Description

DS3800NRTB1A: Product Overview

The DS3800NRTB1A is a daughterboard-grade RTD conditioning module that plugs onto a motherboard carrier inside the Mark IV rack. It measures resistance changes in PT100 or PT1000 RTD probes (typically installed on bearings, combustion cans, steam lines, or generator windings) and converts them into 0–10 V or 4–20 mA signals that are fed to the Mark IV A/D cards for temperature limiting, thermal protection, and efficiency calculations. The card is hardware-configured (no firmware) and deterministic, making it suitable for safety-related temperature monitoring when triple-redundant.

Physical implementation includes precision current sources, lead-wire compensation, op-amp stages, and 1500 V AC galvanic isolation. 3-wire or 4-wire connections are jumper-selectable to cancel cable resistance and ensure ±0.1 % accuracy over long cable runs. Front-edge LEDs (green = channel active, red = open-circuit or over-range) give real-time sensor health—no multimeter required during commissioning.

Environmental qualification meets –20 °C to +70 °C and 95 % RH non-condensing, permitting installation in turbine auxiliaries or control rooms with minimal HVAC. IEEE 344 form-factor ensures mechanical compatibility across decades of Mark IV production.

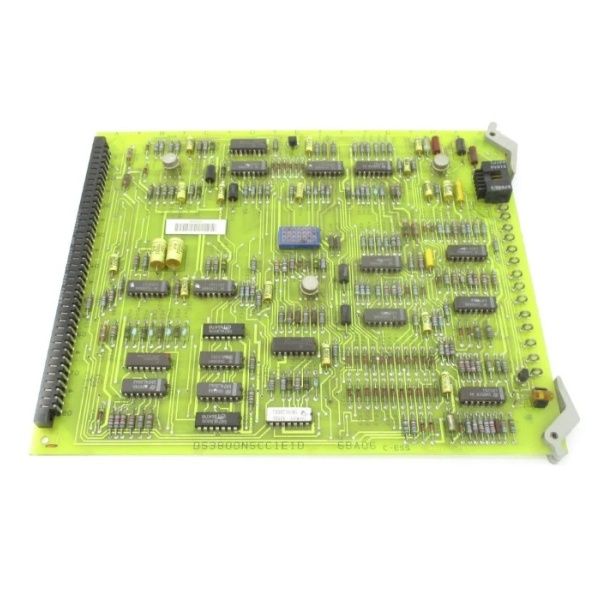

GE DS3800NSCC1E1D

DS3800NRTB1A: Technical Specifications

-

Model Number: DS3800NRTB1A

-

Manufacturer: General Electric (GE Energy)

-

Product Type: RTD Conditioning Card

-

Sensor Type: PT100, PT1000, Cu100 (jumper-selectable)

-

Connection: 3-wire or 4-wire (jumper-selectable per channel)

-

Input Range: 0–400 Ω (expandable to 600 Ω with jumper)

-

Output Range: 0–10 V or 4–20 mA (jumper-selectable)

-

Accuracy: ±0.1 % of span @ 25 °C (±0.25 % over -20–70 °C)

-

Isolation: 1500 V AC channel-to-ground, 500 V channel-to-channel

-

Excitation Current: 1 mA constant-current source per RTD

-

Lead-Wire Compensation: Automatic 3-/4-wire cancellation

-

Surge Protection: TVS diodes on every input, >500 V clamp

-

Connectors: 20-pin ribbon, keyed, gold-plated

-

Power Rails: +5 V logic, ±15 V analog, <0.3 W per channel

-

LEDs: Green = channel active, Red = open-circuit or over-range

-

Temp Range: -20 °C to +70 °C operational, -40 °C to +85 °C storage

-

Certifications: CE, RoHS, IEEE 344 form-factor compatible

Core Features & Customer Value

3-/4-Wire Compensation for Long Cable Runs

Automatic lead-resistance cancellation eliminates ohmic error caused by hundreds of metres of cable, ensuring ±0.1 % accuracy for bearing or combustor temperature monitoring without external compensation boxes.

Automatic lead-resistance cancellation eliminates ohmic error caused by hundreds of metres of cable, ensuring ±0.1 % accuracy for bearing or combustor temperature monitoring without external compensation boxes.

Hot-Swappable Sensor Channels

Daughterboard form allows online replacement of one RTD card in TMR racks; remaining two legs continue voting, achieving >99.97 % availability on combined-cycle fleets.

Daughterboard form allows online replacement of one RTD card in TMR racks; remaining two legs continue voting, achieving >99.97 % availability on combined-cycle fleets.

Field-Configurable Without Software

Jumpers select sensor type, wire count, and output range—technician can swap from PT100 to PT1000 or from 3-wire to 4-wire using only a tweaker and a DMM, no laptop required.

Jumpers select sensor type, wire count, and output range—technician can swap from PT100 to PT1000 or from 3-wire to 4-wire using only a tweaker and a DMM, no laptop required.

Surge-Hardened for Turbine Deck

TVS diodes clamp >500 V spikes from lightning, VFD switching, or exciter flash-over. 1500 V isolation prevents ground-fault propagation to CPU cards, reducing unplanned replacement by >60 % compared with non-isolated RTD cards.

TVS diodes clamp >500 V spikes from lightning, VFD switching, or exciter flash-over. 1500 V isolation prevents ground-fault propagation to CPU cards, reducing unplanned replacement by >60 % compared with non-isolated RTD cards.

GE DS3800NSCC1E1D

Typical Applications

Gas Turbine Bearing Temperature Monitoring

Primary RTD interface for Frame 7/9 heavy-duty units: measures bearing metal and lube-oil outlet temperatures, outputs 4–20 mA to Mark IV A/D, enabling thermal protection and predictive maintenance alarms.

Primary RTD interface for Frame 7/9 heavy-duty units: measures bearing metal and lube-oil outlet temperatures, outputs 4–20 mA to Mark IV A/D, enabling thermal protection and predictive maintenance alarms.

Steam Turbine Stator & Steam-Pipe Monitoring

4-wire PT100 inputs on generator stator slots and steam-pipe thermowells—compensated accuracy prevents false over-temperature trips during load ramps or start-ups.

4-wire PT100 inputs on generator stator slots and steam-pipe thermowells—compensated accuracy prevents false over-temperature trips during load ramps or start-ups.

Remote Site & Island Mode Operation

Long-cable RTD runs (up to 500 m) from offshore compressor skids are automatically compensated, eliminating need for local transmitters and reducing cable count by 40 % .

Long-cable RTD runs (up to 500 m) from offshore compressor skids are automatically compensated, eliminating need for local transmitters and reducing cable count by 40 % .