Description

Key Technical Specifications

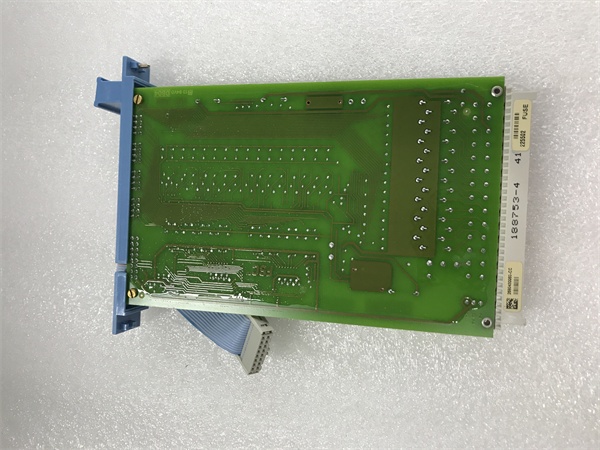

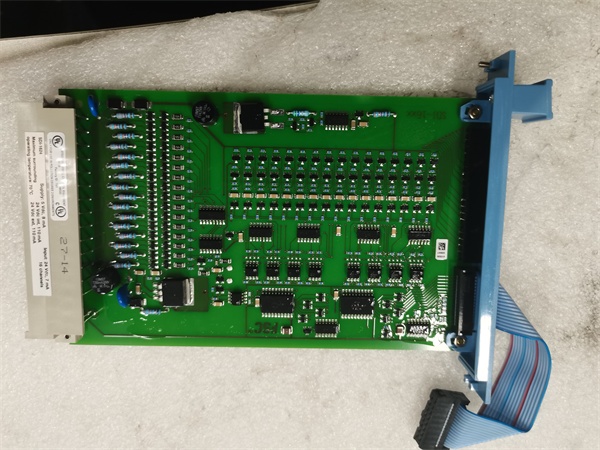

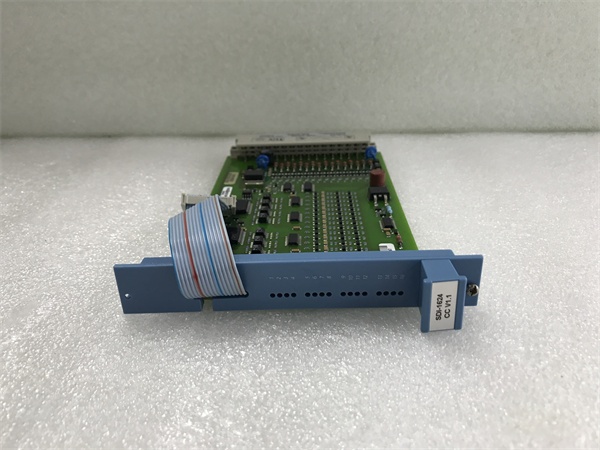

- Model Number: SDI-1624 (FC-SDI-1624)

- Manufacturer: Honeywell Industrial Automation

- Input Channels: 16 independent 24VDC digital inputs

- Input Voltage Range: 18–32VDC (operational); High = >15VDC, Low = <9VDC

- Input Current: 7mA @ 24VDC (nominal); <2mA for low-state detection

- Power Requirements: 5VDC (logic, 8mA) + 24VDC (field, 110mA)

- Input Delay: 10ms (typical; no user adjustment possible)

- Isolation: 2500V AC (field to logic; 1 minute test)

- Environmental Rating: Operating Temp: -20°C to +60°C; Storage Temp: -40°C to +85°C

- Protection Level: IP65 (front face); conformal coating for humidity/corrosion resistance

- Short-Circuit Protection: 450mA max current limit per channel; self-resetting

- Certifications: TÜV, UL, CSA, CE; SIL 2/3 capable when used in SIS architectures

Honeywell SDI-1624

Field Application & Problem Solved

In refineries, power plants, and chemical processing facilities, the biggest headache with discrete input modules is false trips and unplanned downtime caused by signal noise or channel failures. Legacy input modules often lack robust isolation, leading to cross-talk between channels when exposed to high electromagnetic interference (EMI) from pumps, motors, and variable frequency drives (VFDs). This is where the SDI-1624 shines—it’s built to handle the harsh EMI environments that fry cheaper modules.

