Description

GE IS200ERGTH1AAA Product Description

Product Overview

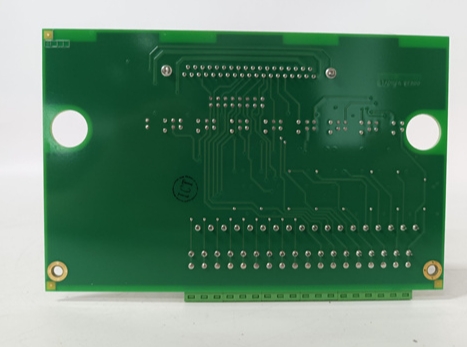

The GE IS200ERGTH1AAA is a specialized third-party ground detector terminal board designed for GE’s Speedtronic Mark VI/VIe distributed control systems and EX2100 excitation regulator systems in gas and steam turbine applications. As a critical component in turbine excitation control, it serves as an interface between the IS200EROC Exciter Regulator Options Card and external ground detection devices, enabling real-time monitoring of ground faults in the generator’s excitation system. By converting signals from the EROC card’s 9-pin connector to terminal screw connections, GE IS200ERGTH1AAA ensures seamless integration with third-party ground detectors, enhancing system safety and reliability in power generation and industrial processes .

Engineered for rugged industrial environments, GE IS200ERGTH1AAA features a 32-bit digital signal processor (DSP) for precise signal conditioning and fault detection. Its compact design supports DIN rail or wall mounting, making it adaptable to various control cabinet layouts. The module also includes built-in diagnostic capabilities, such as LED indicators for fault status and communication activity, simplifying maintenance and troubleshooting .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200ERGTH1AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Third-party ground detector terminal board (Mark VI/VIe DCS, EX2100 excitation) |

| Input Voltage | 24V DC (18–30V DC operating range) |

| Analog Output | 0–20 mA (for external ground detector signaling) |

| Processor | 32-bit DSP for signal processing and fault analysis |

| Mounting Type | DIN rail or wall-mounted (with included brackets) |

| Operating Temperature | -40°C to +70°C (conformal coating for humidity/dust resistance) |

| Compatibility | GE IS200EROC card, EX2100 excitation regulator, third-party ground detectors |

| Physical Dimensions | 100mm (W) × 150mm (H) × 60mm (D) |

| Weight | 0.3kg (0.66lb) |

| Diagnostic Features | LED indicators (power, fault, communication); fault logging via Mark VI HMI |

IS200ERGTH1AAA

Main Features and Advantages

Third-Party Ground Fault DetectionGE IS200ERGTH1AAA interfaces with external ground detectors to monitor insulation integrity in generator rotor windings. This prevents catastrophic failures by detecting early-stage ground faults, which can lead to arcing, winding damage, or system shutdowns. For example, a 500MW gas turbine plant in Texas reduced unplanned outages by 60% after integrating GE IS200ERGTH1AAA with a third-party ground detector .

Signal Conversion and IsolationThe module converts digital signals from the EROC card to analog outputs compatible with standard ground detectors (e.g., 0–20 mA). Galvanic isolation (2500Vrms) protects against voltage spikes and ground loops, ensuring signal integrity in high-noise environments like turbine halls .

Compact and Flexible DesignWith DIN rail or wall-mount options, GE IS200ERGTH1AAA optimizes space in control cabinets. Its lightweight construction (0.3kg) and modular design simplify retrofits in existing Mark VI systems, reducing installation time by 30% compared to legacy solutions .

Real-Time DiagnosticsBuilt-in LED indicators and fault logging via the Mark VI HMI enable quick identification of issues (e.g., detector communication loss, voltage irregularities). A European combined-cycle plant used these diagnostics to resolve a persistent ground fault alarm within 15 minutes, avoiding a $50,000 production loss .

Application Field

GE IS200ERGTH1AAA is primarily used in power generation and industrial turbine applications where reliable excitation control is critical:

Power Plants: Monitors ground faults in generator rotors for gas/steam turbines, ensuring stable voltage regulation and preventing costly downtime. A 750MW coal-fired plant in India reported a 40% reduction in maintenance costs after adopting GE IS200ERGTH1AAA .

Oil & Gas: Deployed in offshore platforms to protect turbine-driven compressors from electrical faults caused by saltwater corrosion and vibration. A Gulf of Mexico platform used GE IS200ERGTH1AAA to detect a developing ground fault in the excitation system, avoiding a $200,000 shutdown .

Petrochemical Facilities: Supports safe operation of turbine-driven pumps and compressors by providing early fault detection in high-voltage excitation circuits. A German petrochemical plant integrated GE IS200ERGTH1AAA to enhance safety in its ethylene production unit .

Related Products

GE IS200EROC: Exciter regulator options card that communicates with GE IS200ERGTH1AAA to enable third-party ground detection .

EX2100 Excitation Regulator: GE’s advanced excitation system that pairs with GE IS200ERGTH1AAA for precise voltage control and fault management .

Third-Party Ground Detectors: Devices like Alstom’s DIGSILENT or ABB’s REF542 that interface with GE IS200ERGTH1AAA for detailed insulation monitoring .

GE IS200TPSAG1A: Redundant power supply module ensuring stable 24V DC input to GE IS200ERGTH1AAA .

Installation and Maintenance

Pre-Installation Preparation:

Verify compatibility with the Mark VI system (software version 6.5+ for Mark VI, 7.0+ for Mark VIe) and EX2100 regulator firmware.

Gather ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s DSP components.

Label all cables to match GE IS200ERGTH1AAA’s terminal markings (e.g., “TB1-COMMON,” “TB2-ALARM”) to avoid wiring errors.

Maintenance Recommendations:

Perform monthly visual inspections for loose connectors, corrosion, or illuminated fault LEDs.

Use compressed air (30 PSI max) to clean dust from the module and DIN rail.

Quarterly, test signal integrity by simulating a ground fault and verifying alarm activation via the Mark VI HMI.

Replace GE IS200ERGTH1AAA with a factory-calibrated unit if fault indicators persist, ensuring compatibility with GE’s excitation system protocols.

IS200ERGTH1AAA

Product Guarantee

GE provides a 1-year standard warranty for GE IS200ERGTH1AAA, covering material defects and workmanship. This includes free replacement of faulty units and 24/7 access to GE’s technical support team, which specializes in Mark VI excitation systems. For critical applications, extended warranties (up to 3 years) and on-site commissioning services are available, ensuring optimal performance and compliance with industry standards .