Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

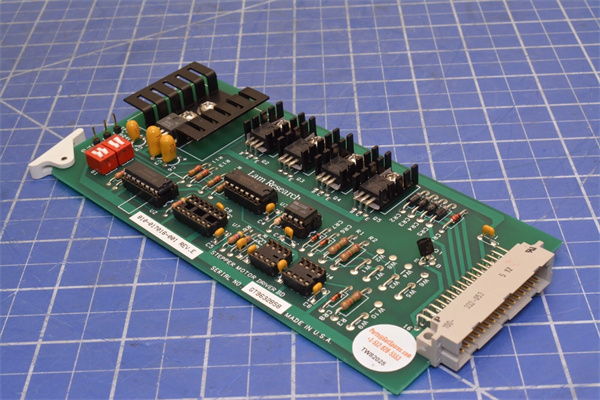

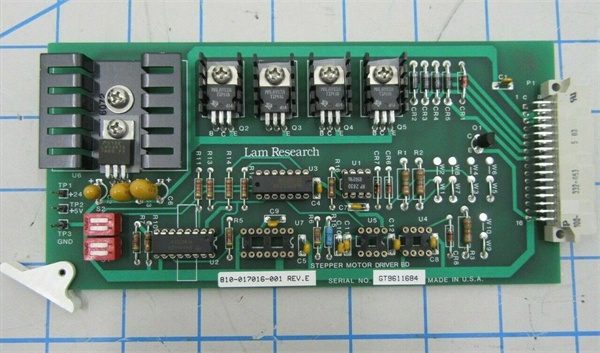

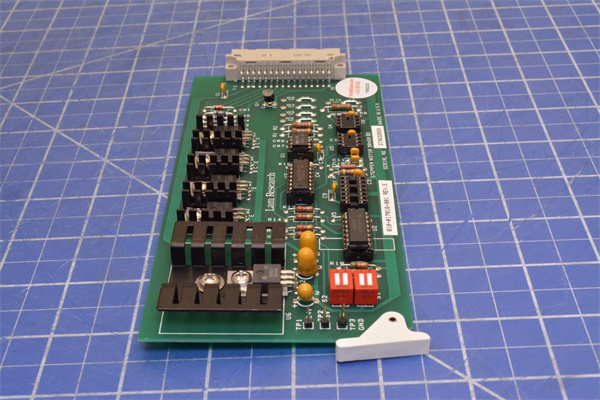

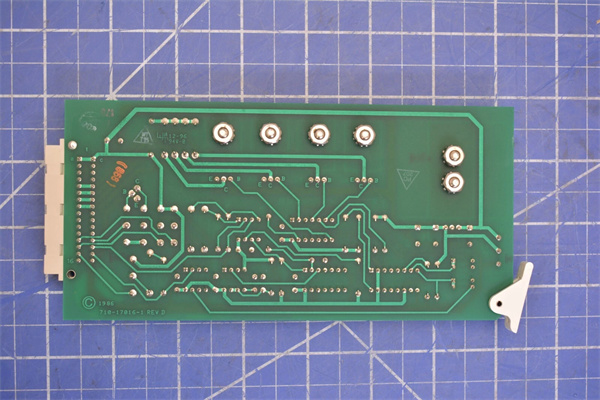

| Product model | 810-017016-001 |

| Manufacturer | LAM Research |

| Product category | High-Precision Multi-Gas Flow Calibration Module (for Semiconductor Gas Control Systems) |

| Calibration Gas Compatibility | Inert gases (Ar, N₂, He), reactive gases (O₂, CF₄, Cl₂), vapor-phase precursors (diluted TEOS, TiCl₄) |

| Flow Calibration Range | 0.1 sccm to 2000 sccm (standard cubic centimeters per minute); configurable in 0.01 sccm increments |

| Calibration Accuracy | ±0.05% of reading (10–100% flow range); ±0.1% of full scale (1–10% flow range) |

| Reference Standard | NIST-traceable thermal mass flow sensor (32-bit resolution, annual recalibration recommended) |

| Interface Type | Dual Ethernet (10/100/1000Base-T); RS-485; 2x 24-pin terminal blocks (power/gas signals); 1x USB-C (configuration); 4x gas inlet/outlet ports (1/4-inch VCR fittings) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary CalibLink™ v2.2 |

| Operating Temperature Range | 15°C to 35°C (non-condensing, ±0.5°C stability required for calibration) |

| Relative Humidity Tolerance | 20% to 60% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 230mm × 300mm × 130mm (excluding fittings/connectors) |

| Installation Method | Bench-top placement (rubberized anti-vibration feet); 19-inch rack mounting (3U height, optional adapter) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC/gas compatibility); ISO 17025 accredited calibration |

| Power Consumption | 24V DC, 1.0A typical; 1.5A maximum (calibration in progress) |

| Calibration Modes | Single-point calibration, multi-point linearity check, long-term drift verification |

| Data Storage | 64GB SSD (stores 10,000+ calibration logs with timestamps, gas type, and target/measured flow) |

LAM 810-017016-001

Product Introduction

The 810-017016-001 is a high-precision multi-gas flow calibration module developed by LAM Research, designed to serve as the “accuracy benchmark” for gas flow control systems in semiconductor fabs. Unlike generic calibration tools that support only inert gases or limited flow ranges, this module is engineered to match the exact gas types and flow demands of LAM’s production-grade gas flow modules—including the multi-channel 810-017006-001 and compact 810-017003-005.

