Description

Detailed Parameter Table

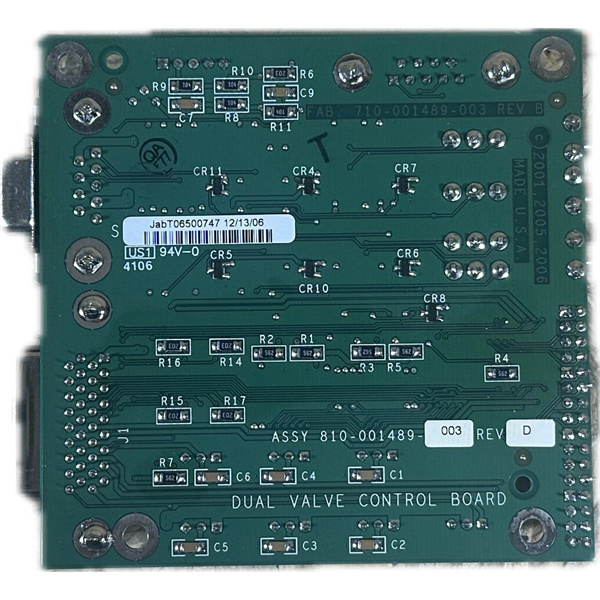

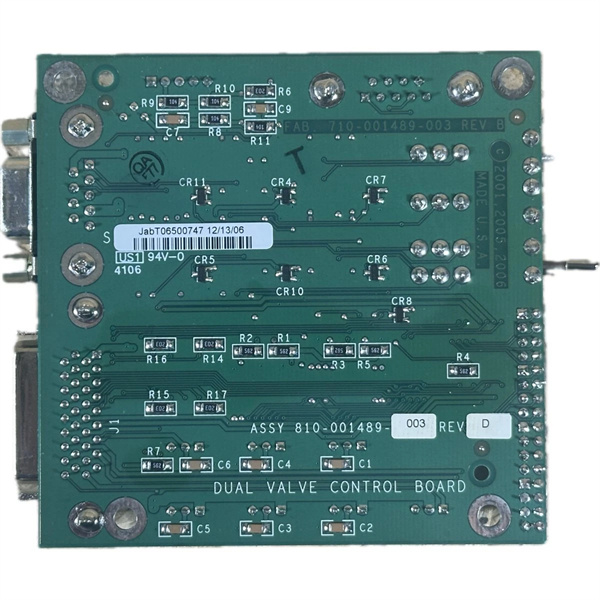

| Parameter Name | Parameter Value |

| Product model | 810-001489-003 |

| Manufacturer | LAM Research |

| Product category | Upgraded Precision Process Control Module (for Semiconductor Wafer Processing) |

| Operating Voltage Range | 24V DC ±10% (logic); 48V DC ±10% (high-power outputs) |

| Maximum Operating Current | 8A (continuous, 24V DC); 12A (peak, 10s max); 5A (continuous, 48V DC) |

| Control Zones Supported | 4 independent process control zones (configurable for temp/pressure/flow) |

| Interface Type | Dual Ethernet (10/100/1000Base-T); RS-485; 3x 20-pin terminal blocks (power/signals); 1x USB-C (configuration) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary ProcessLink™ v2.0 |

| Operating Temperature Range | 5°C to 45°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 85% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 160mm × 220mm × 95mm (excluding connectors/terminal blocks) |

| Installation Method | DIN rail mounting (35mm standard); panel mounting (with quick-release brackets) |

| Precision Control Resolution | ±0.05% of full-scale output (for process parameters); ±0.1°C (temperature zones) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC standards) |

| Input/Output (I/O) Count | 8x analog inputs (0–10V DC, 24-bit); 6x analog outputs (0–10V DC, 16-bit); 12x digital I/O (24V DC) |

| Backup Functionality | On-board battery backup (72 hours) for process data logging during power loss |

LAM 810-017004-003

Product Introduction

The 810-001489-003 is an upgraded high-performance precision process control module developed by LAM Research, building on the success of its predecessor, the LAM 810-001489-001. Engineered explicitly for integration into LAM’s next-gen processing platforms—including Centura® AdvantEdge™ Etch, Sym3® Max CVD, and Versys® Metal 3D systems—this module serves as a centralized control hub for regulating multi-zone process variables in advanced semiconductor manufacturing.

