Description

Detailed Parameter Table

| Parameter name | Parameter value |

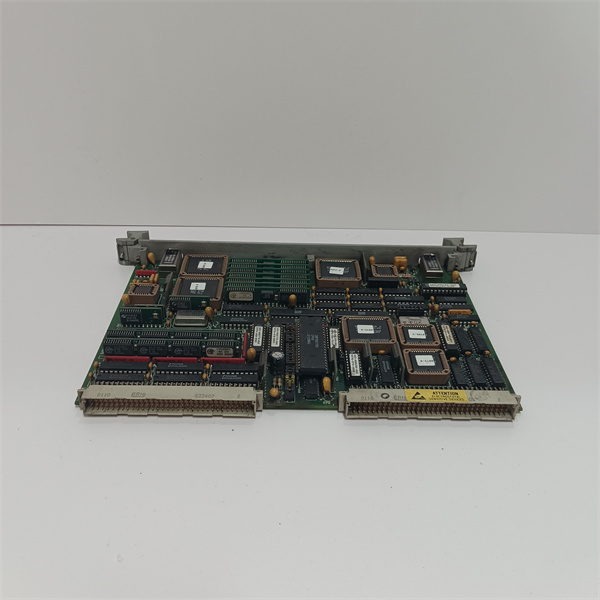

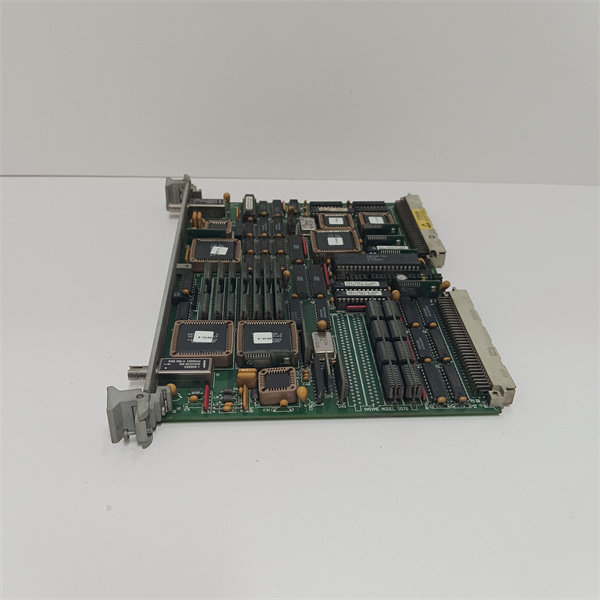

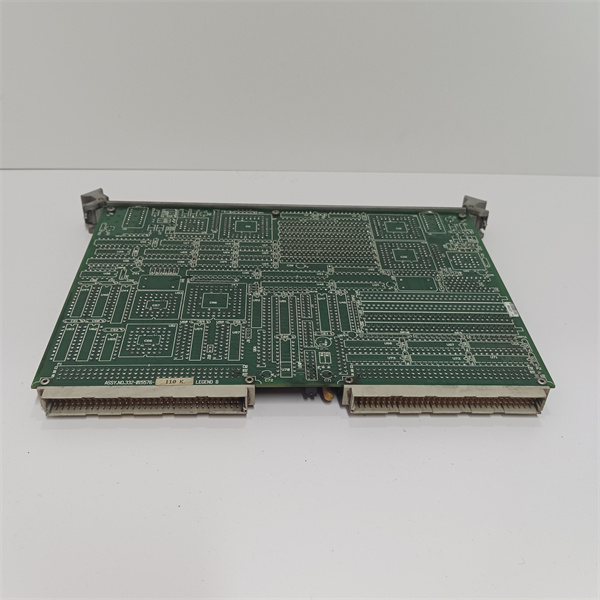

| Product model | VMIVME – 5576 |

| Manufacturer | GE (General Electric) |

| Product category | High – Performance VMEbus Multifunction I/O Board |

| Analog input channels | 16 differential or 32 single – ended |

| Analog input range | ±10V, ±5V, ±2.5V, ±1.25V, 0 – 10V, 0 – 5V, 0 – 2.5V, 0 – 1.25V selectable |

