Description

DS3800NPSS1E1D: Product Overview

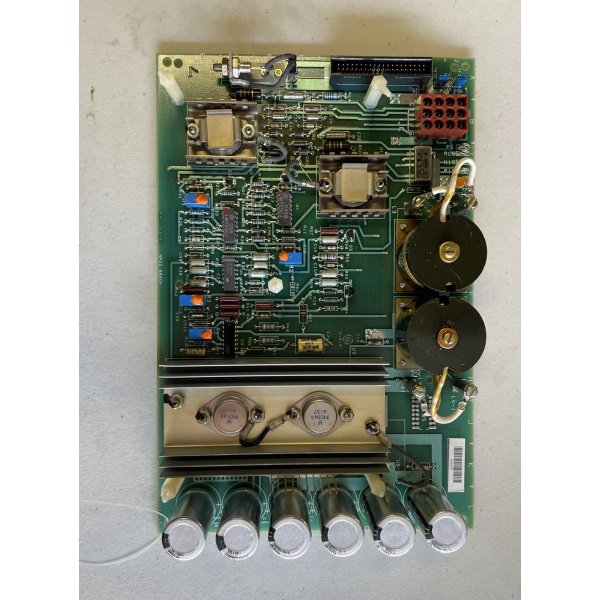

The board serves as a personality and power distribution interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this module functions as the critical adaptation layer between the standardized Mark IV backplane and site-specific field requirements. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, providing the customized signal conditioning and power regulation necessary to match diverse auxiliary equipment and I/O configurations.

As a personality board, the unit integrates both power supply functions and configurable signal interface capabilities. It receives primary power from the rack distribution system and provides regulated, filtered outputs to sensitive I/O circuits while simultaneously handling personality-specific signal conditioning. The board’s architecture supports the “personality” concept central to Mark IV flexibility—using socketed EPROMs and field-adjustable components to adapt the same hardware base to different turbine models, frame sizes, and auxiliary configurations without manufacturing variations.

The board features multiple trimmer potentiometers accessible from the front panel, enabling qualified technicians to calibrate voltage levels, signal gains, and timing parameters during commissioning or maintenance. Diagnostic LEDs provide immediate visual confirmation of power rail status and operational states, facilitating rapid troubleshooting without diagnostic software connections. The high-density modular backplane connector ensures reliable power and signal distribution while retention levers prevent vibration-induced loosening.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture allows this personality interface to operate autonomously while maintaining deterministic synchronization with the central control processors.

DS3800NPSS1E1D: Technical Specifications

-

Model Number: DS3800NPSS1E1D

-

Manufacturer: General Electric

-

Product Type: Personality Power Supply System Board

-

Series: GE Speedtronic Mark IV

-

Personality Configuration: EPROM-based firmware for site-specific application code

-

Field Calibration: Multiple trimmer potentiometers (typical N-series configuration)

-

Power Function: Regulated power distribution to I/O circuits (derived from rack supply)

-

Status Indication: Diagnostic LEDs for power and operational status

-

Backplane Interface: High-density modular connector (AMD 218A4553-1 compatible)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

-

Configuration: Hardware jumpers for operational mode selection

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Physical Construction: Multi-layer PCB with socketed memory and calibration components

GE DS3800NPSS1E1D

Part 4: Core Features & Customer Value

Field-Configurable Personality Architecture: The board utilizes socketed EPROM modules to store site-specific personality firmware, allowing the same hardware to support different turbine models and application codes through software configuration rather than manufacturing changes. This architecture enables rapid adaptation during commissioning—technicians can load frame-specific fuel curves, I/O mappings, or auxiliary sequences by replacing the personality chip rather than swapping entire boards. For fleets with mixed turbine configurations, this reduces spare parts inventory requirements and simplifies logistics.

Integrated Power Regulation and Filtering: Unlike pure signal interface boards, the NPSS integrates power supply regulation to provide clean, stable voltage rails for personality-specific I/O circuits. The onboard filtering capacitors and regulation circuitry protect sensitive logic from voltage transients generated by high-power auxiliary switching. This integration eliminates the need for separate power conditioning modules for personality I/O, reducing rack space requirements and inter-board wiring complexity.

Extensive Field Calibration Capability: The front-accessible trimmer potentiometers allow precise adjustment of signal levels, threshold voltages, and timing parameters without removing the board or accessing software tools. This hardware-level calibration is essential for matching the interface to specific field devices—such as adjusting voltage dividers for different sensor ranges or compensating for cable length variations in analog loops. Technicians can optimize performance during startup and make fine adjustments over the equipment lifecycle to compensate for component aging.

