Description

DS3800NEPD1F1C: Product Overview

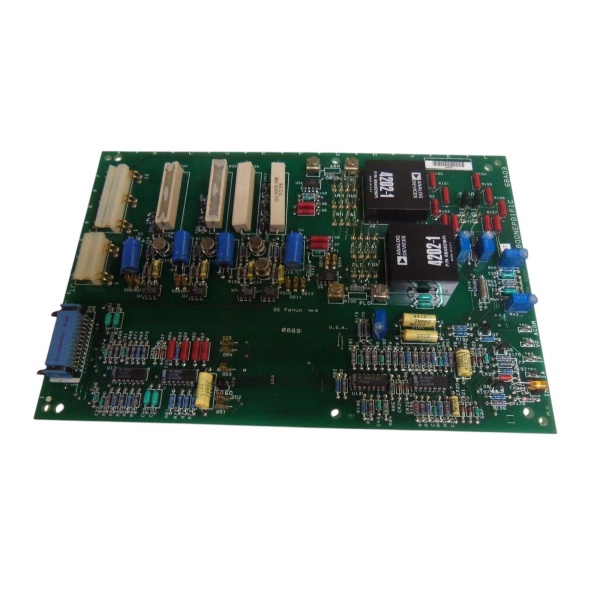

The board serves as an expander personality driver within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this module functions as the intelligent interface between the standardized Mark IV backplane and site-specific I/O configurations, managing the personality-based adaptation required for diverse turbine applications. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that I/O expansion modules are properly configured and driven according to the specific requirements of the installation.

As an expander personality driver, the unit provides the firmware storage and signal conditioning necessary to adapt generic I/O hardware to specific field device requirements. It hosts the personality EPROMs that define I/O scaling, signal ranges, and communication protocols for expansion modules, while providing the drive capability necessary to source or sink current for field devices. The board manages the data exchange between the central microprocessors and distributed I/O points, ensuring that signals are properly conditioned and isolated.

The board features dual high-density modular backplane connectors that interface with the Mark IV rack, providing both primary and expansion connectivity paths. Multiple configuration jumpers allow adaptation to different addressing schemes and operational modes, while the retention levers ensure mechanical stability in the high-vibration environment of turbine control enclosures.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires that personality configuration be maintained at the board level to support rapid replacement without software reconfiguration.

DS3800NEPD1F1C: Technical Specifications

-

Model Number: DS3800NEPD1F1C

-

Manufacturer: General Electric

-

Product Type: Expander Personality Driver Board

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Function: Personality firmware host and I/O drive interface for expansion modules

-

Backplane Interface: Dual high-density modular connectors (AMD 218A4553-1 compatible)

-

Memory: EPROM sockets for personality configuration and I/O mapping firmware

-

Configuration: Multiple hardware jumpers for addressing and operational mode selection

-

Drive Capability: Buffered logic outputs for I/O module control and field device interfacing

-

Status Indication: Diagnostic LEDs for power and operational status

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

-

Power Supply: Derived from Mark IV rack backplane (+5 VDC logic, ±15V analog driver supplies)

GE DS3800NEPD1F1C

Part 4: Core Features & Customer Value

Personality-Based I/O Adaptation: The board hosts the firmware personality that tailors generic I/O expansion hardware to specific field requirements. Through socketed EPROMs, the board stores I/O scaling maps, signal conditioning parameters, and device-specific configuration data. This allows the same physical I/O hardware to support different sensor types, voltage ranges, and auxiliary equipment across diverse turbine models without hardware modifications. For maintenance personnel, this means that replacement boards can be quickly configured by transferring the personality EPROMs, reducing spare parts inventory complexity.

Dual Connectivity for Expansion Flexibility: The dual backplane connectors provide both primary system integration and expansion bus connectivity, allowing the board to interface with both the central processing rack and distributed I/O expansion racks. This architecture supports large-scale turbine installations with extensive I/O requirements spread across multiple enclosures, while maintaining deterministic communication timing essential for real-time control.

Robust Driver Circuitry for Field Interfacing: The board incorporates buffered driver circuits capable of sourcing or sinking the current required for field device activation and signal transmission. These drivers provide the electrical muscle necessary to control discrete outputs, drive indicator lamps, and interface with relay coils while maintaining optical or galvanic isolation from the sensitive microprocessor logic. For field engineers, this means reliable operation with legacy field devices that may present non-standard loads or require specific voltage levels.

