Description

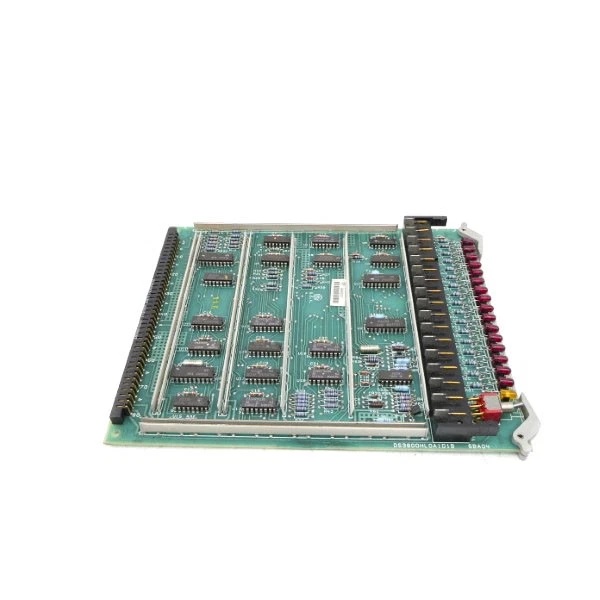

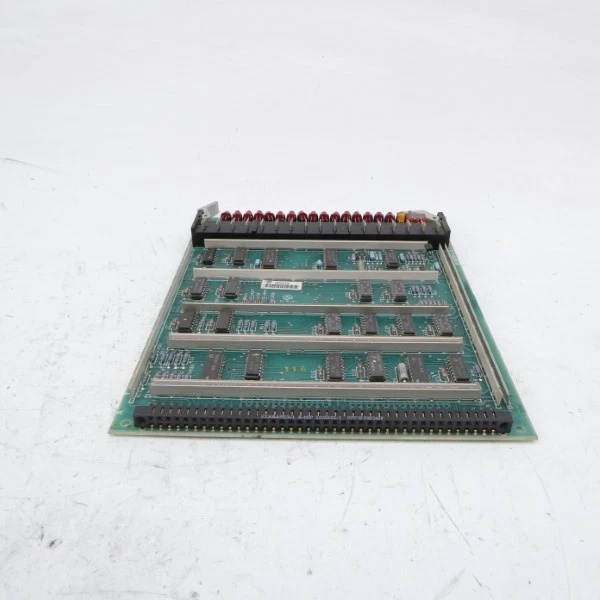

DS3800NCIC1C1C: Product Overview

The board operates as a communication hub and data concentrator within the Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this unit manages the high-speed exchange of data between the central microprocessor complex and distributed I/O nodes located throughout the turbine skid and auxiliary enclosures. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, ensuring that data from field instruments reaches the control algorithms with deterministic timing while maintaining synchronization across redundant processing paths.

As a node communication interface, the unit provides the protocol translation and data buffering necessary to bridge different communication architectures within the control system. It receives time-critical data from remote I/O modules—such as exhaust gas thermocouples, vibration monitors, and servo valve positioners—and concentrates these inputs for efficient transfer across the backplane to the main processors. Simultaneously, it distributes control commands from the central processors to output modules controlling fuel valves, auxiliary motors, and protection relays.

The board features dual high-density modular connectors that interface with the Mark IV backplane, providing redundant pathways for data exchange and ensuring continued operation even if one connector path experiences degradation. Socketed EPROM modules contain the communication protocols, data mapping tables, and node addressing schemes specific to the turbine installation. Hardware configuration jumpers allow field adaptation to different network topologies and data rates without firmware modifications.

This board belongs to the DS3800 series of the Mark IV platform, deployed across heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed architecture requires deterministic microsecond-level data exchange between nodes; this communication interface provides the timing precision and buffering capacity necessary to maintain real-time control performance across geographically dispersed I/O.

