Description

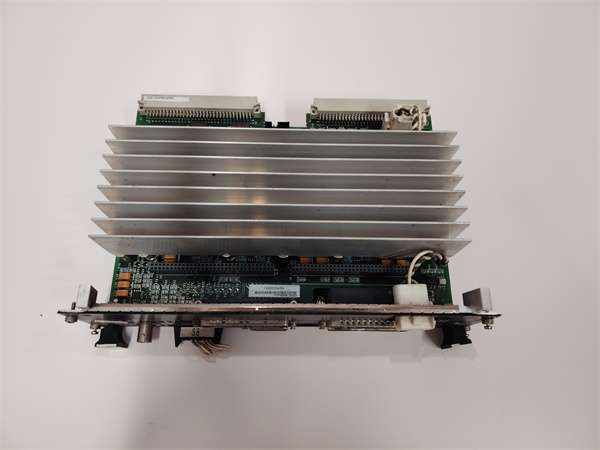

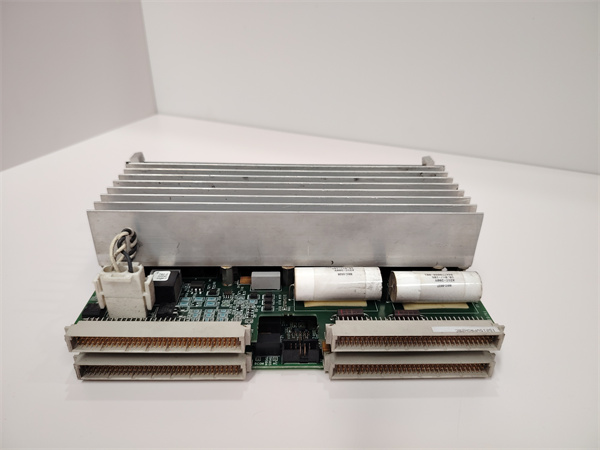

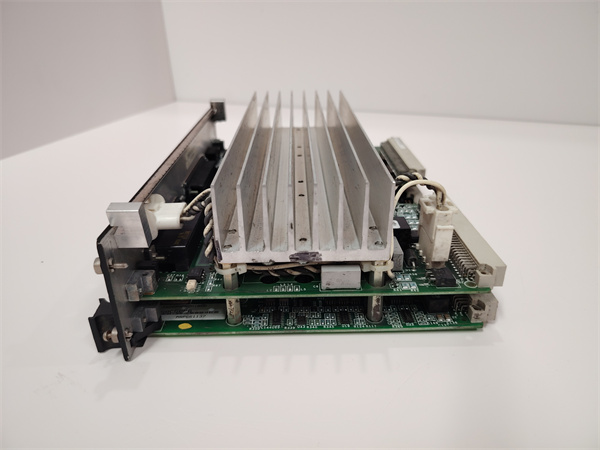

GE VPROH2B IS215VPROH2BC

Product Identification and Nomenclature

The “GE VPROH2B IS215VPROH2BC” is a significant component within GE’s industrial automation and control product lineup. The “VPROH2B” likely serves as the base model identifier, hinting at its functionality within a particular product family. It could be related to valve control, process monitoring, or some other crucial industrial process. The “IS215VPROH2BC” is a more detailed part number. The “IS215” might refer to a specific series or platform within GE’s product range, while the remaining part “VPROH2BC” could distinguish this particular variant. This detailed naming system allows for seamless identification in large – scale industrial projects, inventory management, and when sourcing replacement parts. As an industrial component, it is designed to play a vital role in ensuring the smooth operation of complex industrial systems.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | VPROH2B IS215VPROH2BC |

| Manufacturer | GE (General Electric) |

| Product category | Industrial Automation and Control Component |

| Communication protocols supported | Supports popular industrial communication protocols such as Modbus TCP/IP for seamless integration with a wide range of control systems. It can also communicate via Profibus DP in European – based industrial setups, enabling efficient data transfer between devices in a networked industrial environment. |

| Input/Output capabilities | Equipped with multiple digital inputs and outputs. For example, it may have 8 digital inputs that can be used to receive signals from sensors, switches, or other control devices. On the output side, it could have 4 digital outputs to control relays, solenoids, or other actuators. This allows for effective control and monitoring of industrial processes. |

| Power supply requirements | Operates on a standard 24 VDC power supply, which is common in many industrial settings. It is designed to be energy – efficient, consuming a relatively low amount of power to reduce overall energy costs in industrial plants. The power supply has built – in protection mechanisms against voltage spikes and surges, ensuring reliable operation even in electrically noisy environments. |

