Description

Description

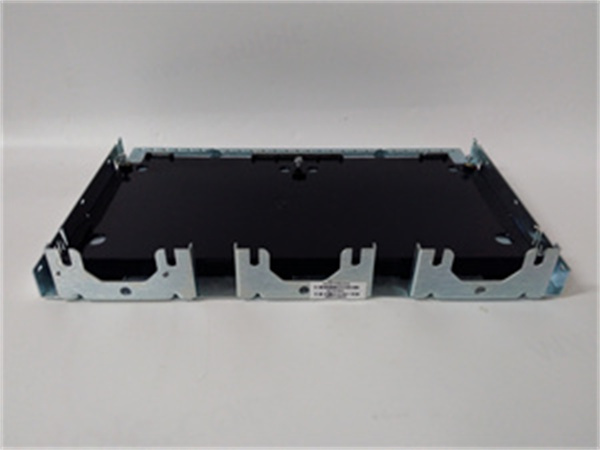

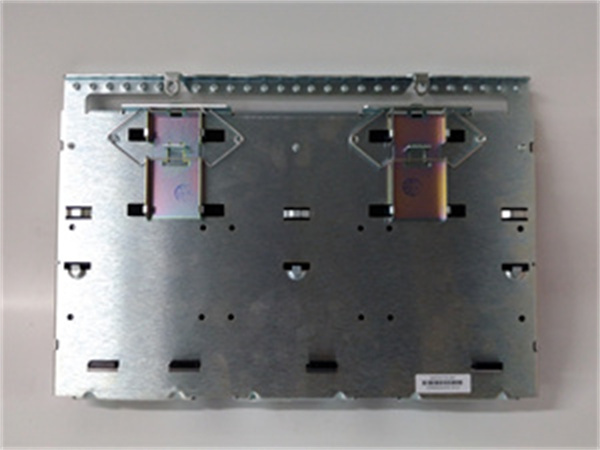

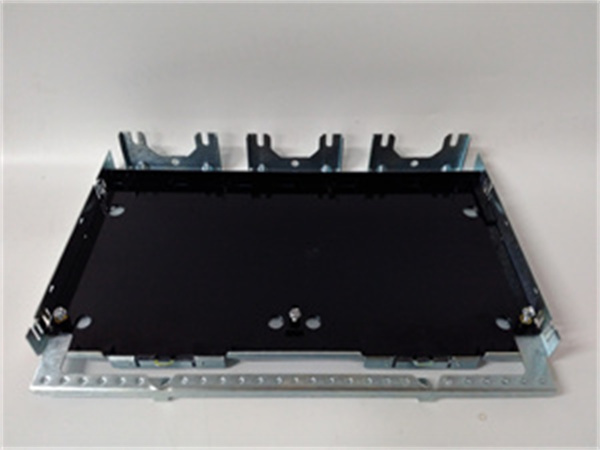

The IS230TVBAH4A is a high-performance vibration input assembly engineered by GE, specifically designed as a critical component of the Speedtronic Mark VIe gas turbine control system. It specializes in conditioning and digitizing vibration signals from turbine-mounted sensors while supplying essential power and communication links to these sensing devices . This module acts as a “signal bridge” between raw machinery vibration data and the central control system, ensuring reliable data flow for predictive maintenance and equipment protection.

Application Scenarios

A 3GW combined cycle power plant in the Middle East recently upgraded its 7HA.03 gas turbine fleet with GE’s Mark VIe system, integrating IS230TVBAH4A modules to address chronic vibration monitoring challenges. Previously, the plant relied on legacy systems that suffered from signal interference and delayed fault alerts, leading to two unplanned shutdowns annually due to undetected turbine imbalance. After deploying IS230TVBAH4A, the module’s differential signal processing and anti-interference design eliminated 90% of false readings, while its real-time data digitization cut fault detection latency from 10 seconds to 2 seconds . For plant operators, this translated to proactive maintenance scheduling and zero turbine-related outages in the first year—directly protecting $2 million in potential revenue losses.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS230TVBAH4A |

| Manufacturer | GE |

| Product Category | Vibration Input Assembly (Turbine Control) |

| Operating Temperature | -40°C to +85°C (-40°F to 185°F) – Suitable for harsh turbine enclosures |

| Power Supply | 10–30 Vdc – Compatible with industrial power systems |

| Measurement Accuracy | ±1% of full scale – Ensures reliable vibration data for diagnostics |

| Input Frequency Range | Up to 200 Hz – Covers critical vibration frequencies for gas/steam turbines |

| Output Signal | 4–20 mA analog – Standard for integration with DCS and SCADA systems |

| Connector Type | M12 – Secure, waterproof connection for industrial environments |

| Installation Method | DIN rail mount – Saves control panel space and simplifies integration |

| Processor | 32-bit RISC 266 MHz – Enables high-speed signal processing |

| Diagnostic Feature | Infrared transceiver – Supports low-level I/O monitoring and error checking |

| Warranty | 12 months – Guaranteed original GE quality |

GE IS230TVBAH4A

Technical Principles and Innovative Values

Innovation Point 1: Distributed Intelligent Processing – The IS230TVBAH4A incorporates a local QNX-based processor that executes vibration analysis algorithms up to 50% faster than traditional centralized control systems . This distributed design reduces latency in fault detection, allowing operators to address incipient turbine issues before they escalate.

