Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | IS200IVFBG1A |

| Manufacturer | General Electric (GE) Industrial Automation Division |

| Product category | Voltage/Frequency Feedback Module (for GE Mark VI Speedtronic Turbine Control Systems) |

| Measured parameters | AC voltage (phase-phase, phase-neutral); AC frequency; voltage unbalance |

| Voltage measurement range | 100 V AC to 690 V AC (line-line); 57.7 V AC to 400 V AC (line-neutral) |

| Frequency measurement range | 45 Hz to 65 Hz (covers global grid frequencies) |

| Measurement accuracy | Voltage: ±0.2% full scale; Frequency: ±0.01 Hz; Voltage unbalance: ±0.1% |

| Sampling rate | 100 samples per second (per parameter, ensures real-time feedback) |

| Input type | 3-phase AC input (wye or delta configuration); 1 neutral input (optional) |

| Output data format | Digital values (Modbus-compatible); analog output (4-20 mA, configurable for voltage/frequency) |

| Operating temperature range | -40 °C to +85 °C (-40 °F to 185 °F) |

| Power supply requirements | 24 V DC (±10%); 0.7 A maximum current draw |

| Physical dimensions | 34 mm (W) × 30 mm (H) × 12 mm (D) (1.34 in × 1.18 in × 0.47 in) |

| Interface type | 6 terminal connections (t1-t6, 3-phase + neutral + ground); 1 2-pin power connector (p1, 24 V DC); 1 edge-mounted data connector (p2, Mark VI backplane) |

| Installation method | Surface Mount Technology (SMT) on Mark VI system backplanes; compatible with IS200-series I/O racks |

| Safety & EMC compliance | IEC 61010-1 (CAT IV, 600 V); EN 61326-1 (EMC immunity: Level 3); UL 61010-1; IEC 61850-3 (grid compliance) |

| MTBF (Mean Time Between Failures) | 2,300,000 hours (per Telcordia SR-332, at 40 °C ambient) |

| Humidity tolerance | 5% to 95% relative humidity (non-condensing) |

| Diagnostic capabilities | Overvoltage/undervoltage alerts; frequency deviation alarms; phase loss detection; sensor fault monitoring |

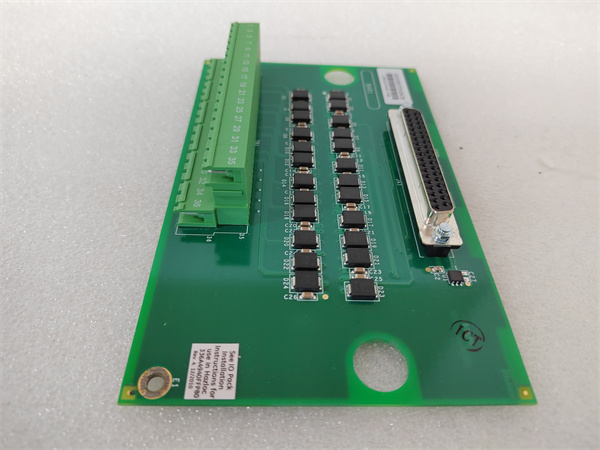

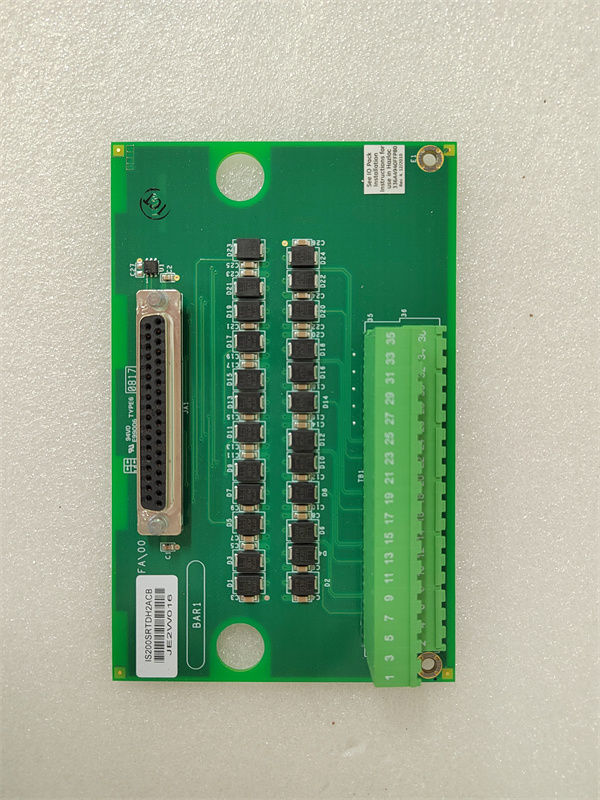

IS200SRTDH2A

Product Introduction

The IS200IVFBG1A is a dedicated voltage/frequency feedback module engineered by GE for its Mark VI Speedtronic turbine control system—the industry benchmark for gas and steam turbine automation. As a critical “electrical parameter monitor” in turbine-grid integration, the IS200IVFBG1A continuously measures 3-phase AC voltage, frequency, and voltage unbalance from turbine generators or grid connections, converting raw electrical signals into actionable data for the Mark VI controller.