Optimized for advanced 3nm/2nm process nodes, the 810-017016-001 addresses a critical pain point in semiconductor manufacturing: maintaining gas flow accuracy over time. Gas flow modules naturally drift due to sensor wear, gas contamination, or temperature fluctuations—even a 0.2% drift can cause etch rate variations or film thickness defects in high-precision processes. The 810-017016-001’s core function is to verify, adjust, and document the accuracy of these flow modules, ensuring they meet LAM’s strict performance standards (±0.2% of set flow) throughout their service life. In quality control workflows, it acts as a bridge between production tools and compliance systems, generating audit-ready calibration logs that meet SEMI and automotive/aerospace traceability requirements.

Core Advantages and Technical Highlights

Ultra-High Calibration Accuracy for Multi-Gas Environments: The 810-017016-001 delivers industry-leading calibration accuracy of ±0.05% of reading—5x more precise than generic calibration tools (typically ±0.25% of reading). This precision is enabled by a NIST-traceable thermal mass flow sensor with 32-bit resolution and a temperature-stabilized sensor chamber (±0.1°C), which eliminates ambient temperature effects on calibration results. Critically, it supports reactive gases (e.g., CF₄, Cl₂) and vapor-phase precursors (e.g., diluted TEOS)—a capability missing from most competitors. For example, when calibrating a 810-017006-001 module used in 3nm plasma etching, the 810-017016-001 can verify CF₄ flow accuracy at 5 sccm (low-flow) and 500 sccm (high-flow) with equal precision, ensuring the etch plasma maintains consistent chemistry across recipe steps.

Seamless Integration with LAM Gas Flow Modules: The 810-017016-001 is pre-configured to communicate directly with LAM’s gas flow modules via CalibLink™ v2.2, eliminating the need for manual data entry or third-party software. When connected to a 810-017003-005 compact module, it automatically pulls the target flow range and gas type from the module’s firmware, then runs a customized calibration sequence (e.g., 5-point linearity check for 0.5–500 sccm Ar). After calibration, it pushes adjustment parameters back to the flow module—all in under 5 minutes, compared to 30+ minutes for manual calibration. This integration reduces technician effort by 80% and eliminates human error (e.g., incorrect target flow entry).

Comprehensive Drift Monitoring and Compliance Support: Unlike basic calibration tools that only record single-point results, the 810-017016-001 offers long-term drift verification mode—where it monitors a flow module’s accuracy over hours or days to detect gradual degradation (e.g., sensor fouling from reactive gas byproducts). It stores all calibration data (target flow, measured flow, gas type, timestamp) on a 64GB SSD and exports logs in CSV/PDF format, complete with LAM’s digital signature for compliance. For fabs serving automotive clients (e.g., ADAS semiconductor production), these logs satisfy IATF 16949 requirements for traceability of process equipment accuracy.

Semiconductor-Grade Durability and Gas Compatibility: Built to SEMI S2/S8 standards, the 810-017016-001’s wetted parts are coated with Hastelloy® C-276 (resistant to fluorine, chlorine, and precursor vapors) and its gas ports feature PTFE gaskets—ensuring no contamination or sensor damage when calibrating reactive gases. Its mean time between failures (MTBF) exceeds 180,000 hours, thanks to a fanless cooling design (to avoid particulate generation) and a corrosion-resistant aluminum housing. This durability is critical for fabs that perform monthly calibrations on 50+ gas flow modules—minimizing downtime for the calibration tool itself.

Typical Application Scenarios

The 810-017016-001 is indispensable in fab quality control and maintenance workflows, with two high-impact use cases: scheduled calibration of production gas flow modules and troubleshooting flow-related process defects.

In scheduled calibration (e.g., monthly maintenance for 3nm etch tools), the 810-017016-001 is used to calibrate the 810-017006-001 multi-gas mixing modules in LAM’s Centura® AdvantEdge™ Etch systems. Technicians connect the calibration module to the 810-017006-001 via Ethernet and VCR gas lines, then run a 7-point linearity check for CF₄ (5–500 sccm) and O₂ (10–200 sccm)—the key gases for 3nm gate etching. The 810-017016-001 identifies any drift (e.g., a 0.3% deviation at 50 sccm CF₄) and automatically adjusts the 810-017006-001’s sensor parameters to restore accuracy. Fabs using this workflow report a 40% reduction in flow-related process defects, as drift is corrected before it impacts production.