You’ll find this module in safety loops: monitoring emergency shutdown (ESD) valve position, flame detector status, and pressure switch trips on hydrocracking units or boiler feedwater systems. Its core value is reliability— the solid-state design eliminates moving parts that wear out in vibration-heavy areas like turbine halls. Unlike relay-based inputs, it doesn’t suffer from contact bounce, which means no false alarms from limit switches on conveyor belts or valve actuators.

Another critical problem it solves is short-circuit resilience. In muddy or wet environments (common in paper mills or offshore platforms), field wiring often gets damaged, leading to ground faults. The SDI-1624’s 450mA current limit prevents module burnout, so a single shorted channel doesn’t take down the entire module. This saves hours of troubleshooting—you can isolate the faulted channel via the controller’s diagnostic screen and keep the rest of the loop running.

Installation & Maintenance Pitfalls (Expert Tips)

Field Wiring Polarity is Non-Negotiable

Rookies often wire this module without checking polarity, assuming it’s “just a digital input.” Wrong—reverse polarity on the 24VDC field side will cause the channel to show a permanent low state, but won’t damage the module (thanks to the protection circuit). The problem? You’ll waste hours chasing a “failed” pressure switch when the issue is just flipped wires. Always match the module’s “+” terminal to the switch’s positive output—mark wires clearly for future maintenance.

Don’t Skip Shield Grounding

The module’s isolation is great, but improper shield grounding on field cables will introduce EMI noise, leading to intermittent “flickering” input states. Run the cable shield to a single point ground at the module end—never ground both ends (this creates a ground loop). I’ve seen plants replace entire modules because they ignored this rule, only to find the fix was a $5 grounding clamp.

Diagnostic Data is Your Best Friend

The SDI-1624 reports channel health to the Safety Manager controller, but most techs never check it. The diagnostic screen shows overcurrent events, low voltage, and open circuits—use it. During a turnaround, pull the diagnostic logs for the last 6 months; this will tell you which channels are flaky (likely due to aging wiring) before they cause a shutdown. Don’t wait for a fault to act—proactively replace suspect wiring.

Avoid Over-Tightening Terminal Screws

The terminal blocks are plastic, and over-tightening (with a power drill, of all things) strips the threads or cracks the housing. Use a manual torque screwdriver—2 in-lbs is all you need. A stripped terminal means you’ll have to bypass the channel or replace the module, which is a nightmare during a production run.

Honeywell SDI-1624

Technical Deep Dive & Overview

The SDI-1624 is a passive safe input module— it doesn’t amplify signals; it simply conditions and isolates them for the Safety Manager controller. Each channel has a dedicated current-limiting resistor and optocoupler, which provides the 2500V isolation between the field (hazardous area) and logic (safe area) sides. The optocoupler converts the analog voltage signal into a digital logic signal (0/1) that the controller can process.

Unlike intelligent modules, it has no on-board processor—all signal processing happens in the controller. This is a strength in safety systems: fewer components mean fewer failure points. The conformal coating is a critical design feature— it’s not just for corrosion resistance; it prevents moisture from bridging between terminals in high-humidity environments, a common cause of channel cross-talk.

When integrated into a SIL 3 safety loop, the module relies on the controller’s voting logic (1oo2, 2oo3) for fault tolerance. Its short-circuit protection is passive— it limits current without needing software intervention, which is essential for fail-safe operation. In the field, this translates to a module that runs for years without maintenance, as long as you follow the wiring and grounding rules.