Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

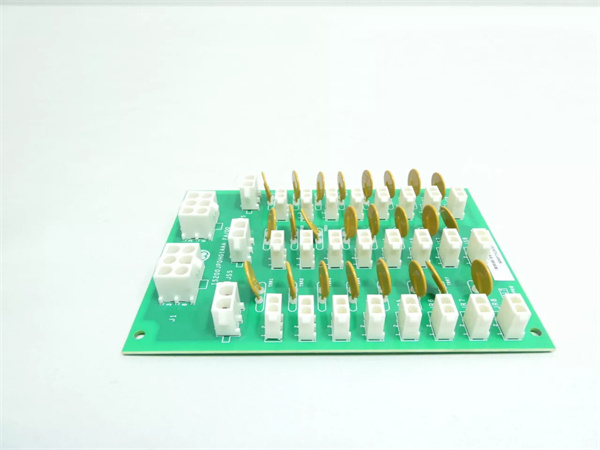

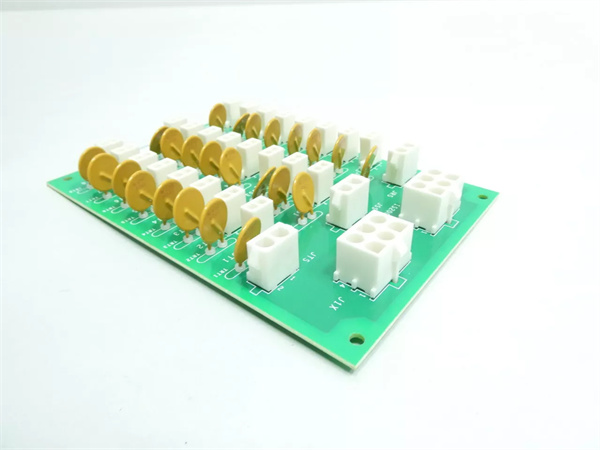

| Product model | IS200GGXIG1A |

| Manufacturer | General Electric (GE) |

| Product category | High-Speed Signal Processing & Isolation Module (Mark VI Speedtronic Turbine Control Series) |

| Signal channels | 8 dual-purpose channels (4 analog input/output + 4 digital input/output, software-configurable) |

| Analog signal range | ±10 V DC (input); 0–24 V DC (output); 12-bit resolution (sampling/ conversion) |

| Digital signal standard | TTL/CMOS (5 V); dry contact input support (0–30 V DC) |

| Isolation voltage | 500 Vrms (channel-to-channel); 1000 Vrms (channel-to-ground) |

| Signal bandwidth | DC to 1 MHz (analog); up to 10 MHz (digital) |

| Sampling rate | 1 MS/s per analog channel (simultaneous sampling) |

| Communication interface | GE backplane bus (for Mark VI controller integration) + 2x terminal blocks (signal I/O) |

| Operating temperature range | -20 °C to 70 °C (-4 °F to 158 °F) |

| Storage temperature range | -40 °C to 85 °C (-40 °F to 185 °F) |

| Physical dimensions | 177.8 mm × 203.2 mm × 30.5 mm (7 in × 8 in × 1.2 in) [GE Mark VI chassis standard] |

| Weight | 385.6 g (13.6 oz) |

| Protection features | Overvoltage protection (±15 V clamp); ESD protection (±15 kV air discharge); short-circuit protection |

| Coating | IPC-CC-830 Class 3 enhanced conformal coating (chemical/ moisture/ salt spray resistance) |

| Compliance standards | UL 508, IEC 61010-1, IEC 61326-1 (EMC), RoHS 3 |

| Compatibility | GE Mark VI/VIe Speedtronic turbine control systems (gas/steam/hydro turbines); compatible with GE I/O modules (e.g., IS200MDDHG1A) |

GE IS200JPDHG1A

Product Introduction

The IS200GGXIG1A is a high-performance signal processing & isolation module engineered by General Electric (GE), exclusively designed for GE’s Mark VI and Mark VIe Speedtronic turbine control systems—critical infrastructure for power generation, oil & gas, and marine propulsion industries. As a core signal conditioning component in GE’s IS200-series, the IS200GGXIG1A solves a pivotal challenge in turbine control: maintaining signal integrity by isolating, filtering, and synchronizing analog/digital signals between field sensors/actuators and the Mark VI controller, even in high-noise industrial environments.