| Operating temperature range | Can function within a wide temperature range, typically from – 20 °C to + 60 °C. This makes it suitable for use in various industrial environments, including those in cold storage facilities or hot manufacturing plants. It is also designed to withstand humidity levels up to 95% non – condensing, ensuring reliable performance in damp or humid industrial settings. |

| Physical dimensions | Compact in size, with approximate dimensions of 4.5″ x 3.0″ x 1.5″ (114.3 mm x 76.2 mm x 38.1 mm). This compact design allows for easy installation in control panels, cabinets, or other equipment enclosures, saving valuable space in industrial installations. |

| Weight | Lightweight, weighing approximately 0.8 lbs (0.36 kg). This makes it easy to handle during installation and reduces the stress on mounting structures, enabling flexible mounting options in different industrial setups. |

| Environmental protection | Features a certain level of environmental protection. It may have an IP20 rating, which provides protection against solid objects larger than 12 mm, such as fingers, and against limited amounts of dust. This protection helps to safeguard the internal components of the device from the harsh industrial environment. |

GE VPROH2B IS215VPROH2BC

Product Introduction

The GE VPROH2B IS215VPROH2BC is a highly versatile industrial automation and control component. Its primary function is to interface between different parts of an industrial control system. It can receive input signals from various sensors, such as temperature sensors, pressure sensors, or proximity sensors, and process this information. Based on pre – programmed logic, it can then send out output signals to control actuators like motors, valves, or pumps.

For instance, in a manufacturing plant’s assembly line, the VPROH2B IS215VPROH2BC can be used to monitor the position of components moving along the conveyor belt. Input signals from proximity sensors can be received by the component, and if a component is in the wrong position, it can send an output signal to a pneumatic valve, which will then adjust the position of the component. In a chemical processing plant, it can monitor the temperature and pressure of reaction vessels. If the temperature exceeds a set limit, it can send a signal to a cooling system to start, ensuring the safety and proper operation of the process.

Core Advantages and Technical Highlights

Multi – protocol communication: The ability to support multiple industrial communication protocols like Modbus TCP/IP and Profibus DP is a significant advantage. In a large – scale industrial facility that may have equipment from different manufacturers, this component can communicate with a wide range of devices. For example, it can interface with a GE – branded PLC (Programmable Logic Controller) using Modbus TCP/IP and also communicate with a German – made sensor that uses Profibus DP. This interoperability simplifies the integration process and allows for a more seamless flow of data within the industrial control network.

Flexible I/O capabilities: With its multiple digital inputs and outputs, the VPROH2B IS215VPROH2BC offers great flexibility. In a food packaging plant, the digital inputs can be connected to sensors that detect the presence of products in the packaging machine. The digital outputs can then be used to control the sealing mechanism, the labeling machine, and the conveyor belt speed. This flexibility allows for custom – tailored control solutions in different industrial applications.

Reliable power supply and environmental adaptability: Operating on a standard 24 VDC power supply with built – in protection against voltage spikes makes it reliable in industrial electrical environments. Its wide operating temperature range and ability to withstand high humidity levels ensure that it can function optimally in various industrial settings. In an oil refinery, where the temperature can vary greatly and the air may be humid due to the presence of water in the oil processing, the VPROH2B IS215VPROH2BC can continue to operate without interruption, providing consistent control and monitoring.

Compact and lightweight design: The compact size and lightweight nature of this component are beneficial in industrial installations. In a retrofit project where space is limited in an existing control panel, the small dimensions of the VPROH2B IS215VPROH2BC allow it to be easily installed without requiring major modifications to the panel. Its lightweight design also makes it easy to install in hard – to – reach places, such as on a high – up conveyor belt structure in a mining operation.

Typical Application Scenarios

Manufacturing industry: In automotive manufacturing plants, the VPROH2B IS215VPROH2BC can be used in the robotic assembly lines. It can receive input signals from sensors that detect the position and orientation of car parts. Based on this information, it can send output signals to the robotic arms, controlling their movement for precise assembly. In a textile manufacturing plant, it can monitor the speed of spinning machines and adjust the tension of the threads by controlling the motors, ensuring high – quality fabric production.

Process industries: In a pharmaceutical production facility, it can be used to control the mixing and heating processes. Inputs from temperature and pressure sensors in the mixing tanks can be processed by the component, and it can then control the valves that regulate the flow of raw materials and the heaters that control the temperature. In a water treatment plant, it can monitor the water quality parameters such as pH, turbidity, and chlorine levels. Based on these readings, it can control the pumps that add chemicals for water treatment and the valves that direct the flow of water through different treatment stages.