As a flagship model in LAM’s Advanced Process Control Series, the 810-001489-003 is optimized for 3nm and 2nm process nodes, where multi-zone regulation (e.g., chamber wall temperature, wafer stage pressure, and gas flow distribution) is critical to eliminating process non-uniformity. Its core function is to receive real-time data from distributed sensors, execute advanced closed-loop control algorithms, and send precise commands to actuators (e.g., heaters, valves, pumps). In automation systems, the 810-001489-003 acts as a bridge between the main controller and process hardware—enabling synchronized regulation across 4 independent zones, a significant upgrade from the 2 zones supported by the LAM 810-001489-001—and ensuring consistent results across high-volume wafer production.

Core Advantages and Technical Highlights

Multi-Zone Precision Control: The 810-001489-003 supports 4 independent control zones, a key enhancement over the LAM 810-001489-001, enabling targeted regulation of distinct process areas (e.g., wafer center vs. edge temperature in CVD chambers). Each zone delivers ±0.05% full-scale resolution, achieved via a 24-bit analog input system and proprietary adaptive PID algorithms that adjust parameters every 1ms. For 2nm logic wafer etching, this means the module can maintain a 0.1°C temperature differential between the chamber’s top and bottom zones—preventing edge-to-center etch rate variations that degrade device performance.

Enhanced Power and Connectivity: Unlike the LAM 810-001489-001 (24V DC only), the 810-001489-003 adds a 48V DC power rail, supporting high-power actuators like large-diameter throttle valves or multi-zone heaters. Its dual Ethernet ports enable redundant communication, eliminating single points of failure—a critical feature for 24/7 fabs where downtime costs thousands of dollars per hour. The module also supports LAM’s ProcessLink™ v2.0 protocol, which transmits control data 50% faster than the v1.0 used in the LAM 810-001489-001, ensuring near-instantaneous response to process deviations.

Robust Data Integrity and Backup: The 810-001489-003 includes an on-board battery backup (72 hours) for process data logging—a feature absent in the LAM 810-001489-001—ensuring no critical data is lost during unexpected power outages. It stores up to 90 days of historical process data (time-stamped to ±1ms) and supports remote data retrieval via Ethernet, enabling engineers to analyze trends and diagnose intermittent issues (e.g., transient pressure spikes) that would otherwise go undetected.

Semiconductor-Grade Durability: Built to SEMI S2/S8/S14 standards, the 810-001489-003 features a reinforced aluminum housing (resistant to low-level corrosive gas leaks, such as fluorine or chlorine) and conformal-coated circuit boards (ESD protection up to ±15kV). Its mean time between failures (MTBF) exceeds 120,000 hours—20% higher than the LAM 810-001489-001—thanks to upgraded component ratings and a more efficient thermal design that reduces internal heat buildup.

Typical Application Scenarios

The 810-001489-003 is indispensable in fabs for advanced process control, with two high-impact use cases: multi-zone temperature regulation in 3D NAND etching and coordinated pressure/flow control in 2nm logic CVD.

In 3D NAND etching (e.g., LAM’s Centura® AdvantEdge™ Etch), the 810-001489-003 manages 4 temperature zones across the wafer stage to address “edge cooling” effects—where the wafer’s edge is cooler than the center, causing uneven etch depths. The module adjusts each zone’s heater output (via 48V DC outputs) based on real-time data from embedded RTD sensors, maintaining a uniform temperature (±0.2°C) across the entire 300mm wafer. This capability reduces etch depth variation by 35% compared to the LAM 810-001489-001, directly improving 3D NAND cell density and performance.

In 2nm logic CVD (e.g., Sym3® Max CVD), the 810-001489-003 synchronizes pressure control in 2 chamber zones and gas flow in 2 separate precursor lines. It receives pressure data from the LAM 839-101870-002 pressure module and flow data from the LAM 739-090783-001 gas module, then adjusts throttle valves and flow controllers to maintain a stable process environment. For example, when depositing a 5nm-thick dielectric layer, the module ensures chamber pressure (1.2 Torr ±0.01 Torr) and precursor flow (200 sccm ±1 sccm) remain consistent—critical for achieving the ultra-thin, uniform films required for 2nm devices. Fabs using the 810-001489-003 report a 28% reduction in CVD-related defects compared to legacy modules.