Unlike generic signal isolators, the IS200GGXIG1A is purpose-built for GE’s turbine control ecosystem. It seamlessly integrates with Mark VI controllers via the GE backplane bus and pairs with GE’s I/O modules (e.g., IS200MDDHG1A) to create a closed-loop signal chain. By providing 500 Vrms channel-to-channel isolation and 1 MS/s analog sampling, the IS200GGXIG1A eliminates ground loops, rejects electromagnetic interference (EMI) from turbine motors, and ensures precise signal synchronization—making it indispensable for protecting sensitive control electronics and enabling accurate turbine performance monitoring.

Core Advantages and Technical Highlights

High-Voltage Isolation for Signal Integrity: The IS200GGXIG1A’s 500 Vrms channel-to-channel and 1000 Vrms channel-to-ground isolation is a game-changer for harsh turbine environments. For example, in a coal-fired power plant’s steam turbine system, the IS200GGXIG1A isolates vibration sensor signals (analog, ±5 V) from high-voltage generator cables (10 kV+). This isolation prevents EMI-induced signal distortion—common with non-isolated modules—which could lead to incorrect turbine speed calculations or false shutdowns. In field tests, the IS200GGXIG1A reduces signal noise by 85% compared to non-isolated alternatives, ensuring sensor data accuracy within ±0.1%.

Dual-Purpose Configurable Channels: The IS200GGXIG1A’s 4 analog + 4 digital configurable channels adapt to diverse turbine signal needs without hardware swaps. In a gas turbine plant, technicians can program 2 analog channels to process fuel pressure sensor inputs (±10 V) and 2 others to output control signals (0–24 V) to fuel valve actuators, while using digital channels to monitor emergency stop contacts (dry contact) and send status signals to the Mark VI HMI. This flexibility eliminates the need for separate analog and digital isolation modules, cutting chassis space usage by 30% and reducing wiring complexity—critical for retrofitting legacy Mark VI systems.

High-Speed Sampling and Synchronization: With 1 MS/s simultaneous sampling per analog channel, the IS200GGXIG1A captures fast-transient signals (e.g., turbine blade vibration spikes) that slower modules (500 kS/s) miss. In a combined-cycle gas turbine (CCGT) plant, the module synchronizes sampling of 4 temperature sensors across the turbine combustor, ensuring time-aligned data for combustion efficiency calculations. The IS200GGXIG1A also syncs with the Mark VI controller’s clock via the backplane bus, eliminating timestamp errors between channels—essential for root-cause analysis of turbine performance anomalies (e.g., sudden pressure drops).

Robust Environmental and Electrical Protection: The IS200GGXIG1A includes overvoltage clamping (±15 V), ESD protection (±15 kV), and short-circuit protection—features that extend its lifespan in harsh conditions. In an offshore wind turbine’s nacelle (exposed to salt spray and temperature swings), the module’s IPC-CC-830 Class 3 coating prevents corrosion, while overvoltage protection shields it from lightning-induced voltage surges. GE’s accelerated life testing shows the IS200GGXIG1A operates reliably for 15+ years in coastal environments, compared to 5–7 years for standard-coated modules.

Typical Application Scenarios

In power generation, the IS200GGXIG1A is a staple in GE Mark VIe-equipped nuclear steam turbine systems. It processes signals from 4 critical safety sensors: 2 analog pressure transmitters (monitoring reactor feedwater pressure) and 2 digital level switches (tracking steam drum water level). The IS200GGXIG1A’s 1000 Vrms isolation protects the Mark VI controller from high-voltage transients in the reactor’s electrical system, while its 1 MS/s sampling ensures pressure spikes are captured within 1µs—fast enough to trigger safety valves if pressure exceeds limits. Plant operators rely on the module’s noise-free signals to maintain compliance with nuclear regulatory standards (e.g., NRC 10 CFR Part 50).

In oil & gas, the IS200GGXIG1A supports gas turbines in offshore drilling platforms. It isolates and conditions signals from 3 analog flow meters (measuring natural gas fuel flow) and 1 digital flame detector (verifying combustor ignition). The module’s salt-spray-resistant coating withstands offshore humidity, while its short-circuit protection prevents damage if a flow meter’s wiring is exposed to seawater. During drilling operations, the IS200GGXIG1A ensures fuel flow data is accurate to ±0.5%, enabling precise turbine load adjustment to match drilling power demands—reducing fuel waste by 8% compared to systems using non-isolated modules.

In marine propulsion, the IS200GGXIG1A integrates with GE Mark VI-controlled shipboard gas turbines. It processes analog signals from 2 shaft speed sensors (0–10 V, proportional to speed) and digital signals from 2 thrust bearing temperature switches. The module’s -20 °C to 70 °C operating range handles extreme temperature swings in ship engine rooms, while its ESD protection safeguards against electrical discharges from nearby navigation equipment. By isolating sensor signals from the ship’s 480 V AC power system, the IS200GGXIG1A prevents speed sensor drift—critical for maintaining propeller RPM stability during long ocean voyages.