Comprehensive Configuration via Hardware Jumpers: Multiple jumper configurations allow field adaptation of addressing, termination, and operational modes without software tools or programming equipment. This hardware-level configuration is essential for matching the board to specific rack positions, addressing schemes, or expansion topologies during installation or retrofit projects. The jumpers provide immediate visual confirmation of configuration settings, reducing the risk of addressing conflicts during commissioning.

Hot-Swappable Design with Secure Retention: The retention lever system ensures positive mechanical engagement with the backplane while facilitating rapid replacement during maintenance activities. In TMR configurations, the board can be replaced while the turbine remains operational on redundant channels, ensuring that I/O expansion capabilities are restored quickly without requiring process shutdowns or startup interruptions.

Part 5: Typical Applications

Large Gas Turbine I/O Expansion Systems:

The DS3800NEPD1F1C is deployed in GE Frame 5, 6, 7, and 9 gas turbines with extensive I/O requirements for exhaust temperature monitoring, vibration protection, and auxiliary control. In these applications, the board manages the personality configuration for distributed I/O modules located throughout the turbine skid, ensuring that signals from thermocouples, proximity probes, and pressure transmitters are properly scaled and transmitted to the central processors. The dual connectors facilitate expansion beyond the main control rack to remote I/O stations near the turbine.

The DS3800NEPD1F1C is deployed in GE Frame 5, 6, 7, and 9 gas turbines with extensive I/O requirements for exhaust temperature monitoring, vibration protection, and auxiliary control. In these applications, the board manages the personality configuration for distributed I/O modules located throughout the turbine skid, ensuring that signals from thermocouples, proximity probes, and pressure transmitters are properly scaled and transmitted to the central processors. The dual connectors facilitate expansion beyond the main control rack to remote I/O stations near the turbine.

Steam Turbine Retrofit and Modernization:

In steam turbine control upgrades, this board provides the interface between modern Mark IV processors and existing field wiring through expansion I/O modules. It hosts the personality firmware that maps legacy signal ranges (such as 10-50mA or 1-5VDC) to modern control standards while providing the drive capability to interface with existing field devices. This allows turbine controls to be modernized without wholesale replacement of field instruments, reducing project costs and commissioning time.

In steam turbine control upgrades, this board provides the interface between modern Mark IV processors and existing field wiring through expansion I/O modules. It hosts the personality firmware that maps legacy signal ranges (such as 10-50mA or 1-5VDC) to modern control standards while providing the drive capability to interface with existing field devices. This allows turbine controls to be modernized without wholesale replacement of field instruments, reducing project costs and commissioning time.

Aeroderivative Package Expansion:

For LM6000 and LM2500 units requiring additional I/O points beyond the base configuration, this board expands the system’s capability to monitor package auxiliaries such as fuel forwarding systems, compartment ventilation, and hydraulic control units. The board’s configuration flexibility accommodates the specific wiring practices and signal types common to aeroderivative installations, which often differ from heavy-duty frame turbine standards.

For LM6000 and LM2500 units requiring additional I/O points beyond the base configuration, this board expands the system’s capability to monitor package auxiliaries such as fuel forwarding systems, compartment ventilation, and hydraulic control units. The board’s configuration flexibility accommodates the specific wiring practices and signal types common to aeroderivative installations, which often differ from heavy-duty frame turbine standards.

Combined Cycle Plant Distributed I/O:

In combined cycle power plants where the Mark IV controls must interface with heat recovery steam generators (HRSG), steam turbines, and balance-of-plant equipment, this board manages the personality configuration for I/O distributed across multiple control cabinets. It ensures that signals from remote equipment are properly conditioned and that the addressing scheme maintains compatibility with the central control architecture, supporting coordinated operation of the entire power generation complex.

In combined cycle power plants where the Mark IV controls must interface with heat recovery steam generators (HRSG), steam turbines, and balance-of-plant equipment, this board manages the personality configuration for I/O distributed across multiple control cabinets. It ensures that signals from remote equipment are properly conditioned and that the addressing scheme maintains compatibility with the central control architecture, supporting coordinated operation of the entire power generation complex.

Safety Instrumented System Expansion:

Within the Mark IV’s integrated protection architecture, this board provides the expansion capability necessary for comprehensive safety monitoring, including additional vibration channels, temperature monitors, and emergency shutdown inputs. The personality firmware configures these inputs according to safety integrity level (SIL) requirements, ensuring that protection functions are properly scaled and voted according to industry safety standards.

Within the Mark IV’s integrated protection architecture, this board provides the expansion capability necessary for comprehensive safety monitoring, including additional vibration channels, temperature monitors, and emergency shutdown inputs. The personality firmware configures these inputs according to safety integrity level (SIL) requirements, ensuring that protection functions are properly scaled and voted according to industry safety standards.