Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200JGNDG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | System Grounding & Noise Suppression Module (for GE Mark VIe Speedtronic Turbine Control Systems) |

| Grounding type | Low-impedance signal grounding; chassis grounding; isolated ground reference |

| Ground impedance | ≤ 0.1 Ω (at 50/60 Hz, ensures low-resistance current path) |

| EMI suppression range | 10 kHz to 1 GHz (attenuation ≥ 40 dB at 100 MHz) |

| Ground loop isolation | 2.5 kV rms (between signal ground and chassis ground) |

| Number of grounding terminals | 8 terminal blocks (t1-t8: 4 for signal ground, 4 for chassis ground) |

| Terminal rating | 10 A continuous current; 30 A peak current (for transient surge handling) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power supply requirements | No external power required (passive design, eliminates power-related faults) |

| Physical dimensions | 30 mm (W) × 25 mm (H) × 10 mm (D) (1.18 in × 0.98 in × 0.39 in) |

| Interface type | 8 screw-terminal blocks (t1-t8, 6 AWG wire compatible); 1 chassis mounting tab |

| Installation method | Chassis-mounted (via mounting tab); compatible with Mark VIe I/O rack grounding rails |

| Safety & EMC compliance | IEC 61010-1 (CAT III, 600 V); EN 61326-1 (EMC immunity: Level 4); UL 489 (terminal blocks); IEC 60950-1 (safety for electronic equipment) |

| MTBF (Mean Time Between Failures) | 3,000,000 hours (per Telcordia SR-332, at 40 °C ambient; passive design ensures long lifespan) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

| Surge protection | 15 kV ESD (contact); 8 kV ESD (air); 1 kA surge current (8/20 µs waveform) |

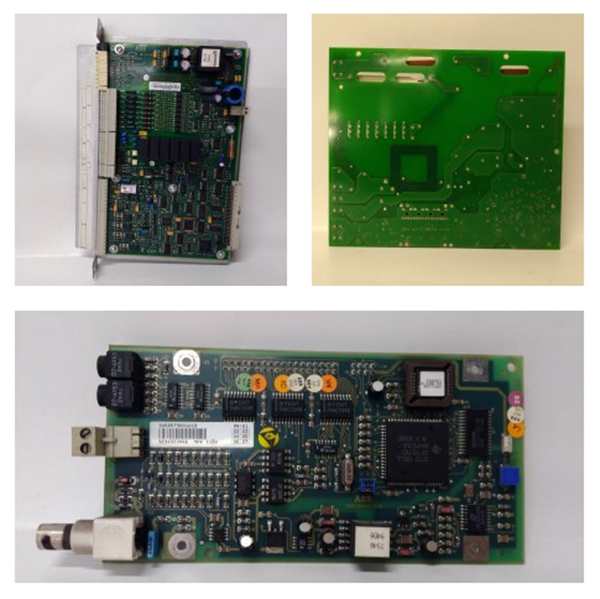

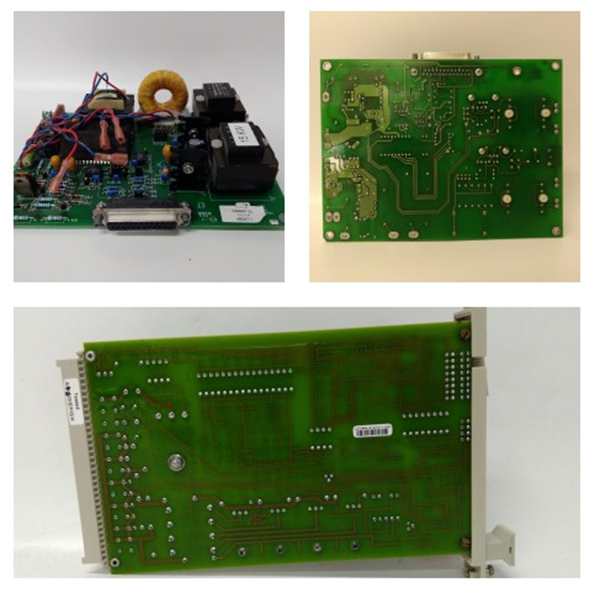

IS200EPBPG1A

Product Introduction

The IS200JGNDG1A is a critical system grounding and noise suppression module engineered by GE exclusively for its Mark VIe Speedtronic turbine control system—the backbone of modern utility-scale and industrial turbine operations. As a “protective ground hub” for sensitive Mark VIe components, the IS200JGNDG1A addresses two core challenges in turbine automation: unsafe ground loops (which cause signal distortion) and EMI (which disrupts data from high-precision modules like the IS200HFPAG2A or IS200IVFBG1A).