Comprehensive Diagnostic Visibility: The diagnostic LEDs provide immediate indication of power rail integrity, EPROM initialization status, and fault conditions. During commissioning, these indicators confirm that personality firmware has loaded correctly and that power supplies are within specification before the main control software is brought online. For maintenance technicians, LED patterns indicate whether faults originate in power supply circuits, signal conditioning sections, or external field wiring, reducing diagnostic time during urgent repairs.

Robust Industrial Design for Long-Term Reliability: The board utilizes industrial-grade passive components and socketed memory devices rated for extended temperature operation. The retention levers ensure positive backplane engagement despite turbine-induced vibration, while the modular connector system facilitates hot-swappable replacement in TMR configurations. Given the obsolete status of the Mark IV platform, this design longevity is critical—facilities must maintain operational availability for decades, and the board’s construction ensures extended service life with minimal maintenance beyond periodic calibration verification.

Part 5: Typical Applications

Mixed Fleet Turbine Support:

The DS3800NPSS1E1D is deployed across GE Frame 5, 6, 7, 9, and LM aeroderivative installations to provide standardized personality interfaces that accommodate different turbine configurations. In utility fleets operating multiple frame sizes, the board’s personality EPROMs can be configured for specific fuel systems, starting sequences, or cooling configurations while maintaining common hardware spares. The field trimmers calibrate the interface for the specific analog sensors used on each frame—whether thermocouples, RTDs, or pressure transmitters—with different scaling requirements.

The DS3800NPSS1E1D is deployed across GE Frame 5, 6, 7, 9, and LM aeroderivative installations to provide standardized personality interfaces that accommodate different turbine configurations. In utility fleets operating multiple frame sizes, the board’s personality EPROMs can be configured for specific fuel systems, starting sequences, or cooling configurations while maintaining common hardware spares. The field trimmers calibrate the interface for the specific analog sensors used on each frame—whether thermocouples, RTDs, or pressure transmitters—with different scaling requirements.

Site-Specific I/O Adaptation:

In retrofit applications where Mark IV controls interface with non-GE auxiliary equipment or legacy field devices, the board provides the signal conditioning and voltage level translation necessary for compatibility. The trimmer adjustments match input ranges to existing transmitters, while personality firmware implements custom logic sequences for auxiliary equipment that predates the Mark IV installation. This adaptation capability allows turbine controls to be modernized without replacing operational auxiliary systems, reducing capital expenditure and outage duration.

In retrofit applications where Mark IV controls interface with non-GE auxiliary equipment or legacy field devices, the board provides the signal conditioning and voltage level translation necessary for compatibility. The trimmer adjustments match input ranges to existing transmitters, while personality firmware implements custom logic sequences for auxiliary equipment that predates the Mark IV installation. This adaptation capability allows turbine controls to be modernized without replacing operational auxiliary systems, reducing capital expenditure and outage duration.

Power Plant Auxiliary Control Systems:

The board manages personality interfaces for auxiliary systems such as lube oil consoles, hydraulic power units, and cooling water systems. It provides the regulated power and signal conditioning for auxiliary motor contactors, valve positioners, and pump controls that operate on different voltage levels than the primary Mark IV logic. The integrated power regulation ensures that auxiliary I/O operates reliably despite voltage fluctuations in the plant 125VDC battery system or 480VAC motor control centers.

The board manages personality interfaces for auxiliary systems such as lube oil consoles, hydraulic power units, and cooling water systems. It provides the regulated power and signal conditioning for auxiliary motor contactors, valve positioners, and pump controls that operate on different voltage levels than the primary Mark IV logic. The integrated power regulation ensures that auxiliary I/O operates reliably despite voltage fluctuations in the plant 125VDC battery system or 480VAC motor control centers.

Fuel System Personality Interfacing:

In gas turbine applications utilizing different fuel types (natural gas, distillate, dual-fuel), the board can be configured via personality EPROM to support the specific fuel control valves, flow meters, and pressure regulators for each fuel system. The trimmer potentiometers calibrate the analog interface for different valve positioner ranges (e.g., 4-20mA vs. 10-50mA), allowing the same control software to interface with diverse valve hardware through hardware personality configuration rather than software modifications.

In gas turbine applications utilizing different fuel types (natural gas, distillate, dual-fuel), the board can be configured via personality EPROM to support the specific fuel control valves, flow meters, and pressure regulators for each fuel system. The trimmer potentiometers calibrate the analog interface for different valve positioner ranges (e.g., 4-20mA vs. 10-50mA), allowing the same control software to interface with diverse valve hardware through hardware personality configuration rather than software modifications.