GE DS3800HLOA1D1B

DS3800NCIC1C1C: Technical Specifications

-

Model Number: DS3800NCIC1C1C

-

Manufacturer: General Electric

-

Product Type: Node Communication Interface Card

-

Series: GE Speedtronic Mark IV

-

Architecture: Triple Modular Redundant (TMR) compatible

-

Function: Data concentration and node communication management

-

Backplane Interface: Dual high-density modular connectors (AMD 218A4553-1 compatible)

-

Communication Protocol: Proprietary Mark IV node bus protocol with configurable data rates

-

Memory: EPROM sockets for communication firmware and node mapping tables

-

Data Buffering: Integrated buffer memory for deterministic data transfer

-

Configuration: Hardware jumpers for node address and network topology selection

-

Status Indication: Diagnostic LEDs for communication activity and fault detection

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Vibration/Shock: 5 g vibration / 50 g shock (per Mark IV specifications)

-

Mounting: Standard Mark IV rack slot with integrated retention levers

Part 4: Core Features & Customer Value

Deterministic Data Concentration for Real-Time Control: The board provides the buffering and prioritization logic necessary to manage data flow from multiple remote I/O nodes without introducing latency that could compromise turbine protection. By concentrating data from distributed sensors into efficient packets for backplane transmission, the board ensures that critical protection signals—such as overspeed detection or vibration alarms—receive priority handling while routine monitoring data continues to flow. For control system engineers, this deterministic performance guarantees that the distributed architecture meets the hard real-time requirements necessary for turbine safety systems.

Protocol Isolation and Translation: Acting as a protocol gateway, the board translates between the specific communication formats used by remote I/O modules and the standardized backplane protocol used by the main processors. This isolation prevents communication faults on remote nodes from propagating into the central control system, maintaining stability even when field wiring experiences electrical noise or grounding issues. Field technicians benefit from this isolation during troubleshooting, as it allows individual nodes to be disconnected and tested without disrupting the overall control system operation.

Flexible Node Configuration Architecture: The combination of EPROM-based firmware and hardware jumpers allows the same physical board to support different network topologies—whether star, bus, or ring configurations—without hardware changes. This flexibility accommodates the varying physical layouts of turbine installations, from compact skid-mounted packages to sprawling multi-enclosure power plant configurations. Facilities can standardize on a single board type for all node communication roles, reducing spare parts inventory while supporting diverse installation requirements through configuration rather than hardware variants.

Robust Error Detection and Recovery: Integrated diagnostic circuitry continuously monitors data integrity, detecting communication errors, node timeouts, and buffer overflows. When errors are detected, the board implements automatic retry algorithms and can isolate faulty nodes from the network to prevent data corruption. The diagnostic LEDs provide immediate visual indication of network health, allowing maintenance personnel to identify communication faults without requiring specialized protocol analyzers or laptop connections.

Hot-Swappable Redundancy for Continuous Availability: The board supports replacement within the Mark IV TMR architecture, allowing technicians to restore communication capabilities without turbine shutdown. In redundant configurations, the remaining two channels maintain data flow while the affected channel is serviced, ensuring that critical monitoring and control functions remain available. The retention lever system ensures positive mechanical engagement despite turbine vibration, preventing intermittent connections that could cause sporadic communication failures.

GE DS3800HLOA1D1B

Part 5: Typical Applications

Gas Turbine Distributed I/O Networks:

The board is deployed in GE Frame 5, 6, and 7 gas turbines to manage communication between the main control rack and remote I/O stations located on the turbine skid, in the fuel forwarding module, and at the generator terminals. In these applications, the node communication interface concentrates data from exhaust temperature thermocouple modules, vibration monitoring cards, and servo valve drivers distributed around the turbine package. It ensures that the central processor receives synchronized data from all nodes within the millisecond timing requirements necessary for combustion control and protection, despite the physical separation of up to 100 feet between the control room and field devices.

The board is deployed in GE Frame 5, 6, and 7 gas turbines to manage communication between the main control rack and remote I/O stations located on the turbine skid, in the fuel forwarding module, and at the generator terminals. In these applications, the node communication interface concentrates data from exhaust temperature thermocouple modules, vibration monitoring cards, and servo valve drivers distributed around the turbine package. It ensures that the central processor receives synchronized data from all nodes within the millisecond timing requirements necessary for combustion control and protection, despite the physical separation of up to 100 feet between the control room and field devices.