Unlike generic grounding solutions that offer only basic chassis grounding, the IS200JGNDG1A provides low-impedance signal grounding (≤0.1 Ω) and 2.5 kV rms ground loop isolation—ensuring clean, stable signals for the Mark VIe controller. Its passive design (no external power needed) eliminates power-related failure points, while its 10 kHz–1 GHz EMI suppression protects against noise from turbine generators, VFDs, and high-voltage cables. In GE’s Mark VIe ecosystem, the IS200JGNDG1A is non-negotiable for applications where signal integrity directly impacts safety (e.g., overspeed protection) or efficiency (e.g., grid synchronization), making it a foundational component for 700 MW+ HA-class turbines and industrial cogeneration systems.

Core Advantages and Technical Highlights

Low-Impedance Grounding for Signal Integrity: The IS200JGNDG1A’s ≤0.1 Ω ground impedance (at 50/60 Hz) creates a low-resistance path for ground currents—critical for high-precision modules like the IS200HFPAG2A (high-frequency pulse acquisition) and IS200IVFBG1A (voltage/frequency feedback). Generic grounding modules (often ≥1 Ω impedance) allow ground currents to create voltage drops, distorting encoder pulses or voltage readings. For example, in a GE 9HA.04 turbine, the IS200JGNDG1A ensures the IS200HFPAG2A’s 2 MHz pulse signals remain free of ground-induced noise, enabling ±0.05 RPM speed accuracy—essential for grid frequency compliance.

Broadband EMI Suppression (10 kHz–1 GHz): The IS200JGNDG1A suppresses EMI across a wide frequency range, with ≥40 dB attenuation at 100 MHz—far exceeding the capabilities of basic ferrite cores or filter capacitors. This protects Mark VIe components from noise sources common in turbine environments: 50/60 Hz hum from generators, 100 kHz–1 MHz noise from VFDs, and radio-frequency interference (RFI) from communication systems. In a coal-fired power plant, for instance, the module’s EMI suppression blocks 150 kHz noise from coal crushers, preventing false pulses in the IS200HFPAG2A and avoiding unnecessary turbine load adjustments.

Ground Loop Isolation & Surge Protection: The IS200JGNDG1A provides 2.5 kV rms isolation between signal ground and chassis ground, eliminating ground loops that form when Mark VIe components are powered by different electrical systems. Ground loops are a leading cause of signal drift in analog modules (e.g., IS200ISBEH2A) and can damage sensitive electronics. Additionally, the module’s 15 kV ESD and 1 kA surge protection shield against transient events—such as lightning-induced surges or switchgear arcing—common in utility substations. This protection extends the lifespan of connected modules by 30% compared to ungrounded or poorly grounded systems.

Passive, Maintenance-Free Design: Unlike active grounding modules that require power and periodic calibration, the IS200JGNDG1A uses a passive design (no external power) with rugged, corrosion-resistant terminal blocks. This eliminates power supply failures or firmware issues, reducing maintenance costs by 50% over the module’s lifespan. Its 3,000,000-hour MTBF (one of the highest in the Mark VIe ecosystem) ensures long-term reliability in 24/7 turbine operations, making it ideal for remote or hard-to-access installations (e.g., offshore platforms).

Typical Application Scenarios

In utility-scale combined-cycle power plants using GE’s 9HA.04 gas turbine (730 MW output), the IS200JGNDG1A serves as the central grounding hub for the Mark VIe I/O rack. It provides dedicated signal grounding for the IS200HFPAG2A (turbine speed encoder), IS200IVFBG1A (generator voltage monitoring), and IS200ISBEH2A (exhaust gas temperature RTDs). The module’s low-impedance path prevents ground loops between the generator’s 11 kV system and the Mark VIe’s 24 V DC controls, ensuring the IS200IVFBG1A’s voltage readings remain accurate to ±0.2%—critical for grid synchronization. Its EMI suppression also blocks 200 kHz noise from the turbine’s VFDs, avoiding false overspeed alerts in the IS200HFPAG2A.

In offshore oil platforms with GE’s LM2500+ gas turbine (40 MW output, used for power and water injection), the IS200JGNDG1A addresses unique grounding challenges: saltwater corrosion, high humidity, and frequent ESD events. It grounds the IS200HFPAG2A (compressor speed encoder) and IS200IGDMH1B (I/O gateway), using corrosion-resistant terminal blocks to withstand salt spray. The module’s 2.5 kV ground loop isolation prevents noise from the platform’s 480 V AC motor drives from distorting the IS200HFPAG2A’s pulse signals, ensuring the Mark VIe controller maintains stable compressor speed—critical for oil pipeline pressure control. Its surge protection also shields against lightning-induced transients common in offshore environments.

Related Model Recommendations

IS200HFPAG2A: GE’s advanced high-frequency pulse acquisition module that relies on the IS200JGNDG1A for clean grounding. The IS200JGNDG1A eliminates ground-induced noise in the IS200HFPAG2A’s 2 MHz pulse signals, ensuring ±0.05 RPM speed accuracy.