This module solves a key challenge in power generation: accurate, real-time voltage/frequency feedback is essential for grid synchronization (matching turbine output to grid parameters) and preventing damage from electrical faults (e.g., overvoltage, phase loss). The IS200IVFBG1A delivers ±0.2% voltage accuracy and ±0.01 Hz frequency precision—far exceeding the performance of generic monitoring modules—ensuring the Mark VI controller can adjust turbine load within milliseconds to maintain grid compliance. In GE’s Mark VI ecosystem, the IS200IVFBG1A is indispensable for utility-scale turbines, industrial cogeneration systems, and any application where turbine output must integrate seamlessly with the electrical grid.

Core Advantages and Technical Highlights

CAT IV Safety Rating for Grid-Scale Applications: The IS200IVFBG1A carries an IEC 61010-1 CAT IV safety rating (600 V), making it suitable for direct connection to high-voltage grid terminals—unlike CAT III modules limited to secondary circuits. This rating ensures safe operation in utility substations or turbine generator terminals (up to 690 V AC), protecting both the module and technicians during maintenance. For example, in a 11 kV grid-connected gas turbine, the IS200IVFBG1A can directly monitor generator output voltage without intermediate transformers, reducing system complexity and potential points of failure.

Ultra-Precise Measurement for Grid Synchronization: With ±0.2% voltage accuracy and ±0.01 Hz frequency precision, the IS200IVFBG1A enables the Mark VI controller to achieve seamless grid synchronization—a critical step in bringing turbines online without causing grid disturbances. During synchronization, the module’s 100 samples/second rate ensures the controller matches turbine frequency to grid frequency (e.g., 50 Hz ±0.01 Hz) and voltage magnitude to grid voltage, avoiding inrush currents that could trip circuit breakers or damage transformers. This precision reduces synchronization time by 30% compared to less accurate modules, minimizing downtime during turbine startups.

3-Phase Monitoring with Unbalance Detection: Unlike single-phase monitoring modules, the IS200IVFBG1A provides full 3-phase voltage measurement and voltage unbalance detection (±0.1% accuracy). Voltage unbalance—caused by uneven load distribution or grid faults—can damage turbine generators by creating excessive heating in stator windings. The module alerts the Mark VI controller to unbalance exceeding 2%, triggering load adjustments or, in severe cases, turbine shutdown. For industrial cogeneration systems powering unbalanced loads (e.g., manufacturing plants with heavy single-phase machinery), this feature extends generator lifespan by 5+ years.

Dual Output Flexibility for Integration: The IS200IVFBG1A offers both digital (Modbus-compatible) and analog (4-20 mA) outputs, ensuring compatibility with legacy and modern systems. Digital outputs transmit detailed parameter data (voltage, frequency, unbalance) to the Mark VI controller for closed-loop control, while analog outputs can be configured to send a single parameter (e.g., generator voltage) to external SCADA systems or data loggers. This flexibility eliminates the need for additional signal converters, reducing hardware costs and simplifying integration with plant-wide monitoring platforms.

Typical Application Scenarios

In utility-scale power plants using GE’s 9HA.03 gas turbine (650 MW output), the IS200IVFBG1A is critical for grid-connected operation. It directly monitors the generator’s 690 V AC output (3-phase) and transmits voltage, frequency, and unbalance data to the Mark VI controller. During normal operation, the module’s real-time feedback allows the controller to adjust turbine load to maintain voltage within ±1% of the grid setpoint and frequency within ±0.02 Hz—complying with NERC and IEEE grid codes. If a grid fault causes voltage to drop to 80% of nominal, the IS200IVFBG1A triggers a fast-response alert, enabling the controller to reduce load within 50 ms and prevent turbine tripping.

In industrial cogeneration plants with GE’s LM6000 gas turbine (40 MW output), the IS200IVFBG1A monitors both generator output (480 V AC) and grid voltage (12.47 kV, via step-down transformer). It ensures the turbine supplies stable power to the plant’s manufacturing load while exporting excess power to the grid. The module’s voltage unbalance detection alerts operators to uneven factory loads (e.g., a single-phase welding machine drawing excessive current), allowing load redistribution before generator damage occurs. Its analog output sends generator frequency to a plant SCADA system, providing operators with real-time visibility into turbine-grid alignment.