| Resolution | 16 – bit |

| Sampling rate | Up to 100 kS/s per channel |

| Analog output channels | 4 |

| Analog output range | ±10V, 0 – 10V selectable |

| Resolution | 16 – bit |

| Digital input channels | 16 |

| Digital output channels | 16 |

| Digital logic levels | TTL/CMOS compatible |

| Isolation | Opto – isolation for analog and digital I/O, isolation voltage up to 2500 VDC |

| Bus interface | VMEbus, compliant with VME64x standard |

| Memory | On – board SRAM for data buffering, typically 128 KB |

| Form factor | Double eurocard |

| Operating temperature range | 0 °C to 55 °C |

| Storage temperature range | – 20 °C to 70 °C |

| Humidity | 5% – 95% RH non – condensing |

| Dimensions | Approximately 10.6″ x 6.5″ |

| Weight | Approximately 800 g |

| Warranty | 12 months |

GE VMIVME-5576

Product Introduction

The GE VMIVME – 5576 is a high – performance multifunction I/O board designed specifically for VMEbus – based systems. It represents GE’s commitment to providing comprehensive and reliable solutions for industrial automation, test and measurement, and data acquisition applications.

This board integrates a wide range of input and output functions onto a single platform, allowing for seamless interaction between different types of sensors, actuators, and control systems. Its advanced features and robust design make it suitable for use in demanding environments where accuracy, speed, and reliability are of utmost importance.

Core Advantages and Technical Highlights

Versatile analog I/O capabilities: With 16 differential or 32 single – ended analog input channels, the VMIVME – 5576 can handle a diverse range of sensor signals. The selectable input ranges accommodate various sensor outputs, from low – voltage transducers to high – voltage sensors. The 16 – bit resolution ensures precise measurement of analog signals, reducing quantization errors and providing highly accurate data for analysis. The high sampling rate of up to 100 kS/s per channel enables real – time monitoring of rapidly changing signals, such as those in high – speed machinery or power electronics applications.

On the analog output side, the 4 channels with 16 – bit resolution can generate accurate analog signals for controlling actuators, such as servo motors or proportional valves. The selectable output ranges offer flexibility in interfacing with different types of control devices, making it easier to integrate the board into existing systems.

Optical isolation for enhanced safety and reliability: Similar to other GE products, the VMIVME – 5576 incorporates opto – isolation technology for both analog and digital I/O. This isolation provides a high degree of protection against electrical noise, ground loops, and voltage transients. With an isolation voltage of up to 2500 VDC, it can effectively safeguard the board and connected equipment from electrical malfunctions, ensuring stable and accurate operation even in electrically noisy industrial environments.

High – speed data transfer and processing: The board’s compliance with the VME64x standard enables high – speed data transfer between the I/O channels and the host system. The on – board SRAM for data buffering helps to manage the data flow efficiently, reducing the load on the host processor. This is particularly beneficial in applications where large amounts of data need to be acquired and processed in real – time, such as in multi – channel data acquisition systems for industrial monitoring or in complex test and measurement setups.

Flexible digital I/O: The 16 digital input and 16 digital output channels, which are TTL/CMOS compatible, can be used for a variety of purposes. They can interface with digital sensors, such as limit switches or proximity sensors, and control digital actuators, like relays or solenoids. The digital I/O can also be used for status monitoring and control signaling within the system, providing an additional layer of flexibility in system design.

Typical Application Scenarios

Industrial automation: In manufacturing plants, the VMIVME – 5576 can be used to monitor and control a wide range of processes. For example, it can acquire analog signals from temperature, pressure, and flow sensors to regulate industrial processes such as chemical reactions or material handling. The digital I/O can be used to control the operation of conveyor belts, robotic arms, and other automated machinery. The board’s high – speed data acquisition and processing capabilities are well – suited for real – time monitoring and control of production lines, ensuring efficient and accurate operation.

