Description

DS3800NDAC1B1C: Product Overview

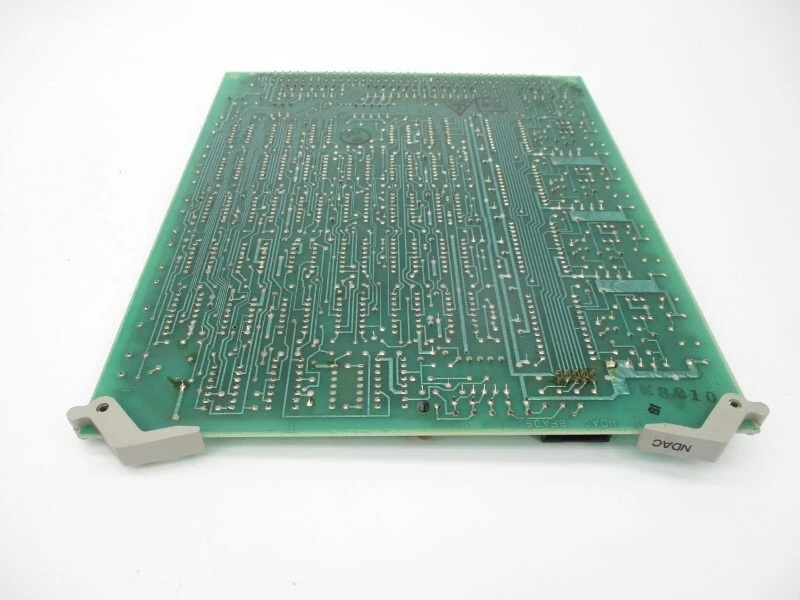

The DS3800NDAC1B1C is a daughterboard-grade D/A converter that occupies a 6BA06 slot in the GE Speedtronic Mark IV rack. It receives parallel digital words (speed demand, temperature bias, load set-point) from the CPU over the VME back-plane, converts them to precision analog voltages or currents, and drives servo amplifiers, IGV positioners, and remote indicators throughout the turbine island. The card is hardware-configured (no firmware download) and deterministic, making it suitable for safety-related control loops when triple-redundant.

Physical implementation includes 12-bit DACs, op-amp output stages, galvanic isolation, and TVS surge suppressors. Eight front-access trim pots allow offset and gain calibration without board removal; nine test points enable oscilloscope probing of output, clock, and power rails. Five LEDs (4 red + 1 amber) give real-time channel health—no multimeter required during commissioning.

Environmental qualification meets –20 °C to +70 °C, IEEE 344 seismic, and CE emissions, giving >25-year service life in baseload duty.

DS3800NDAC1B1C

DS3800NDAC1B1C: Technical Specifications

-

Model Number: DS3800NDAC1B1C

-

Manufacturer: General Electric (GE Energy)

-

Product Type: Digital-to-Analog Output Card (DAC)

-

System Compatibility: Speedtronic Mark IV (6BA06 slot)

-

Output Ranges:

-

Current: 4–20 mA (live zero) or 0–20 mA (jumper-selectable)

-

Voltage: 0–10 V (jumper-selectable)

-

-

Resolution: 12-bit monotonic, ±½ LSB INL

-

Settling Time: <5 µs to ±0.1 % for 10 V step

-

Load Capability: 750 Ω (current mode), 5 kΩ (voltage mode)

-

Isolation: 1500 V AC channel-to-ground, 500 V channel-to-channel

-

Update Rate: 100 kHz max (jumper-selectable 1 kHz, 10 kHz, 100 kHz)

-

Trimmers: Offset and gain pots per channel (front-access)

-

Memory: 20+ EPROM/EEPROM devices (reprogrammable)

-

Test Points: 9 TP (output, clock, power)

-

LEDs: 4 red (channel status), 1 amber (output active)

-

Connectors: 20-pin ribbon, keyed, gold-plated

-

Power Rails: +5 V logic, ±15 V analog, <1 W per channel

-

Temp Range: -20 °C to +70 °C operational, -55 °C to +125 °C storage

-

Certifications: CE, RoHS, IEEE 344 form-factor compatible

Core Features & Customer Value

Microsecond-Fast Settling for Servo Loops

<5 µs settling to 0.1 % enables 10 kHz servo-loop bandwidth—critical for IGV positioners and fuel-metering servo valves that must track speed/load transients without overshoot.

<5 µs settling to 0.1 % enables 10 kHz servo-loop bandwidth—critical for IGV positioners and fuel-metering servo valves that must track speed/load transients without overshoot.

Hot-Swappable in TMR Strings

Redundant Mark IV allows online replacement of one DAC card; remaining two legs continue voting. MTTR is <5 min—no outage, no load shed, no restart required.

Redundant Mark IV allows online replacement of one DAC card; remaining two legs continue voting. MTTR is <5 min—no outage, no load shed, no restart required.

Field-Calibrated Without Software

Offset and gain trimmers compensate for valve hysteresis, cable resistance, or amplifier drift—technician can trim full-scale and zero using only a screwdriver and a DMM, reducing commissioning time by >50 %.

Offset and gain trimmers compensate for valve hysteresis, cable resistance, or amplifier drift—technician can trim full-scale and zero using only a screwdriver and a DMM, reducing commissioning time by >50 %.

Surge-Hardened for Turbine Deck

TVS diodes and opto-isolators clamp >500 V spikes from lightning, VFD switching, or exciter flash-over. 1500 V isolation prevents ground-fault propagation to CPU cards, reducing unplanned replacement by >60 % compared with non-isolated DACs.

TVS diodes and opto-isolators clamp >500 V spikes from lightning, VFD switching, or exciter flash-over. 1500 V isolation prevents ground-fault propagation to CPU cards, reducing unplanned replacement by >60 % compared with non-isolated DACs.

DS3800NDAC1B1C

Typical Applications

Gas Turbine Fuel & IGV Control

Drives ±10 V input to Woodward servo amplifiers for fuel-metering valves and IGV hydraulic actuators in Frame 7/9 units. 12-bit resolution achieves 0.025 % fuel-flow accuracy, essential for NOx compliance and part-load heat-rate optimization.

Drives ±10 V input to Woodward servo amplifiers for fuel-metering valves and IGV hydraulic actuators in Frame 7/9 units. 12-bit resolution achieves 0.025 % fuel-flow accuracy, essential for NOx compliance and part-load heat-rate optimization.

Steam Turbine Governor & Extraction Control

4–20 mA output drives Moog servo valves on governor and extraction pressure loops. Deterministic update rate prevents valve dither and mechanical wear, extending servo life to >100 k hours.

4–20 mA output drives Moog servo valves on governor and extraction pressure loops. Deterministic update rate prevents valve dither and mechanical wear, extending servo life to >100 k hours.

Remote Indication & DCS Interface

0–10 V scaled signals feed plant DCS for remote load meters, temperature indicators, and vibration displays. Isolation eliminates ground-loop noise that would corrupt 4–20 mA loops in large combined-cycle sites.

0–10 V scaled signals feed plant DCS for remote load meters, temperature indicators, and vibration displays. Isolation eliminates ground-loop noise that would corrupt 4–20 mA loops in large combined-cycle sites.