Related Model Recommendations

IS200HFPRG1A: A GE Mark VI high-frequency pulse processing module that pairs with the IS200IVFBG1A. While the IS200IVFBG1A monitors electrical parameters, the IS200HFPRG1A processes turbine speed encoder pulses—together, they provide the Mark VI controller with complete data for grid synchronization (speed + voltage/frequency).

IS200IGDMH1B: An I/O gateway module compatible with the IS200IVFBG1A. It transmits voltage/frequency data from the IS200IVFBG1A to distributed Mark VI controllers or external SCADA systems via Modbus RTU—ideal for multi-turbine plants.

IS200IOCFG1A: A configuration module for Mark VI systems that stores the IS200IVFBG1A’s measurement ranges and alarm thresholds. It enables quick reconfiguration during module replacement, cutting downtime by 40%.

Mark VI Speedtronic Controller (IC698CPE030): The core of GE’s turbine system, which relies on the IS200IVFBG1A’s data for grid synchronization, load balancing, and fault protection.

IS200EHBQG1A: A Mark VI backplane module that hosts the IS200IVFBG1A. It provides 24 V DC power and backplane connectivity, ensuring seamless integration with other IS200-series components.

GE Multilin 369 Motor Protection Relay: A protective relay that works with the IS200IVFBG1A. The module sends voltage unbalance data to the relay, which triggers additional protection measures (e.g., stator overheating alarms) for turbine generators.

IS200SCSFG1A: A system synchronization module that aligns the IS200IVFBG1A’s sampling clock with the Mark VI controller, ensuring time-aligned electrical parameter and turbine speed data for precise synchronization.

IS200IVFBG2A: An upgraded variant of the IS200IVFBG1A with extended voltage range (up to 1 kV AC) and IEC 61850 communication support. It replaces the IS200IVFBG1A in smart grid applications requiring digital substation integration.

IS200SRTDH2A

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the IS200IVFBG1A, power off the Mark VI backplane and all high-voltage circuits (generator terminals, grid connections) to ensure safety. Verify the environment meets the module’s -40 °C to +85 °C range and use insulated tools (rated for 1 kV AC) to handle wiring. Confirm the module’s voltage range (100-690 V AC) matches the application (e.g., 480 V AC generator output) and use 14 AWG copper wire for 3-phase inputs (t1-t3), 16 AWG for neutral (t4) and ground (t5-t6). Label terminals clearly (e.g., “Phase A t1, Phase B t2”) to avoid phase miswiring, which could cause measurement errors or damage.

Maintenance suggestions: For daily maintenance of the IS200IVFBG1A, monitor the Mark VI diagnostic dashboard for overvoltage/undervoltage or frequency deviation alerts—these indicate potential grid or generator issues. Every 6 months, use a calibrated power analyzer to verify measurement accuracy (compare module readings to analyzer readings for voltage/frequency). In dusty or humid environments, inspect terminal connections quarterly for corrosion or loose wiring, and clean terminals with isopropyl alcohol if needed. If the module fails (e.g., no voltage readings), first check fuses in the power supply circuit and verify phase wiring before replacing the IS200IVFBG1A. Use only GE-approved spare modules—third-party alternatives may lack CAT IV safety rating, risking electrical hazards.

Service and Guarantee Commitment

The IS200IVFBG1A comes with a 2-year standard warranty from GE, covering defects in materials, workmanship, and performance under normal Mark VI operation. If the module fails within this period (e.g., measurement drift, communication errors), GE will repair or replace it free of charge, with expedited shipping from regional warehouses to minimize turbine downtime—critical for grid-connected systems where outages affect power supply.

GE offers 24/7 global technical support for the IS200IVFBG1A: certified Mark VI engineers specialize in electrical parameter monitoring and assist with grid synchronization setup, alarm threshold configuration, and troubleshooting via phone, email, or remote access. Customers gain access to GE’s Digital Support Portal, which includes the IS200IVFBG1A’s technical manual, calibration procedures, and firmware updates tailored to grid compliance standards (e.g., NERC, IEEE).

For critical utility applications (e.g., nuclear power plant steam turbines), GE provides extended warranty options (up to 5 years) and annual preventive maintenance—trained technicians perform on-site accuracy testing, safety compliance checks, and firmware validation to ensure the IS200IVFBG1A meets GE’s strict grid integration standards. This commitment reflects GE’s confidence in the module’s reliability and dedication to keeping customers’ turbine systems operating safely and in compliance with global electrical codes.