: An upgraded variant of the LAM 810-800082-043 with higher output voltage (0–6000V) and current (0–150mA), designed for next-gen 2nm process plasma systems.

LAM 810-800081-043: A lower-power companion to the LAM 810-800082-043 (0–3000V, 0–50mA), ideal for R&D labs or low-volume specialty wafer processing (e.g., MEMS).

LAM 810-800083-043: A redundant power supply module that pairs with the LAM 810-800082-043 for fault-tolerant systems (e.g., high-yield memory fabs), automatically switching to backup power if the primary module fails.

LAM 810-800082-042: A legacy replacement for LAM’s pre-2015 high-voltage modules (e.g., 810-800079-001), fully compatible with the LAM 810-800082-043’s mounting and communication protocols.

LAM 810-800090-043: A monitoring accessory module that tracks the LAM 810-800082-043’s output voltage, current, and temperature in real time, sending predictive maintenance alerts via LAM’s FabGuard® software.

LAM 810-800082-045: A compact version of the LAM 810-800082-043 (2U rack height) for space-constrained fabs, maintaining identical voltage regulation and protocol support.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the LAM 810-800082-043, ensure the 19-inch rack meets weight requirements (12kg module + cooling) and has adequate ventilation (minimum 10cm clearance above/below for airflow). Required tools include a torque wrench (for rack mounting, 2.5 N·m torque), multimeter (to verify input voltage), and ESD-safe gloves/wristbands. Safety precautions: Disconnect all AC power to the rack before wiring; use insulated tools when handling high-voltage terminals; and confirm the module’s ground connection (≥10AWG wire) is secure to prevent electrical hazards. Avoid installing near process gas lines to minimize corrosion risk.

Maintenance Suggestions: For daily maintenance, check the LAM 810-800082-043’s front-panel LED indicators (green = normal, amber = warning, red = fault) and clean air intake filters weekly (use compressed air at <50psi). Every 12 months, perform a calibration check using LAM’s CalibrateHV™ tool to verify voltage regulation accuracy—this ensures compliance with SEMI process standards. If a fault occurs (e.g., over-temperature), first review the module’s internal log via Ethernet to identify the root cause (e.g., clogged filter, high load). When replacing parts (e.g., cooling fans), use only LAM-approved components; non-approved parts may compromise safety or void the warranty.

Service and Guarantee Commitment

The LAM 810-800082-043 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and performance under normal use (per SEMI S2/S8 operating conditions). If the module fails within the warranty period, LAM provides a “swap-out” service—delivering a pre-calibrated replacement unit within 24 hours (for Priority Service customers) to minimize fab downtime, with no cost for repair or shipping.

LAM offers end-to-end technical support for the LAM 810-800082-043, including 24/7 access to high-voltage power specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours for global fabs). The module also includes free firmware updates for 5 years post-purchase, ensuring compatibility with future LAM system upgrades and emerging process nodes.

To further enhance reliability, LAM offers a Customized Maintenance Program for the LAM 810-800082-043, which includes scheduled on-site inspections, proactive part replacement, and calibration services tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the LAM 810-800082-043’s quality and its dedication to supporting customers’ most critical semiconductor manufacturing operations.