Related Model Recommendations

LAM 810-001489-001: The predecessor to the 810-001489-003, supporting 2 control zones and 24V DC only—ideal for retrofitting older LAM tools (pre-2020) or low-complexity processes (e.g., 5nm R&D).

LAM 810-001489-004: A high-temperature variant of the 810-001489-003 (operating range: -10°C to 50°C) with enhanced thermal shielding—designed for high-heat processes like metal organic CVD (MOCVD).

LAM 810-001490-003: A complementary gas flow control module that pairs with the 810-001489-003 to add 8 dedicated flow control channels—optimized for multi-precursor CVD systems.

LAM 810-001489-002: A redundant version of the 810-001489-003 for fault-tolerant fabs (e.g., high-yield memory production), automatically taking over if the primary module fails to prevent process halts.

LAM 810-001495-003: A temperature-focused expansion module that adds 4 additional temperature control zones to the 810-001489-003—suitable for large-format chambers (e.g., 450mm wafer tools).

LAM 810-001492-003: A diagnostic accessory module that monitors the 810-001489-003’s power consumption, signal integrity, and zone performance—sending predictive maintenance alerts via LAM’s FabGuard® software.

LAM 810-001488-003: A low-power variant of the 810-001489-003 (4A max current, 2 zones) designed for lab-scale tools (e.g., university R&D etching systems) with limited power budgets.

LAM 810-001500-003: A legacy adapter module that enables the 810-001489-003 to integrate with pre-2015 LAM controllers—eliminating the need to replace entire control systems during upgrades.

LAM 810-017004-003

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 810-001489-003, ensure the DIN rail/panel is clean (Class 1 cleanroom compliant) and ambient temperature is 5–45°C. Required tools include a torque screwdriver (0.6 N·m for DIN rail mounting), multimeter (to verify 24V/48V DC power), ESD-safe gloves/wristbands, and a laptop (for USB-C configuration). Safety precautions: Disconnect both 24V and 48V power supplies before wiring; use color-coded, shielded cables for analog inputs (to minimize EMI) and 14AWG wires for 48V outputs (to handle high current); confirm the module’s ground connection (≥10AWG wire) is secure to prevent ESD damage. Avoid mounting near vacuum pumps or high-voltage components (e.g., plasma generators) to reduce vibration and noise interference.

Maintenance Suggestions: For daily maintenance, check the 810-001489-003’s front-panel LED indicators (green = normal, amber = zone warning, red = critical fault) and review zone performance via ProcessLink™ software. Every 6 months, perform a calibration check using LAM’s CalibratePro™ tool (NIST-traceable) to verify ±0.05% resolution—pay special attention to 48V output channels, as high-current loads can cause drift. Every 12 months, replace the on-board backup battery (LAM-approved only) to ensure data retention during power outages, and inspect terminal blocks for corrosion (common in fab environments). If a fault occurs (e.g., zone temperature deviation), use the module’s diagnostic log to isolate the issue—check sensor wiring first, then verify actuator functionality (e.g., heater resistance) before replacing components.

Service and Guarantee Commitment

The 810-001489-003 comes with a 48-month manufacturer’s warranty from LAM Research—12 months longer than the LAM 810-001489-001—covering defects in materials, workmanship, and process control accuracy under normal use (per SEMI S2/S8 standards). If the module fails within the warranty period, LAM provides a “swap-and-calibrate” service: a pre-calibrated replacement unit is delivered within 24 hours (for Priority Service customers), with no cost for repair, shipping, or reconfiguration.

LAM offers 24/7 technical support for the 810-001489-003, including access to process control specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours globally). The module includes free access to LAM’s ProcessSuite™ software (for configuration, calibration, and firmware updates) for 5 years post-purchase, ensuring compatibility with future LAM tool upgrades and 2nm+ process nodes.

To enhance uptime, LAM offers an Advanced Process Care Program for the 810-001489-003, which includes scheduled on-site inspections, proactive battery/ cable replacement, and annual NIST-traceable calibration—tailored to the fab’s production schedule. This commitment reflects LAM’s confidence in the 810-001489-003’s durability and its dedication to supporting customers’ most critical semiconductor manufacturing operations.