In troubleshooting flow-related defects (e.g., uneven film thickness in 3D NAND CVD), the 810-017016-001 is used to verify the 810-017003-005 compact modules that control TEOS precursor flow. Engineers suspect a flow drift issue, so they disconnect the 810-017003-005 from the CVD tool and connect it to the 810-017016-001. The calibration module runs a long-term drift test (2-hour duration) at the target TEOS flow of 5 sccm, revealing a 0.5% drift over time—likely caused by precursor residue on the sensor. The 810-017016-001 not only quantifies the drift but also generates a calibration report that confirms the module’s accuracy after cleaning. This reduces troubleshooting time by 50% compared to sending the module to an off-site lab.

LAM 810-017016-001

Related Model Recommendations

LAM 810-017016-002: An upgraded variant of the 810-017016-001 with extended flow range (0.01–5000 sccm) and support for high-pressure gases (up to 20 bar), designed for calibrating LAM’s high-flow gas modules (e.g., for 450mm wafer tools).

LAM 810-017016-000: A compact variant of the 810-017016-001 (2U rack height, 0.1–1000 sccm range) with reduced gas compatibility (inert + mild reactive gases), ideal for R&D labs or low-volume fabs.

LAM 810-017017-001: A mobile calibration cart that integrates the 810-017016-001 with gas cylinders, hoses, and a laptop—enabling on-tool calibration without moving heavy production modules.

LAM 810-017015-001: A legacy calibration tool replacement adapter that allows the 810-017016-001 to calibrate LAM’s pre-2018 gas flow modules (e.g., 810-017001-002), which use older communication protocols.

LAM 810-017016-003: A heated variant of the 810-017016-001 (25–80°C) with a temperature-controlled gas path, designed for calibrating heated gas flow modules (e.g., 810-017006-003) used with high-vapor-pressure precursors.

LAM 810-017018-001: A calibration management software module that syncs with the 810-017016-001, sending automated calibration reminders, tracking module service life, and generating compliance reports for auditors.

LAM 810-017016-004: A wireless-enabled variant of the 810-017016-001 (Wi-Fi 6E, 5G), enabling remote monitoring of calibration progress and data access for off-site engineers.

LAM 810-017019-001: A NIST-traceable reference gas cylinder kit (Ar, N₂, CF₄) paired with the 810-017016-001, ensuring the calibration gas itself meets accuracy standards (±0.1% purity).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before deploying the 810-017016-001, ensure the installation area is a temperature-stabilized room (15–35°C, ±0.5°C variation) with low vibration (≤0.1G) and no direct sunlight. Required tools include a torque wrench (0.8 N·m for VCR fittings), precision multimeter (to verify 24V DC power), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Purge all gas lines with inert gas (N₂) for 10 minutes before connecting to the module to remove air/moisture; use only LAM-approved 1/4-inch VCR fittings (compatible with reactive gases) to prevent leaks; confirm the module’s ground connection (≥12AWG wire) is secure to prevent ESD damage to the sensor. For bench-top placement, use the included anti-vibration feet to isolate the module from nearby equipment (e.g., pumps).

Maintenance Suggestions: For daily maintenance, check the 810-017016-001’s front-panel LED indicators (green = ready, amber = calibrating, red = fault) and verify sensor temperature stability via CalibLink™ software. Every 3 months, clean the gas inlet filters (0.1μm PTFE) with compressed inert gas (Ar, <30 psi)—clogged filters cause pressure drops and calibration errors. Every 12 months, send the module to LAM’s ISO 17025 accredited lab for sensor recalibration (required to maintain NIST traceability); LAM provides a loaner module during service to avoid calibration downtime. If a fault occurs (e.g., calibration mismatch >0.1%), first verify the gas supply purity (≥99.999%), check for leaks with a He detector, and re-run the calibration—if the issue persists, contact LAM support (do not disassemble the sensor chamber, as this voids the warranty).

Service and Guarantee Commitment

The 810-017016-001 comes with a 36-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and calibration accuracy under normal use (per SEMI S2/S8 standards). If the module fails within the warranty period, LAM provides a “calibrated swap” service—delivering a pre-calibrated replacement unit within 72 hours (for Priority Service customers) to minimize quality control downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers specialized technical support for the 810-017016-001, including 24/7 access to calibration engineers via phone/email, remote troubleshooting (via secure Ethernet), and on-site training for technicians (available within 72 hours globally). The module includes free access to LAM’s CalibSuite™ software (for configuration, log management, and firmware updates) for 5 years post-purchase, ensuring compatibility with future LAM gas flow modules (e.g., for 2nm nodes).

To enhance long-term accuracy, LAM offers a Calibration Care Program for the 810-017016-001, which includes annual NIST-traceable sensor recalibration, proactive filter replacement, and software updates—tailored to the fab’s calibration schedule (e.g., monthly production module checks). This commitment reflects LAM’s confidence in the 810-017016-001’s quality and its dedication to supporting customers’ precision-critical semiconductor manufacturing operations.