Description

1. Product Overview

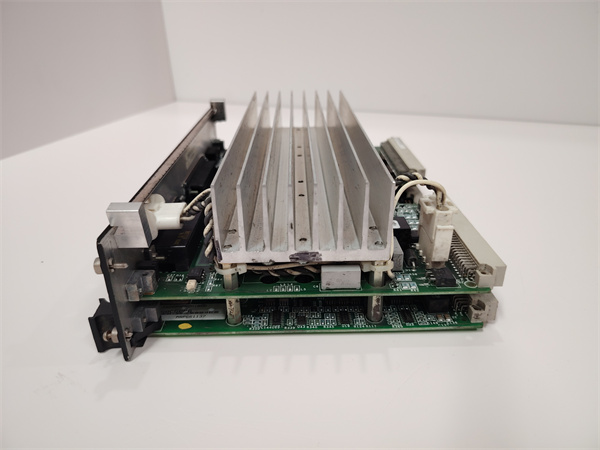

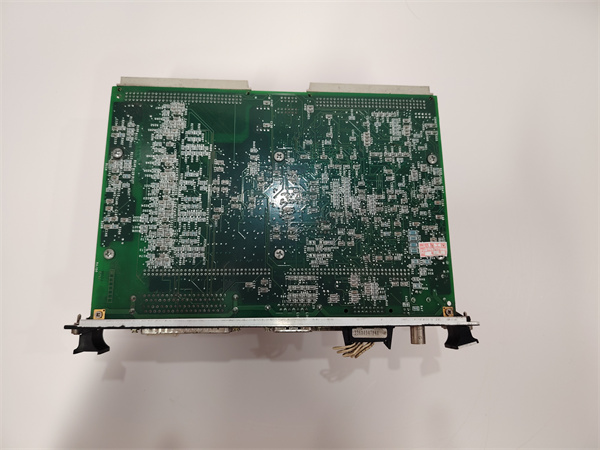

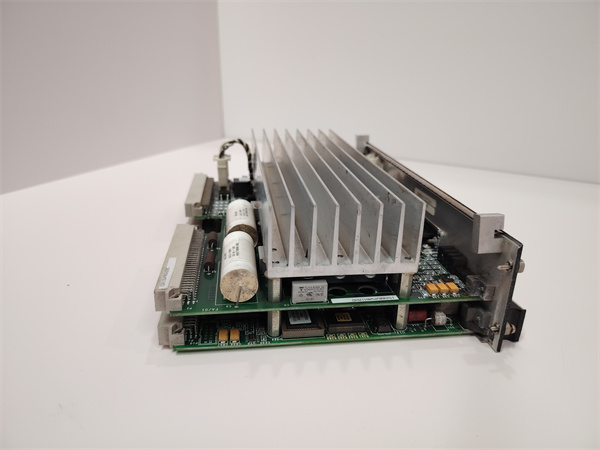

The GE VPROH2B IS215VPROH2BC is a high – performance industrial input/output (I/O) module, designed to be a crucial component in industrial control systems. As part of GE’s extensive range of industrial automation products, it is engineered to meet the demands of complex industrial environments, providing reliable data transfer and control capabilities between field devices and control systems. This module plays a pivotal role in ensuring seamless operation within industrial setups, where precision and stability are of utmost importance.

2. Technical Specifications

| Parameter Name | Parameter Value |

| Model | VPROH2B IS215VPROH2BC |

| I/O Configuration | Features a configurable mix of input and output channels. It typically includes digital inputs that can interface with sensors, switches, and other binary – state devices. These digital inputs are designed to accurately detect the on/off status of field devices, providing real – time information to the control system. On the output side, it has digital outputs capable of driving relays, solenoids, and other actuators. The number of input and output channels can vary, but it is designed to offer a versatile configuration to suit different industrial applications. |

| Signal Compatibility | Compatible with a wide range of industrial signal levels. For digital inputs, it can handle standard voltages such as 24V DC, which are commonly used in industrial sensors and switches. This ensures easy integration with existing field devices without the need for extensive signal conditioning. The digital outputs are designed to provide sufficient current to drive the connected actuators, typically in the range of a few hundred milliamperes, depending on the specific model. |

| Communication Protocols | Supports popular industrial communication protocols, such as Modbus. This allows for seamless integration with other components in the industrial network, including programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other I/O modules. Modbus enables reliable data transfer between devices, facilitating efficient control and monitoring of industrial processes. |

| Environmental Adaptability | Engineered to withstand harsh industrial environments. It has an extended temperature range, allowing it to operate effectively in extreme heat or cold conditions. Whether in a hot industrial furnace area or a cold outdoor mining site, the module can maintain stable performance. It is also highly resistant to electrical noise, which is prevalent in industrial settings with a large number of electrical equipment. This resistance ensures that the data transfer remains accurate and free from interference, even in electrically noisy environments. Additionally, it is designed to be resistant to vibration and shock, which are common in industrial plants with moving machinery. |

| Diagnostic Features | Equipped with comprehensive diagnostic capabilities. It can continuously monitor the status of its input and output channels, detecting any faults or abnormal conditions. In case of a channel failure or incorrect signal levels, the module can generate diagnostic messages. These messages can be used by maintenance personnel to quickly identify and troubleshoot problems, reducing downtime and minimizing the impact on industrial operations. |

| Mounting and Connectivity | Designed for easy installation. It typically has a compact form factor, which helps in saving space in control panels. The module can be mounted using standard DIN – rail mounting, which is a common method in industrial control systems. In terms of connectivity, it has clearly marked terminals for connecting field wires. These terminals are designed to provide a secure and reliable connection, ensuring that the signals are properly transmitted between the module and the field devices. |

VPROH2B IS215VPROH2BC

3. Core Advantages

Reliability in Harsh Conditions: The ability of the GE VPROH2B IS215VPROH2BC to operate reliably in extreme temperatures, high electrical noise, and vibrating environments sets it apart from standard I/O modules. In industries like chemical manufacturing, where the environment can be corrosive and electrically noisy, this module can be trusted to maintain stable data transfer and control. This reliability ensures that critical industrial processes can continue without interruption due to I/O module failures.