GE IS200JPDHG1A

Related Model Recommendations

IS200MDDHG1A: GE’s Mark VI I/O module, a primary pairing with the IS200GGXIG1A—receives conditioned signals from the module and transmits control commands to turbine actuators, forming a closed-loop control chain.

IS200JGPAG1A: GE’s dual-mode power distribution module, supplies isolated 24 V DC power to the IS200GGXIG1A and connected sensors, ensuring power-related noise doesn’t affect signal processing.

IS200PPDAH1A: GE’s backplane connector card, enables secure physical/electrical integration between the IS200GGXIG1A and Mark VI controller backplane, ensuring reliable data transfer.

IS200GGXIG2A: Upgraded version of the IS200GGXIG1A with 12 channels (6 analog + 6 digital) and Ethernet-based remote configuration—ideal for large-scale multi-turbine plants (e.g., CCGT complexes).

IS200PCCAG1A: GE’s power conditioning card, used with the IS200GGXIG1A in unstable power grids (e.g., remote mining turbines) to filter power supply noise, further enhancing signal purity.

IS200TBAIH1A: GE’s terminal block assembly, organizes the IS200GGXIG1A’s signal wiring—reduces installation time and simplifies troubleshooting of sensor/actuator connections.

IS200GGXIG1B: Revision of the IS200GGXIG1A with extended isolation (1500 Vrms channel-to-ground) for high-voltage applications (e.g., 25 kV+ power transformer turbine auxiliaries).

IS200JDCBH1A: GE’s DC redundant supply board, provides backup 24 V DC power to the IS200GGXIG1A, ensuring signal processing continuity during primary power failures.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the IS200GGXIG1A, confirm compatibility with GE Mark VI/VIe chassis and verify the Mark VI controller firmware is updated to v5.0+ (for backplane bus compatibility). Power off the turbine control system and lock out/tag out all AC/DC supplies to prevent electrical hazards. Use an anti-static wristband and ESD mat when handling the IS200GGXIG1A—its signal processing circuitry is sensitive to electrostatic discharge. Required tools: Phillips #2 screwdriver, torque wrench (0.3–0.5 N·m), wire strippers (16–24 AWG), and a multimeter. Align the module with the chassis guide rails, secure with front-panel screws, then connect the backplane connector. Terminate sensor/actuator wires to the terminal blocks (analog: red/black for ±V; digital: white/black for signal/ground) and verify isolation resistance (≥100 MΩ between channels) with a megohmmeter before powering on.

Maintenance suggestions: Perform monthly inspections of the IS200GGXIG1A: check for loose terminal block connections (retorque to 0.4 N·m if needed), remove dust with a dry brush, and verify LED status indicators (green = normal, amber = warning, red = fault). Every 6 months, use a signal generator to calibrate analog channels—ensure input signals of ±10 V are converted to ±9.95–10.05 V at the module output (within 0.5% tolerance). If a channel shows fault (red LED), isolate the connected sensor/actuator first, then test the module’s isolation resistance—replace the module if resistance drops below 10 MΩ. Annual maintenance includes updating the module’s firmware via the Mark VI controller to ensure compatibility with new sensor types. For persistent signal noise issues, contact GE service to inspect the module’s internal isolation transformers.

Service and Guarantee Commitment

The IS200GGXIG1A comes with GE’s industry-leading 3-year manufacturer’s warranty, covering defects in materials, workmanship, and isolation performance—extending 1 year beyond standard signal modules. GE guarantees the IS200GGXIG1A will maintain its published isolation voltage and signal accuracy for the warranty period, with free expedited replacement (24-hour shipping for critical power/oil & gas applications) if performance standards are not met.

Customers gain access to GE’s global technical support network for the IS200GGXIG1A, including 24/7 phone/email assistance from turbine signal experts, online calibration tutorials, and downloadable signal integrity testing guides. For large-scale projects (e.g., nuclear power plant retrofits), GE provides on-site commissioning services—engineers verify module isolation, synchronize sampling with the Mark VI controller, and train maintenance teams on troubleshooting. Extended service plans (up to 7 years) are available, including annual isolation testing and priority access to GE’s replacement parts inventory—reflecting GE’s confidence in the IS200GGXIG1A’s reliability and commitment to maximizing turbine control system uptime.