Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FTA-T-14 |

| Manufacturer | Honeywell |

| Product category | Safety digital I/O module (multi-functional) |

| Input voltage | 24 VDC or 120 VAC (digital input mode) |

| Output voltage | 36 VAC/50 VDC (Overvoltage Category III), 125 VAC/150 VDC (Overvoltage Category II) |

| Maximum output current | 2 A per channel |

| Channel configuration | Configurable as 14 safety digital outputs or 4 digital inputs |

| Operating temperature | -20°C to +65°C |

| Storage temperature | -40°C to +105°C |

| Dimensions | 94 mm x 95.3 mm x 57.2 mm |

| Weight | 0.25 kg |

| Certifications | CE, TÜV, UL, CSA |

| Mounting type | DIN rail mounting |

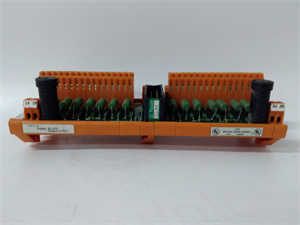

Honeywell FTA-T-14

Product introduction

The Honeywell FTA-T-14 is a versatile safety digital I/O module designed for critical industrial automation applications requiring reliable signal processing and control. As part of Honeywell’s safety automation portfolio, this multi-functional module bridges field devices and control systems, offering flexible configuration as either 14 safety digital outputs or 4 digital inputs to meet diverse application needs.

Honeywell FTA-T-14 excels in environments where safety and reliability are paramount, providing fail-safe operation that ensures outputs transition to a safe state during system anomalies. Its robust design allows seamless integration with major industrial control systems, including Allen-Bradley ControlLogix PLCs, making it a valuable component in both new installations and system upgrades. Whether deployed in process industries or manufacturing facilities, Honeywell FTA-T-14 delivers consistent performance that enhances overall system integrity.

Core advantages and technical highlights

Safety integrity: FTA-T-14 incorporates advanced fail-safe mechanisms that automatically transition outputs to a predefined safe state during internal faults or communication failures. This critical feature minimizes risk in hazardous environments, ensuring compliance with safety standards in industries such as chemical processing and oil & gas production. The module’s design includes comprehensive self-diagnostics that continuously monitor operational status, providing early warning of potential issues before they affect system performance.

Versatile configuration: Unlike fixed-function modules, FTA-T-14 offers flexible channel configuration as either 14 safety digital outputs or 4 digital inputs, adapting to changing application requirements without hardware replacement. This versatility reduces inventory costs and simplifies system design, allowing engineers to standardize on a single module type for multiple I/O needs. The module’s ability to handle both 24 VDC and 120 VAC inputs further enhances its adaptability across diverse industrial environments.

Robust industrial design: Built to withstand harsh operating conditions, FTA-T-14 operates reliably in temperatures ranging from -20°C to +65°C, making it suitable for both indoor and outdoor installations. Its rugged construction resists vibration, electromagnetic interference, and transient voltage spikes commonly found in industrial settings. The module’s compact form factor (94 mm x 95.3 mm x 57.2 mm) saves valuable panel space while supporting high-density I/O configurations.

Seamless system integration: FTA-T-14 features industry-standard interfaces that ensure compatibility with major PLC and DCS platforms, including Honeywell’s own control systems and third-party solutions like Allen-Bradley ControlLogix. This interoperability simplifies integration into existing infrastructures, reducing implementation time and ensuring consistent communication across the automation system. The module’s standardized wiring terminals accommodate 0.25 cm² (AWG 14) cables, facilitating secure and reliable connections.

Typical application scenarios

In chemical processing plants, FTA-T-14 plays a critical role in emergency shutdown systems, where its safety outputs control isolation valves and emergency depressurization equipment. During abnormal process conditions, the module’s rapid response ensures immediate activation of safety measures, preventing hazardous material releases. Its ability to operate in extreme temperatures makes it ideal for installation near reactors and distillation columns where ambient conditions can fluctuate significantly.

Manufacturing facilities utilize FTA-T-14 to monitor and control machinery safety interlocks, with its digital inputs receiving signals from emergency stop buttons and guard door sensors. The module’s fail-safe design ensures production lines halt safely during equipment malfunctions or operator intervention, protecting personnel and preventing equipment damage. Its compact size allows installation in control cabinets with limited space, common in automotive and packaging production cells.

Oil and gas production platforms rely on FTA-T-14 for offshore safety systems, where it manages fire suppression controls and gas detection alarms. The module’s robust construction withstands the harsh marine environment, including salt spray and vibration, ensuring reliable operation in remote locations where maintenance access is limited. Its versatile configuration allows system designers to optimize I/O layout based on specific platform requirements, enhancing overall safety system efficiency.

Honeywell FTA-T-14

Related model recommendations

Honeywell FTA-T-8: A compact version with 8 output channels, ideal for smaller safety loops requiring fewer I/O points, offering the same safety features as FTA-T-14 in a reduced form factor.

Honeywell FTA-AI-16: Analog input module that complements FTA-T-14 by providing 16 channels for monitoring process variables like pressure and temperature in safety systems.

Allen-Bradley 1756-Safety IO: Safety-rated I/O module compatible with ControlLogix systems, serving as an alternative when standardized on Rockwell Automation platforms alongside FTA-T-14.

Honeywell SIS-IO-24: High-density safety I/O module that extends system capabilities when paired with FTA-T-14 in large-scale safety instrumented systems.

Siemens 3RK1304: Safety relay module that works with FTA-T-14 to provide additional safety interlock functionality in mixed-vendor automation environments.

Honeywell FTA-DO-32: Expanded 32-channel digital output module that can be used alongside FTA-T-14 when higher I/O density is required in safety applications.

Installation, commissioning and maintenance instructions

Installation preparation: Mount FTA-T-14 on a 35 mm DIN rail in a clean, dry enclosure with adequate ventilation to maintain operating temperatures within the -20°C to +65°C range. Ensure proper grounding according to local electrical codes to prevent noise interference. Use 0.25 cm² (AWG 14) cables with 0.7 cm stripped ends for terminal connections, tightening screws to 0.5 Nm torque. Verify that the power supply matches the module’s voltage requirements (24 VDC or 120 VAC) before connection.

Commissioning and maintenance: After installation, configure FTA-T-14 using compatible programming software to set channel modes (input/output) and safety parameters according to system requirements. Perform functional tests by simulating input signals and verifying corresponding output responses. For ongoing maintenance, inspect the module quarterly for loose connections, signs of overheating, or corrosion. Clean terminals with a dry cloth if dust accumulation is observed. When replacing components, use only Honeywell-approved spare parts to maintain safety integrity and performance specifications.

Service and guarantee commitment

Honeywell FTA-T-14 is backed by a 12-month warranty covering manufacturing defects and ensuring compliance with published performance specifications. Honeywell’s global technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, with response times guaranteed within 4 hours for critical issues.

Customers receive access to comprehensive technical documentation, including installation guides and configuration manuals, to facilitate proper implementation. Extended warranty options are available, offering up to 3 years of coverage with preventive maintenance services. Honeywell maintains regional stock of FTA-T-14 modules to ensure prompt replacement when needed, minimizing system downtime. All repairs use genuine components, ensuring restored performance meets original specifications and safety standards.