Test and measurement: In a laboratory or test facility, the VMIVME – 5576 can be used to develop and test a variety of electrical and mechanical devices. It can generate precise analog signals to stimulate the device under test and acquire the resulting responses through its analog and digital input channels. For instance, in the testing of power supplies, the board can simulate different load conditions using its analog outputs and measure the output voltage and current with high accuracy using its analog inputs. The digital I/O can be used to control the test equipment’s switches and relays, automating the test process.

Data acquisition in research and development: In research applications, such as in environmental monitoring or experimental physics, the VMIVME – 5576 can be used to collect data from multiple sensors simultaneously. It can interface with a wide range of sensors, including those for measuring humidity, light intensity, and magnetic fields. The board’s high – resolution analog inputs and large number of channels make it suitable for capturing detailed data over long periods. The data can be stored in the on – board memory and transferred to a host computer for further analysis.

Related Model Re

GE VMIVME-5576

commendations

GE VMIVME – 2170A: As previously described, this 32 – bit optically coupled digital output board can be used in combination with the VMIVME – 5576 in industrial control systems. While the VMIVME – 5576 focuses on multifunction I/O with analog and digital capabilities, the VMIVME – 2170A can be used for applications that require a large number of high – current digital outputs, such as directly driving relays or solenoids.

GE D20ME – VME: This VME module can serve as a central processing or communication hub in a system where the VMIVME – 5576 is used for I/O functions. The D20ME – VME offers features such as multiple communication interfaces (RS – 232, RS – 485, Ethernet) and overcurrent protection, which can enhance the overall functionality and reliability of the system. It can communicate with the VMIVME – 5576 over the VMEbus, allowing for seamless integration of data acquisition, control, and communication functions.

GE Mark VIe Series: For more comprehensive plant – wide automation, the GE Mark VIe distributed plant controls (DCS) can be integrated with the VMIVME – 5576. The Mark VIe series streamlines automation across power train equipment, electrical and mechanical distribution, processes, and balance – of – plant (BOP). The VMIVME – 5576 can be used as part of the overall control system’s I/O stage to interface with sensors and actuators throughout the plant, providing the necessary data for the Mark VIe DCS to make informed control decisions.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the VMIVME – 5576, ensure that the VMEbus backplane in which it will be installed is powered off. Use anti – static wristbands and other static – control measures to prevent electrostatic discharge (ESD) damage to the board. Check that the physical dimensions of the installation location are compatible with the board’s double eurocard form factor. Verify that the power supply in the system can meet the board’s power requirements.

Commissioning: Once installed, power on the system. Use the appropriate software or control interface to configure the analog input and output ranges, digital I/O settings, and data transfer parameters according to the requirements of the application. Calibrate the analog inputs and outputs using precision test equipment to ensure accurate measurements and signal generation. Test each I/O channel by sending and receiving signals and verifying the responses. Check for any signs of overheating or abnormal operation during the initial testing phase.

Maintenance suggestions: Regularly perform visual inspections of the VMIVME – 5576 for any signs of physical damage, such as bent pins or discolored components. Check for loose connections on the board and in the VMEbus backplane. Monitor the operating temperature of the board, especially in high – temperature environments, to ensure it remains within the specified range. If any I/O channels fail to operate correctly, use diagnostic tools to check for electrical faults, such as short – circuits or open – circuits. Replace the board if any irreparable damage is detected.

Service and Guarantee Commitment

GE provides a 12 – month warranty for the VMIVME – 5576, covering manufacturing defects and component failures under normal operating conditions. Technical support is available through GE’s customer service channels, where trained technicians can assist with installation, troubleshooting, and any other technical issues related to the board. Customers can access product documentation, including installation manuals and technical specifications, through GE’s official website. In the event of a warranty claim, GE will work to provide a prompt resolution, either through repair or replacement of the faulty board, to minimize downtime for the customer’s operations.