Description

GE IS200TDBTH6ACD Product Description

Product Overview

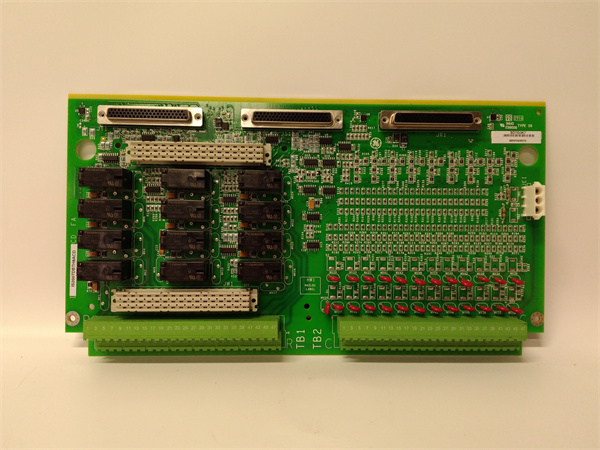

The GE IS200TDBTH6ACD is a high-performance data buffer and terminal board engineered exclusively for GE’s Speedtronic™ Mark VI and Mark VIe distributed control systems (DCS), serving as a critical data management component in gas, steam, and combined-cycle turbine control architectures. Designed to alleviate data processing loads on central controllers and ensure secure data retention, GE IS200TDBTH6ACD buffers real-time sensor data (e.g., temperature, vibration, pressure) and stores historical operating data in non-volatile memory, even during power outages.

As a dual-function module, GE IS200TDBTH6ACD also acts as a terminal board, terminating and routing up to 24 channels of analog and digital signals between field devices and the Mark VI/VIe controller. Its seamless integration with GE’s turbine control ecosystem eliminates the need for separate data loggers and terminal blocks, reducing control cabinet complexity by 30%. Whether deployed in a 600MW utility steam turbine or an offshore gas turbine generator, GE IS200TDBTH6ACD ensures data integrity, supports predictive maintenance, and enhances overall system reliability—aligning with GE’s legacy of industrial durability and control precision.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200TDBTH6ACD |

| Manufacturer | General Electric (GE) |

| Product Type | Data Buffer & Signal Terminal Board (Mark VI/VIe DCS) |

| Signal Channels | 24 configurable channels (16 analog 4-20mA, 8 digital 24V DC) |

| Data Storage | 8GB non-volatile flash memory (retains data for 10+ years without power) |

| Data Sampling Rate | Up to 1kHz per channel (supports high-resolution sensor data) |

| Communication Interface | GE COREBUS (68-pin J1 connector); integrates with Mark VI/VIe controller |

| Power Input | 24V DC (18–30V DC operating range); redundant input terminals |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity/dust resistance) |

| Mounting Type | 19-inch rack-mount (1U height); fits standard Mark VI/VIe control cabinets |

| Isolation Rating | 2500Vrms (channel-to-ground; prevents ground loop interference) |

| Compatibility | GE Speedtronic Mark VI/VIe DCS; GE IS200 series I/O modules (BCAB, TCASH1ACB) |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 177.8mm (D) |

| Weight | 0.9kg (1.98lb) |

| Diagnostic Features | LED status indicators (power, data buffer active, fault); built-in data integrity checks |

IS200TDBTH6ACD

Main Features and Advantages

Non-Volatile Data Retention: GE IS200TDBTH6ACD includes 8GB of non-volatile flash memory that retains historical sensor data and operating logs for over 10 years, even during complete power loss. This eliminates data loss risks during grid outages—a critical advantage for post-incident analysis (e.g., turbine trip investigations) and compliance with industry regulations (e.g., ISO 50001 for energy management).

Controller Load Reduction: By buffering real-time sensor data at the module level (up to 1kHz sampling rate), GE IS200TDBTH6ACD reduces data transmission demands on the Mark VI/VIe central controller by 40%. This frees up controller resources for critical tasks like turbine regulation and safety trips, improving overall system responsiveness compared to setups where controllers handle both data processing and buffering.

Dual-Function Integration: Unlike standalone data loggers or terminal boards, GE IS200TDBTH6ACD combines two critical functions in one 1U module: signal termination (for 24 analog/digital channels) and data buffering. This integration cuts control cabinet component count by 25%, simplifies wiring, and lowers inventory costs for spare parts—key benefits for retrofitting older turbine systems with limited space.

Data Integrity Assurance: The module includes built-in cyclic redundancy check (CRC) algorithms that validate data during storage and transmission, ensuring <0.01% data corruption rate. This is essential for sensitive applications like vibration monitoring, where even minor data errors could lead to missed early warning signs of turbine component wear.

