Description

Key Technical Specifications

| Parameter | Details |

|---|---|

| Manufacturer | ICS Triplex (affiliated to Rockwell Automation) |

| Core Architecture | Triple Modular Redundancy (TMR), with three independent processing channels for mutual monitoring to isolate faulty channels automatically |

| I/O Capacity | Can accommodate up to 16 Trusted I/O modules, providing a total of 256 I/O points |

| Power Supply | 24VDC, which is compatible with the common power supply standard of industrial control equipment |

| Programming Languages | Supports ladder logic, function block diagrams and structured text, adapting to various control strategy design requirements |

| Communication Interfaces | Equipped with Ethernet (TCP/IP, UDP), RS – 232, RS – 485, Profibus, Foundation Fieldbus and Modbus, enabling seamless integration with other controllers and field devices |

| Environmental Adaptability | Operating temperature ranges from -40°C to 70°C, which can cope with the harsh temperature environment of most industrial sites |

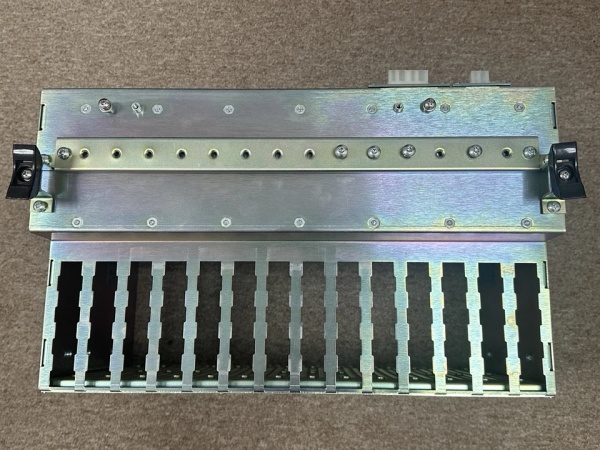

| Physical Specifications | Dimensions are 210mm×160mm×85mm; weight is about 2kg; adopts DIN rail mounting method |

| Maintenance Performance | Supports hot – swapping of modules, which can reduce system downtime during maintenance |

ICS TRIPLEX T8300

Field Application & Problem Solved

In industries such as oil and gas, petrochemicals, and power generation, as the production scale expands, the original control system often has insufficient I/O capacity, which makes it impossible to connect newly added sensors, actuators and other equipment. Meanwhile, once the control system breaks down due to a single point of failure during the production process, it may trigger serious safety accidents such as leaks and explosions.

The T8300 effectively solves these problems. In large petrochemical plants, it is matched with the Trusted safety controller to expand the I/O capacity. It connects a large number of sensors that monitor the temperature and pressure of pipelines and the actuators of emergency valves, ensuring that the system can collect and respond to field signals comprehensively. In coal – fired power plants, it is applied in the boiler control system. Its TMR architecture ensures that even if one processing channel fails, the system can still stably control the fuel supply and air intake of the boiler, avoiding boiler shutdown caused by system failure. In the water treatment industry, it expands the I/O ports of the sewage treatment control system, connects multiple water quality detection sensors and water pump operation control terminals, and ensures the continuous and stable operation of the sewage treatment process.

Installation & Maintenance Pitfalls (Expert Tips)

- Improper Matching of I/O Modules: When installing I/O modules, if non – Trusted series modules are used, it will lead to incompatibility problems such as communication failure between the module and the chassis. It is necessary to confirm that the installed I/O modules are all Trusted series products, and check whether the module insertion is in place after installation to prevent poor contact.

- Neglecting Installation Stability: Although it supports DIN rail installation, if the fixing force is insufficient during installation, the chassis may loosen due to the vibration of industrial equipment. After installation, it is necessary to manually check the firmness of the chassis, and install shock pads for the chassis in high – vibration places such as machine workshops.

- Rough Operation During Module Replacement: When performing hot – swapping of modules, if the module is pulled out or inserted too roughly, the pins in the chassis may be damaged. It is necessary to operate in accordance with the equipment manual, and confirm that there is no critical operation being executed by the system before replacement to avoid system signal disorder.

- Ignoring the Protection of the Hinged Front Cover: The hinged front cover is designed to protect the internal I/O modules. Some operators do not cover it after maintenance. In dusty industrial environments, dust will accumulate on the module connectors and affect the signal transmission. It is necessary to close the front cover in time after daily inspection and maintenance.

ICS TRIPLEX T8300

Technical Deep Dive & Overview

The core value of the T8300 lies in its ability to expand the I/O capacity of the Trusted safety control system while maintaining high safety and reliability. Its TMR architecture is the key to ensuring fault tolerance. When a single processing channel breaks down, the other two normal channels can take over the work immediately, and the whole process is seamless, without affecting the normal operation of the industrial production process.

Compared with ordinary expander chassis, it has strong compatibility. Its rich communication interfaces allow it to be integrated with different types of field devices and upper – level controllers without additional protocol conversion modules, which simplifies the system structure. Moreover, its scalable design is very in line with the needs of enterprise development. When the production line is expanded, enterprises only need to add I/O modules on the T8300 chassis instead of replacing the entire controller, which greatly reduces the transformation cost.

In addition, the real – time fault monitoring function of the T8300 can detect potential faults of the module in time. Combined with the convenient maintenance design such as the hinged front cover, maintenance personnel can quickly locate and solve problems, reducing the time of system failure and improving the overall operation efficiency of the industrial production line. It is an important supporting component to ensure the stable operation of the Trusted series safety control system in large – scale industrial scenarios.