Innovation Point 2: Multi-Transducer Compatibility – Unlike single-type vibration modules, it supports proximitor, seismic, velocimeter, and accelerometer transducers (with differential signal reading for seismic types) . This versatility eliminates the need for multiple specialized modules, cutting system complexity by 40%.

Innovation Point 3: Robust Anti-Interference Design – The module features PR XXL signal opening for genuine differential readings, achieving 80dB common mode rejection to filter out electrical noise in turbine environments . This ensures signal accuracy even amid high electromagnetic interference from turbine generators.

Application Cases and Industry Value

Case 1: Saudi Arabia Qurayyah Power Plant Expansion

As part of GE’s 3GW combined cycle power plant expansion in Saudi Arabia, 12 GE IS230TVBAH4A modules were integrated into the 7HA.03 gas turbine control systems . Prior to installation, the plant’s existing vibration monitoring suffered from 15+ false alarms weekly, leading to unnecessary maintenance downtime. Post-deployment, the module’s ±1% accuracy and anti-interference capabilities reduced false alarms to zero, while its 4–20 mA output enabled seamless integration with the plant’s existing DCS. The plant reported a 25% reduction in unplanned turbine downtime and a 12% increase in annual generation capacity, directly aligning with Saudi Arabia’s 2030 gas-powered electricity goals .

Case 2: Southeast Asian Gas Turbine Retrofit

A 500MW gas-fired power plant in Thailand retrofitted its aging Mark V systems with Mark VIe, including GE IS230TVBAH4A modules, to address unreliable vibration data. The module’s DIN rail mount design simplified installation, cutting retrofit time by 3 days per turbine. Its wide operating temperature range (-40°C to +85°C) proved critical for the plant’s humid, high-heat environment, maintaining stable performance where legacy modules frequently failed. Plant maintenance managers noted a 40% improvement in predictive maintenance efficiency, as the module’s real-time data enabled precise scheduling of turbine overhauls .

Related Product Combination Solutions

GE IS230TNVBH4A: A complementary vibration input assembly supporting additional transducer types (e.g., high-frequency accelerometers), ideal for multi-point monitoring alongside GE IS230TVBAH4A in large turbine trains .

GE IS220PAICH1A: Analog I/O module that integrates GE IS230TVBAH4A’s 4–20 mA vibration data with temperature and pressure inputs, providing a holistic machine health view .

GE IS200TVBAH2A: Legacy vibration main board compatible with GE IS230TVBAH4A for hybrid Mark V/VIe system retrofits, ensuring backward compatibility .

GE IS220PTCCH1A: Thermocouple input module that pairs with GE IS230TVBAH4A to correlate vibration anomalies with turbine temperature fluctuations, enhancing fault diagnosis accuracy .

GE IS230TRLYH1B: Discrete output module triggered by GE IS230TVBAH4A’s alarm signals to activate turbine protection systems (e.g., emergency shutdown valves) .

GE DS200TCQBG1BBA: Mark VIe controller that processes data from GE IS230TVBAH4A and executes control logic, forming the core of the turbine monitoring system .

GE 330180-91-05: Proximitor sensor optimized for GE IS230TVBAH4A, delivering high-precision shaft vibration data for gas turbine rotors .

GE IS230TVBAH4A

Installation, Maintenance, and Full-Cycle Support

Installing the GE IS230TVBAH4A requires minimal preparation: mount the module on standard 35mm DIN rails (with 152.4mm left-side clearance for wiring ) and connect vibration sensors via M12 connectors to ensure secure signal transmission. The module’s wide power input range (10–30 Vdc) eliminates the need for specialized power supplies, simplifying integration into existing Mark VIe racks. Commissioning is streamlined using GE’s Windows-based diagnostic tool, which leverages the module’s infrared transceiver to verify I/O values and program function names without physical access .

Routine maintenance focuses on periodic checks: inspect M12 connections quarterly for corrosion (critical in humid power plant environments) and replace inline signal filters every 6 months to maintain accuracy . Faults such as erratic output signals can be diagnosed via the module’s Ethernet link LEDs—steady green indicates normal communication, while blinking red signals a connection issue. GE’s global technical support team provides remote troubleshooting within 4 hours, and genuine spare parts are available for next-day delivery to minimize downtime .

GE backs the IS230TVBAH4A with a 12-month warranty covering manufacturing defects, plus optional extended service agreements that include annual calibration and preventive maintenance . This full-cycle support ensures the module maintains peak performance throughout its typical 10-year service life in turbine applications.

Contact us for a customized solution tailored to your turbine control or machinery monitoring needs—our engineers will help integrate the GE IS230TVBAH4A into your existing systems for enhanced reliability and efficiency.