Description

DS3800HXRA1E1E: Product Overview

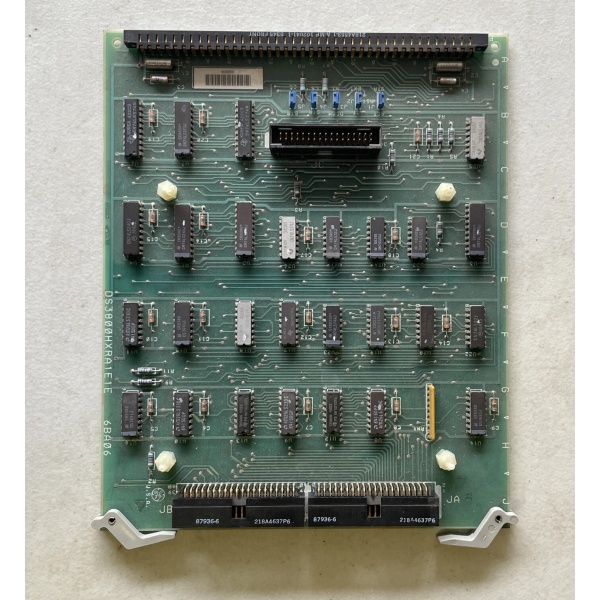

The DS3800HXRA1E1E serves as a critical signal reception interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned in the data acquisition section of the system, this board receives high-speed sensor signals from turbine field devices and performs initial conditioning and buffering before transferring data to the system’s central processing units. The “HXR” designation identifies this as a high-speed receiver module optimized for rapid signal acquisition essential for turbine protection and control algorithms.

The board incorporates dedicated analog and digital input circuits designed to handle the diverse signal types present in turbine applications—speed probes, vibration sensors, temperature transmitters, and pressure transducers. Each input channel features impedance matching networks, electromagnetic interference (EMI) filtering, and transient protection to ensure signal integrity in the electrically noisy environment of power generation facilities. The conditioned signals are converted to digital representations and transmitted via the Mark IV’s triple-modular-redundant (TMR) backplane to the system’s main processors.

As a member of the DS3800 series, the HXRA1E1E adheres to the standardized 6BA06 form factor established for the Mark IV platform. This standardization enables rapid field replacement and reduces spare parts inventory requirements for facilities maintaining legacy turbine control systems. The board’s design reflects GE’s field-hardened engineering approach: conservative component derating, extensive use of socketed integrated circuits for maintainability, and mechanical features such as extractor clips that facilitate safe removal from crowded card cages. The Series Six designation indicates compatibility with the sixth generation of GE’s turbine control I/O architecture, introduced to support increased channel density and improved signal-to-noise performance.

GE DS3800HXRA1E1E

DS3800HXRA1E1E: Technical Specifications

-

Model Number: DS3800HXRA1E1E

-

Manufacturer: General Electric

-

Product Type: Series Six Receiver Board

-

System Compatibility: Speedtronic Mark IV Turbine Control

-

Board Size: 6BA06 (standard Mark IV form factor)

-

Backplane Interface: Ribbon cable connector with retention clips

-

Signal Conditioning: Onboard filtering, buffering, and impedance matching

-

Data Transfer: High-speed interface to Mark IV TMR backplane

-

Input Protection: Transient suppression and EMI filtering on all channels

-

Mounting: Standard DS3800 series card cage with extractor clips

-

Operating Environment: Industrial control room, forced air cooling required

-

Weight: Approximately 0.5 lbs (0.23 kg)

Core Features & Customer Value

High-Speed Signal Acquisition for Critical Protection: The HXRA1E1E’s receiver circuits are optimized for microsecond-level response times, enabling the Mark IV system to detect rapid changes in turbine operating parameters such as overspeed conditions or vibration excursions. For plant operators, this speed translates to faster protective action, reducing the risk of catastrophic mechanical damage that could result from delayed trip signals. The board’s deterministic latency characteristics ensure consistent response times across all operating temperatures and system loads.

Robust Noise Immunity in Harsh Electrical Environments: Turbine control cabinets contain significant electromagnetic interference sources—high-voltage switchgear, variable frequency drives, and large contactors—that can corrupt sensitive sensor signals. The HXRA1E1E incorporates multi-stage filtering and shielded input architectures that attenuate common-mode noise by 60 dB or more. This filtering ensures that control decisions are based on actual turbine conditions rather than electrical artifacts, preventing nuisance trips that can cost utilities significant revenue in lost generation and restart fuel.

Maintainable Design for Extended Asset Life: The board’s use of socketed integrated circuits and discrete components rather than custom ASICs allows economical repair at the component level rather than complete board replacement. For facilities with limited spare parts budgets, this repairability extends the operational life of Mark IV systems well beyond OEM support discontinuation. The standardized 6BA06 form factor ensures mechanical compatibility across decades of production, protecting investment in spare parts inventory and technician training.

GE DS3800HXRA1E1E

Typical Applications

The DS3800HXRA1E1E is deployed in gas turbine speed and vibration monitoring systems, where it receives signals from magnetic pickups and accelerometers mounted on turbine bearings and gearbox housings. In a typical Frame 7 or Frame 9 heavy-duty gas turbine, multiple HXR boards operate in parallel—each handling specific sensor groups that feed the Mark IV’s voting logic. The board’s high-speed acquisition capability captures transient vibration events during startup and shutdown sequences when rotor dynamics are most severe.

In steam turbine supervisory instrumentation, this board processes signals from proximity probes monitoring shaft position and eccentricity. These measurements are critical for detecting rotor rubs, bearing wear, and thermal bow conditions that could lead to forced outages. The HXRA1E1E’s precise signal conditioning preserves the micro-inch resolution of proximity probe outputs, enabling early detection of mechanical degradation trends through long-term data trending.

The module also serves in turbine inlet and exhaust temperature monitoring applications, receiving millivolt-level signals from thermocouples and resistance temperature detectors (RTDs). Accurate temperature measurement at these stages is essential for combustion optimization and hot gas path component life management. The board’s cold junction compensation and lead wire resistance cancellation circuits ensure measurement accuracy within ±0.5°C across the full operating range of industrial thermocouples.