Description

Detailed parameter table

| Parameter name | Parameter value |

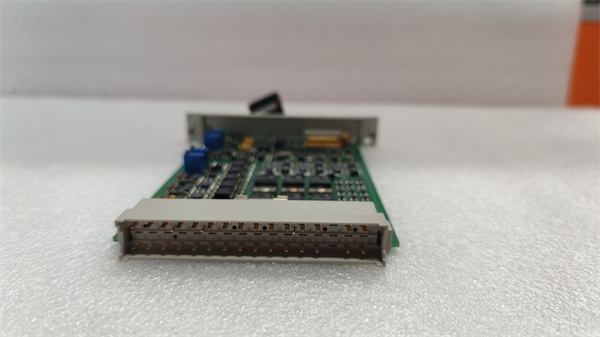

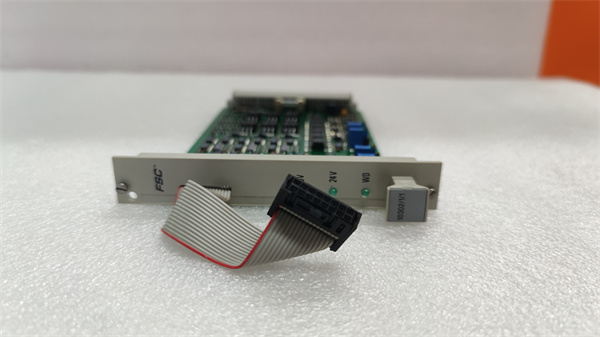

| Product model | 10302/1/1 |

| Manufacturer | Honeywell |

| Product category | Watchdog repeater module |

| Power monitoring | 5VDC and 24VDC power supplies for I/O modules |

| Power requirements | 5VDC: 35mA (no wdrout output current); 24VDC: 25mA |

| Input current | Wdg 1 + wdg 2: 0.1mA |

| Maximum output current | Wdr out: 900mA |

| Space requirements | 4TE, 3HE (equivalent to 4HP, 3U) |

| Installation position | I/O rack (positions 1 to 18) |

| Hot-swap support | Yes (with potential central section shutdown during replacement) |

| Certifications | CE, TÜV, UL |

| Operating temperature range | -40°C to +70°C |

| Humidity tolerance | 0% – 95% non-condensing |

Honeywell 10302/1/1

Product introduction

The Honeywell 10302/1/1 is a critical watchdog repeater module designed to safeguard the integrity of industrial automation systems by continuously monitoring power supplies. As a key component in Honeywell’s industrial control ecosystem, it focuses on ensuring the stable operation of 5VDC and 24VDC power sources that feed I/O modules, which are essential for data acquisition and control in complex automation setups.

At its core, the Honeywell 10302/1/1 provides a dedicated watchdog output that connects to the watchdog input of monitored output modules, creating a closed-loop monitoring system. This functionality is particularly vital in configurations with multiple power supplies, specific power types, or mixed redundant and non-redundant I/O components, where even brief power irregularities can disrupt critical processes. By acting as a vigilant power sentinel, the Honeywell 10302/1/1 helps prevent system failures and minimizes downtime in industrial environments.

Core advantages and technical highlights

Comprehensive power monitoring: The Honeywell 10302/1/1 stands out for its ability to simultaneously monitor both 5VDC and 24VDC power supplies, covering the primary voltage requirements of most industrial I/O modules. This dual monitoring capability ensures that no critical power source is left unmonitored, providing a holistic approach to system power integrity. Unlike single-voltage monitors, it eliminates blind spots in power supervision, making it ideal for complex systems with varied power needs.

Robust performance metrics: With a maximum output current of 900mA for its watchdog signal, the Honeywell 10302/1/1 delivers a strong, reliable trigger signal that can activate protective mechanisms even in systems with higher load requirements. Its low input current (0.1mA for watchdog inputs) ensures minimal power draw, preventing interference with the very power supplies it monitors. This balance of strong output and low input makes it both effective and efficient.

Flexible integration: The Honeywell 10302/1/1 is designed for seamless integration into existing I/O racks, fitting into positions 1 to 18 without requiring extensive reconfiguration. Its support for hot-swapping adds a layer of operational convenience, allowing for maintenance or replacement without fully shutting down the entire system—though users should note the potential for temporary central section shutdown during this process. This flexibility makes it suitable for both new installations and retrofits in aging automation systems.