Energy sector: In a power generation plant, the VPROH2B IS215VPROH2BC can be used to monitor and control the auxiliary systems. It can receive input signals from sensors that detect the oil level, temperature, and vibration of generators’ cooling fans. If any of these parameters are out of the normal range, it can send output signals to start backup fans, adjust the oil pumps, or trigger an alarm. In a wind farm, it can be used to control the pitch of the wind turbine blades based on wind speed and direction sensors, optimizing the power generation efficiency.

GE VPROH2B IS215VPROH2BC

Related Model Recommendations

GE’s other I/O modules in the same series: GE offers other I/O modules in the same product series that may have different numbers of inputs and outputs or support additional communication protocols. For applications that require a larger number of digital inputs, such as a large – scale warehouse with numerous sensors monitoring inventory levels, movement, and security, a module with more inputs can be selected. These modules can be used in combination with the VPROH2B IS215VPROH2BC to expand the control capabilities of an industrial system.

GE’s PLCs and HMI (Human – Machine Interface) devices: To create a comprehensive industrial control system, GE’s PLCs can be paired with the VPROH2B IS215VPROH2BC. The PLC can execute complex control logic based on the input data received from the VPROH2B IS215VPROH2BC. Additionally, an HMI device can be connected to the system, allowing operators to monitor and control the industrial process. In a large – scale manufacturing plant, the PLC can manage the overall production process, while the VPROH2B IS215VPROH2BC interfaces with the sensors and actuators, and the HMI provides a user – friendly interface for operators to interact with the system.

Industrial communication gateways: In cases where the industrial network needs to be extended or integrated with other types of networks, industrial communication gateways can be used in conjunction with the VPROH2B IS215VPROH2BC. For example, if a plant wants to integrate its internal industrial network with an enterprise – level network for remote monitoring and control, a gateway can be used to translate the industrial communication protocols used by the VPROH2B IS215VPROH2BC to a format that can be understood by the enterprise network. This enables better connectivity and remote management of industrial processes.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installation, turn off the power to the industrial system where the component will be installed. Inspect the installation site for any signs of damage, excessive dirt, or moisture. Check the compatibility of the power supply requirements of the VPROH2B IS215VPROH2BC with the available power source. Ensure that the mounting location is suitable and can support the weight of the component. If the installation is in an area with potential electromagnetic interference, consider using shielded cables for connections. Use appropriate tools like screwdrivers and pliers for mounting and wiring.

Commissioning steps: Mount the VPROH2B IS215VPROH2BC in the designated location using the provided mounting hardware. Connect the power cables, ensuring proper polarity. Connect the input and output cables to the relevant sensors and actuators according to the wiring diagram. Power on the industrial system and the component. Use a configuration tool, such as GE’s dedicated software, to set up the communication protocols, input/output assignments, and any other necessary parameters. Test the component by simulating input signals, such as using a signal generator to send signals to the inputs, and verify that the correct output signals are generated and received by the connected devices. Check for any error messages or abnormal behavior in the control system during the testing process.

Maintenance suggestions: Regularly inspect the physical condition of the VPROH2B IS215VPROH2BC, looking for signs of damage, such as cracks in the casing or loose connections. Clean the component periodically to remove any dust or debris that may have accumulated, especially in areas with high – dust environments. Check the power and signal cables for any signs of wear, corrosion, or loose connections. Monitor the performance of the component through the control system, looking for any changes in the input/output response times or incorrect readings. Update the firmware of the component regularly to benefit from the latest performance improvements, bug fixes, and security enhancements. Replace any faulty internal components, such as damaged input/output ports or communication modules, according to the manufacturer’s recommended maintenance schedule.

Service and Guarantee Commitment

GE provides a standard warranty for the VPROH2B IS215VPROH2BC, covering manufacturing defects under normal operating conditions. Their technical support team is available to assist with installation, configuration, and troubleshooting. They offer remote support through phone, email, or online chat platforms, where technicians can guide users through the process of resolving issues. In cases where on – site assistance is required, GE can dispatch service technicians to the customer’s location.

Customers can access a wealth of resources, including detailed user manuals, technical datasheets, and software updates, through GE’s official online portal. Training courses are also available for maintenance and operation personnel. These courses cover topics such as installation, configuration, and basic troubleshooting, ensuring that users can effectively use and maintain the VPROH2B IS215VPROH2BC. Extended warranty options may be available for customers who require additional coverage for a longer period, providing added peace of mind in industrial applications.