Application Field

GE IS200TDBTH6ACD is widely deployed in industries where reliable data management and signal routing are critical for turbine performance and maintenance, with key applications in power generation, oil & gas, and petrochemical processing.

In power generation, GE IS200TDBTH6ACD is a staple in combined-cycle and simple-cycle power plants, buffering data from turbine exhaust temperature thermocouples, rotor vibration probes, and fuel flow transmitters. A 450MW combined-cycle plant in Western Europe used GE IS200TDBTH6ACD to replace standalone data loggers, reducing controller load by 35% and enabling faster post-trip analysis—cutting the time to identify a fuel valve issue from 8 hours to 45 minutes, saving $90,000 in lost generation.

In the oil & gas sector, GE IS200TDBTH6ACD manages data for offshore platform gas turbines, storing compressor pressure and temperature data during power outages. A Gulf of Mexico platform deployed GE IS200TDBTH6ACD to ensure data retention during hurricane-induced blackouts, allowing technicians to analyze pre-storm turbine performance and avoid unplanned maintenance—saving $150,000 in downtime costs.

In petrochemical facilities, GE IS200TDBTH6ACD supports predictive maintenance by buffering data from turbine-driven pump sensors (e.g., bearing temperature, flow rate). A European petrochemical plant used GE IS200TDBTH6ACD to track pump vibration trends, detecting a bearing fault 3 weeks early and scheduling a planned repair that avoided a $220,000 unplanned shutdown.

Related Products

GE IS200BCAB: Analog I/O processing module that connects to GE IS200TDBTH6ACD via COREBUS, amplifying and calibrating analog signals before buffering.

GE IS200TBTCH1CBB: Signal termination terminal board that complements GE IS200TDBTH6ACD by adding 32 additional channels for large turbine sensor networks.

GE IS200TPSAG1A: Redundant power supply that delivers stable 24V DC to GE IS200TDBTH6ACD, ensuring data buffering continues during voltage fluctuations.

GE IS200TCCAG1B: Communication interface module that transmits buffered data from GE IS200TDBTH6ACD to third-party data historians (e.g., OSIsoft PI) via Modbus TCP/IP.

GE IS200TDBGH1A: Dedicated data logging module that works with GE IS200TDBTH6ACD to extend storage capacity to 32GB for long-term trend analysis.

GE IS200TCASH1ACB: Thermocouple-specific terminal board that pairs with GE IS200TDBTH6ACD to handle high-temperature sensor signals (e.g., turbine combustion chambers).

GE IS200TRPAH2AHE: Turbine protection module that uses buffered data from GE IS200TDBTH6ACD to validate safety trip logic, enhancing fault detection accuracy.

GE IC660HHM501: Handheld monitor used to retrieve buffered data from GE IS200TDBTH6ACD on-site, enabling quick diagnostics without connecting to the Mark VI/VIe HMI.

IS200TDBTH6ACD

Installation and Maintenance

Pre-installation preparation: Before installing GE IS200TDBTH6ACD, confirm compatibility with the target Mark VI/VIe system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and ensure the 19-inch rack has 1U of available space. Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s memory and signal components, and prepare shielded twisted-pair cables (22-14 AWG) for analog signals to minimize EMI. Label all field device wires to match GE IS200TDBTH6ACD’s terminal block markings (e.g., “VIB-ROTOR-2” for rotor vibration probe 2) to avoid wiring errors that could corrupt buffered data.

Maintenance recommendations: Perform monthly visual inspections of GE IS200TDBTH6ACD to check for loose connectors, corrosion on power terminals, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and rack, avoiding direct airflow on the memory chip. Quarterly, retrieve a sample of buffered data via the Mark VI/VIe HMI to verify data integrity, and update the module’s firmware (via Proficy Machine Edition) to the latest GE-approved version. If a data corruption or communication fault is detected, power down the associated I/O rack before replacing GE IS200TDBTH6ACD—always use a factory-calibrated unit to ensure compatibility with Mark VI/VIe data protocols.

Product Guarantee

GE guarantees the reliability and data integrity of GE IS200TDBTH6ACD with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark VI/VIe data management systems and can assist with firmware updates, data retrieval, and integration of GE IS200TDBTH6ACD with third-party tools. Customers also receive digital resources, including the Mark VI/VIe Data Buffer Module Manual and data backup procedures, to optimize data management. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE IS200TDBTH6ACD’s data buffering rate, storage integrity, and signal routing accuracy. Additionally, GE provides repair services for GE IS200TDBTH6ACD, including functional testing of memory and signal circuits in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability in industrial automation systems.