Description

DS3800NISB1F1E: Product Overview

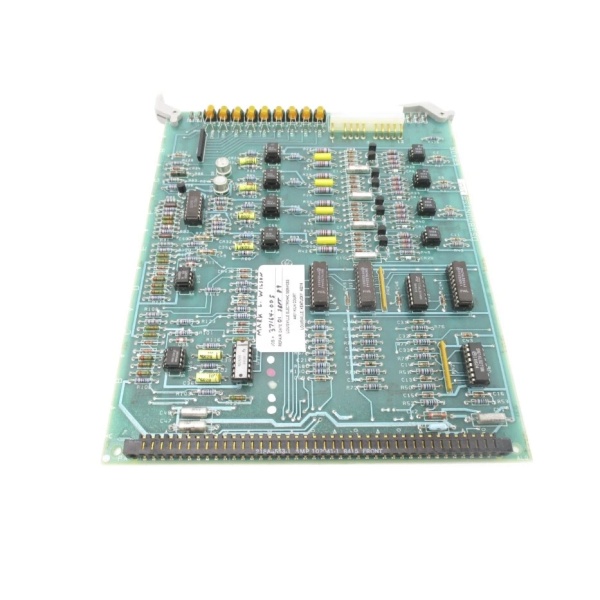

The DS3800NISB1F1E serves as a critical protective interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned between field-mounted instrumentation and the system’s sensitive processing electronics, this card provides galvanic isolation that prevents ground loop currents and transient voltage events from propagating into the control system. The “NIS” designation identifies this as a network/signal isolation module optimized for the electrically noisy environments typical of power generation facilities.

The board incorporates multiple isolation channels, each featuring transformers or optocouplers that separate field wiring from internal control circuits while preserving signal integrity. This isolation architecture protects against common-mode voltage differences that can occur when field devices are located hundreds of feet from the control cabinet, often in areas with divergent ground potentials. The conditioned, isolated signals are then transmitted via the Mark IV’s triple-modular-redundant (TMR) backplane to the system’s main processors for voting and control action.

As a member of the DS3800 series, the NISB1F1E adheres to the standardized form factor and connector scheme established for the Mark IV platform. This standardization enables rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The board’s design reflects GE’s field-hardened engineering philosophy: conservative component ratings, extensive use of socketed integrated circuits for maintainability, and robust mechanical retention features that withstand decades of thermal cycling and vibration in power plant environments.

DS3800NISB1F1E

DS3800NISB1F1E: Technical Specifications

-

Model Number: DS3800NISB1F1E

-

Manufacturer: General Electric

-

Product Type: Signal Isolation Card

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Isolation Method: Galvanic isolation (transformer or optocoupler based)

-

Channel Configuration: Multi-channel input isolation

-

Backplane Interface: Ribbon cable connector with retention hardware

-

Signal Types: Compatible with analog and discrete field signals

-

Isolation Rating: Standard industrial isolation voltage (typically 500V-1000V channel-to-channel and channel-to-ground)

-

Input Protection: Transient voltage suppression on field-side inputs

-

Mounting: Standard DS3800 series card cage with retention clips

-

Operating Environment: Industrial control room, forced air cooling recommended

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

Ground Loop Elimination for Signal Integrity: The primary function of the NISB1F1E is to break galvanic continuity between field wiring and control electronics, eliminating ground loop currents that can introduce noise or damage sensitive components. In large industrial facilities, ground potential differences of tens of volts can exist between the control room and remote field devices. Without isolation, these potential differences drive currents through signal cables, creating measurement errors or hardware failures. For plant operators, this isolation ensures that control decisions are based on accurate process measurements rather than electrical noise artifacts.

Transient Protection for Equipment Longevity: Turbine control systems operate in environments with significant electromagnetic interference sources—high-voltage switchgear, variable frequency drives, and lightning-induced transients. The NISB1F1E incorporates surge protection devices on field-side inputs that clamp voltage transients before they reach internal electronics. This protection extends the operational life of downstream processing boards and reduces the frequency of unplanned outages caused by electrical damage. The isolation barrier itself provides additional protection by physically separating high-energy field circuits from low-voltage logic circuits.

Maintainable Design for Reduced Downtime: The board’s use of socketed integrated circuits and standardized connectors facilitates rapid field replacement. When isolation channels fail—often indicated by diagnostic alarms or erratic signal readings—technicians can replace the entire card without recalibration, as the isolation function is largely transparent to signal scaling. The standardized DS3800 form factor ensures mechanical compatibility across decades of production, protecting investment in spare parts inventory and technician training. This maintainability is critical for baseload power plants where availability premiums are high.

DS3800NISB1F1E

Typical Applications

The DS3800NISB1F1E is deployed in gas turbine analog input systems, where it isolates signals from temperature transmitters, pressure transducers, and flow sensors located on the turbine deck or in auxiliary skids. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple NIS boards operate in conjunction with current loop input boards—each providing isolation for specific sensor groups before signal conditioning and analog-to-digital conversion. The isolation ensures that ground faults in field wiring do not propagate to the TMR processing channels.

In steam turbine supervisory instrumentation, this card isolates signals from proximity probes monitoring shaft vibration, eccentricity detectors, and phase reference sensors. These measurements require high signal integrity to detect mechanical faults measured in thousandths of an inch. The NISB1F1E’s isolation prevents ground noise from masking subtle vibration signatures that indicate bearing wear or rotor instability, enabling predictive maintenance strategies that avoid catastrophic failures.

The module also serves in turbine auxiliary system control, isolating discrete inputs from limit switches, pressure switches, and valve position indicators in lube oil, cooling water, and fuel gas systems. In these applications, the card protects against wiring faults that could otherwise damage multiple control channels simultaneously. The isolation barrier ensures that a single field short circuit affects only one channel, maintaining TMR system integrity.