Versatile I/O Configuration: Its configurable I/O channels offer great flexibility. In a manufacturing plant with a diverse range of sensors and actuators, the module can be easily configured to interface with different types of devices. For example, it can be set up to handle digital inputs from proximity sensors and digital outputs to control pneumatic valves, allowing for efficient automation of production processes.

Seamless Communication Integration: The support for popular communication protocols like Modbus enables seamless integration with other industrial components. In a large – scale industrial complex with multiple control systems and devices, the module can communicate effectively with PLCs and HMIs. This integration ensures that all parts of the industrial network can work together harmoniously, facilitating efficient monitoring and control of the entire industrial process.

Advanced Diagnostic Capabilities: The comprehensive diagnostic features of the module are a significant advantage. In a power generation plant, where any downtime can lead to substantial losses, the ability of the module to quickly detect and report faults helps maintenance teams to take immediate action. This reduces the time required to identify and fix problems, minimizing the impact on power generation and distribution.

4. Typical Application Scenarios

Industrial Automation in Manufacturing Plants: In modern manufacturing plants, the GE VPROH2B IS215VPROH2BC can be used to connect various sensors and actuators in an automated production line. It can interface with sensors that detect the position of parts on a conveyor belt (digital inputs) and control the operation of robotic arms or packaging machines (digital outputs). This enables real – time monitoring and control of the production process, leading to increased productivity, reduced errors, and improved quality control.

Power Generation and Distribution: In power plants, whether they are coal – fired, gas – fired, or renewable energy – based, this I/O module can play a crucial role. It can be used to connect sensors that monitor parameters such as temperature, pressure, and voltage in the power generation equipment (digital inputs). Based on the data received, it can control actuators such as valves and circuit breakers (digital outputs) to ensure the stable operation of the power generation and distribution processes. In a wind farm, for example, the module can be used to interface with sensors on the wind turbines and control the pitch and yaw mechanisms of the turbines to optimize power generation.

Water and Wastewater Treatment Plants: In water treatment plants, the module can be used to monitor the level of water in tanks, the flow rate of water through pipes, and the quality of treated water using sensors (digital inputs). It can then control pumps, valves, and other equipment (digital outputs) to ensure the efficient treatment and distribution of clean water. In wastewater treatment plants, it can be used to monitor the treatment process and control the operation of sludge – handling equipment, contributing to the proper treatment and disposal of wastewater.

VPROH2B IS215VPROH2BC

5. Related Product Recommendations

GE PLC Systems: To fully utilize the capabilities of the VPROH2B IS215VPROH2BC, GE offers a range of programmable logic controllers (PLCs). These PLCs can be integrated with the I/O module to form a complete control system. For example, the GE PACSystems RX3i series PLCs are highly compatible with the VPROH2B module. They can be programmed to execute complex control algorithms based on the data received from the I/O module, providing advanced control capabilities for industrial processes.

GE HMI Panels: GE also provides human – machine interface (HMI) panels that can be used in conjunction with the VPROH2B IS215VPROH2BC. These HMI panels, such as the C – Mount HMIs, allow operators to monitor and control the industrial process. They can display real – time data from the I/O module, such as the status of sensors and actuators, and enable operators to send control commands. This provides an intuitive interface for operators to interact with the industrial control system, enhancing the overall efficiency of the operation.

6. Installation and Maintenance

Installation: Before installation, ensure that the power to the control system is turned off to prevent electrical hazards. Select a suitable location in the control panel that meets the module’s environmental requirements, such as temperature and humidity. Mount the module on the DIN – rail using the provided mounting hardware, making sure it is securely fastened. Connect the field wires to the appropriate terminals on the module, following the wiring diagram provided in the user manual. After all the connections are made, power on the control system and use the appropriate software to configure the module’s settings, such as the I/O channel configuration and communication protocol settings.

Maintenance: Regularly monitor the status of the module using the diagnostic features. Check for any error messages or abnormal behavior. In dusty or dirty environments, clean the module’s exterior periodically to prevent dust accumulation, which can affect its performance. In case of a fault, refer to the user manual for troubleshooting steps. If the problem persists, contact GE’s technical support for further assistance. Keep the module’s firmware up – to – date by checking GE’s official website for any available updates. Firmware updates often include bug fixes, performance improvements, and new features that can enhance the module’s functionality and reliability.

7. Service and Support

GE provides comprehensive service and support for the VPROH2B IS215VPROH2BC. Their technical support team is available to assist with installation, configuration, and troubleshooting. In case of a product defect or malfunction, GE offers a warranty period, the details of which can be obtained from their official documentation or customer service. Customers can also access a wealth of resources, including user manuals, technical specifications, and application notes, on GE’s online platform. This ensures that users can get the most out of the product and have their issues resolved in a timely manner, minimizing downtime and maximizing the module’s lifespan and performance.