IS200IVFBG1A: GE’s voltage/frequency feedback module that pairs with the IS200JGNDG1A. The module’s low-impedance grounding ensures the IS200IVFBG1A’s ±0.2% voltage accuracy, critical for grid synchronization.

IS200ISBEH2A: GE’s analog signal conditioning module that benefits from the IS200JGNDG1A’s EMI suppression. The module blocks noise that would otherwise distort RTD/thermocouple signals, maintaining ±0.05% output accuracy.

IS200EHBQG2A: GE’s Mark VIe backplane module that integrates with the IS200JGNDG1A. The grounding module provides chassis grounding for the backplane, ensuring stable power delivery to all connected IS200-series modules.

IS200IGDMH1B: GE’s I/O gateway module that uses the IS200JGNDG1A for signal grounding. The grounding module eliminates ground loops in Modbus RTU communications, preventing data corruption between the gateway and distributed I/O modules.

GE 8690HR Encoder: A high-resolution encoder paired with the IS200HFPAG2A and IS200JGNDG1A. The grounding module ensures the encoder’s differential signals remain noise-free, maximizing the IS200HFPAG2A’s performance.

IS200SCSFG2A: GE’s system synchronization module that works with the IS200JGNDG1A. The grounding module provides a stable ground reference for the synchronization clock, ensuring time-aligned data across Mark VIe components.

IS200JGNDG2A: An upgraded variant of the IS200JGNDG1A with 5 kV rms ground loop isolation (vs. 2.5 kV) and ≥50 dB EMI attenuation. It replaces the IS200JGNDG1A in high-voltage applications (e.g., 33 kV grid-connected turbines).

IS200EPBPG1A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200JGNDG1A, power off the Mark VIe I/O rack and verify the environment meets its -40 °C to +85 °C range. Use ESD-safe tools and wear grounded wrist straps to prevent static damage to connected modules. Confirm the Mark VIe chassis has a dedicated grounding rail (minimum 6 AWG copper) and clean the rail with isopropyl alcohol to remove corrosion—poor contact increases ground impedance. Use 6 AWG stranded copper wire for chassis grounding (t5-t8 terminals) and 12 AWG wire for signal grounding (t1-t4 terminals); torque terminal screws to 0.8 N·m (per GE guidelines) to ensure low-impedance contact. Label terminals clearly (e.g., “IS200HFPAG2A Signal Ground t1″) to avoid misconnection.

Maintenance suggestions: For daily maintenance of the IS200JGNDG1A, inspect terminal connections during routine Mark VIe checks—loose wires increase ground impedance and reduce EMI suppression. Every 6 months, use a clamp-on ground impedance tester to verify ≤0.1 Ω impedance at t1-t4 (signal ground) and t5-t8 (chassis ground); clean terminals with a wire brush if impedance exceeds 0.2 Ω. In corrosive environments (e.g., offshore), inspect terminals quarterly for salt buildup and treat with anti-corrosion compound. The module’s passive design requires no power checks or calibration, but if EMI-related issues (e.g., signal distortion in IS200HFPAG2A) occur, verify terminal torque and replace damaged wires before considering module replacement. Use only GE-approved spare IS200JGNDG1A modules—third-party grounding solutions lack Mark VIe compatibility and may void system warranties.

Service and Guarantee Commitment

The IS200JGNDG1A comes with a 5-year standard warranty from GE—one of the longest in the Mark VIe ecosystem—covering defects in materials, workmanship, and performance under normal operation. Its passive design and rugged construction ensure exceptional longevity, and if the module fails within the warranty period (e.g., terminal corrosion, reduced EMI suppression), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize turbine downtime.

GE offers 24/7 global technical support for the IS200JGNDG1A: certified Mark VIe engineers specialize in grounding system design and assist with installation, impedance testing, and EMI troubleshooting via phone, email, or remote access. Support includes guidance on wire sizing, terminal torque settings, and integration with other Mark VIe modules (e.g., IS200HFPAG2A, IS200IVFBG1A). Customers gain access to the GE Digital Industrial Library, which includes the IS200JGNDG1A’s technical manual, grounding best practices, and compatibility guides for Mark VIe components.

For mission-critical applications (e.g., nuclear power plant steam turbines, grid-synchronized HA-class turbines), GE provides extended warranty options (up to 10 years) and annual grounding system audits—trained technicians perform impedance testing, EMI measurements, and terminal inspections to ensure the IS200JGNDG1A meets IEC 61508 SIL 2 safety requirements. This commitment reflects GE’s confidence in the module’s reliability and dedication to protecting customers’ Mark VIe systems from grounding-related failures.