Steam Turbine Control System Integration:

In steam turbine modernization projects within paper mills and petrochemical facilities, this board facilitates the integration of new Mark IV controls with existing field wiring through distributed I/O concentrators. It manages the communication protocol between modern microprocessor-based controllers and legacy I/O hardware, allowing retrofits to proceed without replacing every field transmitter. The board’s configurable protocol translation accommodates the specific data formats of older turbine instrumentation while presenting standardized data to the new control algorithms, reducing commissioning time and preserving proven field device investments.

In steam turbine modernization projects within paper mills and petrochemical facilities, this board facilitates the integration of new Mark IV controls with existing field wiring through distributed I/O concentrators. It manages the communication protocol between modern microprocessor-based controllers and legacy I/O hardware, allowing retrofits to proceed without replacing every field transmitter. The board’s configurable protocol translation accommodates the specific data formats of older turbine instrumentation while presenting standardized data to the new control algorithms, reducing commissioning time and preserving proven field device investments.

Aeroderivative Package Communication Management:

For LM6000 and LM2500 units, the board manages the high-speed data exchange necessary for the compact, highly integrated control packages typical of aeroderivative installations. It coordinates communication between the main control processor and package-mounted I/O modules handling inlet guide vanes, fuel forwarding systems, and compartment ventilation controls. The board’s deterministic timing ensures that the fast-acting control sequences required for aeroderivative peaking applications—where startup to full load may occur within ten minutes—are not delayed by communication bottlenecks.

For LM6000 and LM2500 units, the board manages the high-speed data exchange necessary for the compact, highly integrated control packages typical of aeroderivative installations. It coordinates communication between the main control processor and package-mounted I/O modules handling inlet guide vanes, fuel forwarding systems, and compartment ventilation controls. The board’s deterministic timing ensures that the fast-acting control sequences required for aeroderivative peaking applications—where startup to full load may occur within ten minutes—are not delayed by communication bottlenecks.

Combined Cycle Plant Multi-Enclosure Networks:

In combined cycle power plants where the Mark IV controls must interface with heat recovery steam generators (HRSG), steam turbine controls, and balance-of-plant equipment across multiple control enclosures, this board serves as the communication bridge between geographically separated control nodes. It manages the data routing necessary to coordinate turbine operation with heat recovery equipment, ensuring that steam turbine loading remains synchronized with gas turbine exhaust temperature conditions. The board’s error detection capabilities maintain data integrity across the longer cable runs typical of these large plant installations.

In combined cycle power plants where the Mark IV controls must interface with heat recovery steam generators (HRSG), steam turbine controls, and balance-of-plant equipment across multiple control enclosures, this board serves as the communication bridge between geographically separated control nodes. It manages the data routing necessary to coordinate turbine operation with heat recovery equipment, ensuring that steam turbine loading remains synchronized with gas turbine exhaust temperature conditions. The board’s error detection capabilities maintain data integrity across the longer cable runs typical of these large plant installations.

Safety Instrumented System (SIS) Communication:

Within the Mark IV’s integrated protection architecture, this board manages the communication of safety-critical data between protective input modules, voting logic processors, and trip output circuits. It ensures that safety-related inputs and voting decisions are transmitted with the deterministic timing required for SIL-rated protection systems, maintaining the microsecond-level coordination necessary for emergency shutdown sequences. The board’s ability to isolate faulty nodes prevents a single communication fault from compromising the availability of protective functions across all three redundant channels.

Within the Mark IV’s integrated protection architecture, this board manages the communication of safety-critical data between protective input modules, voting logic processors, and trip output circuits. It ensures that safety-related inputs and voting decisions are transmitted with the deterministic timing required for SIL-rated protection systems, maintaining the microsecond-level coordination necessary for emergency shutdown sequences. The board’s ability to isolate faulty nodes prevents a single communication fault from compromising the availability of protective functions across all three redundant channels.