Typical application scenarios

In chemical processing plants, where precise control of valves, pumps, and sensors is critical for safety and product quality, the Honeywell 10302/1/1 plays a vital role. These facilities often use complex I/O configurations with redundant and non-redundant components, making power stability paramount. The Honeywell 10302/1/1 ensures that the power feeding these I/O modules remains within acceptable parameters, preventing unexpected shutdowns of mixing processes or temperature control systems that could lead to product batch failures or safety hazards.

Within oil and gas production facilities, particularly in upstream drilling operations, the Honeywell 10302/1/1 provides essential power monitoring for I/O modules controlling critical equipment like blowout preventers and pressure sensors. In these remote, harsh environments, power fluctuations are more common, and system failures can have severe consequences. By continuously monitoring power supplies and triggering appropriate responses via its watchdog output, the Honeywell 10302/1/1 helps maintain uninterrupted operation of drilling control systems, protecting both equipment and personnel.

In large-scale manufacturing facilities, such as automotive assembly lines, the Honeywell 10302/1/1 ensures the reliability of I/O modules that control robotic arms, conveyor systems, and quality inspection sensors. These facilities operate on tight production schedules, and even brief disruptions can lead to significant downtime and lost productivity. The Honeywell 10302/1/1 acts as a safeguard, detecting power issues before they escalate into system failures and allowing maintenance teams to address problems proactively.

Honeywell 10302/1/1

Related model recommendations

Honeywell 10302/2/1: A variant with enhanced redundancy features, designed for systems requiring dual watchdog outputs. It serves as an upgraded option for high-availability setups.

Honeywell SDT-1624: A digital input module that works with the Honeywell 10302/1/1 to provide comprehensive input monitoring, with the watchdog module ensuring its power stability.

Honeywell SDO-0824: A digital output module that pairs with the Honeywell 10302/1/1, receiving watchdog signals to trigger protective actions during power anomalies.

Honeywell 51304653-100: A power supply module compatible with the Honeywell 10302/1/1, providing the 5VDC and 24VDC outputs that the watchdog module monitors.

Honeywell 900H08-0101: A redundant power system controller that integrates with the Honeywell 10302/1/1 to manage power 切换 in redundant configurations.

Honeywell FSC 1030: A safety controller that uses the Honeywell 10302/1/1 as part of its power monitoring subsystem, enhancing overall safety integrity.

Honeywell TDC 3000: A distributed control system where the Honeywell 10302/1/1 is commonly used to monitor power for I/O components in the system.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the Honeywell 10302/1/1, ensure the I/O rack is powered down and verify that the installation environment meets the module’s specifications—temperature between -40°C and +70°C, humidity between 0% and 95% non-condensing, and free from excessive vibration or corrosive substances. Gather necessary tools: a Phillips screwdriver for rack mounting, wire strippers for power connections, and a multimeter to verify voltage levels. Check that the rack position (1-18) is compatible and that the backplane connectors are clean and undamaged. Always wear electrostatic discharge (ESD) protection to prevent damage to sensitive components during handling.

Maintenance suggestions: For daily maintenance, visually inspect the Honeywell 10302/1/1 for loose connections, signs of overheating (discoloration), or physical damage. Use the system’s diagnostic software to check for watchdog trigger events, which can indicate underlying power issues. When troubleshooting, first verify power input levels with a multimeter to ensure they are within the 5VDC and 24VDC ranges. If replacement is needed, perform hot-swap only when necessary, and be prepared for a potential temporary shutdown of the central section. Store spare Honeywell 10302/1/1 modules in ESD-protected packaging in a dry environment to maintain their integrity.

Service and guarantee commitment

The Honeywell 10302/1/1 comes with a 12-month warranty from the date of purchase, covering manufacturing defects and ensuring that the module meets Honeywell’s strict performance standards. If a defect is identified within this period, Honeywell will repair or replace the module at no cost, ensuring minimal disruption to your operations.

Honeywell provides comprehensive technical support for the Honeywell 10302/1/1, including access to detailed installation manuals, troubleshooting guides, and online resources through its customer portal. Our team of industrial automation experts is available to assist with integration questions, commissioning support, and maintenance advice, ensuring that you get the most out of your module. We stand behind the reliability of the Honeywell 10302/1/1 and are committed to helping our customers maintain robust, efficient automation systems through responsive service and quality assurance.